Fuel injectin valve

A fuel injection valve and fuel supply technology, which is applied to fuel injection pumps, fuel injection devices, special fuel injection devices, etc., can solve problems such as damage to internal combustion engines, and achieve the effect of reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

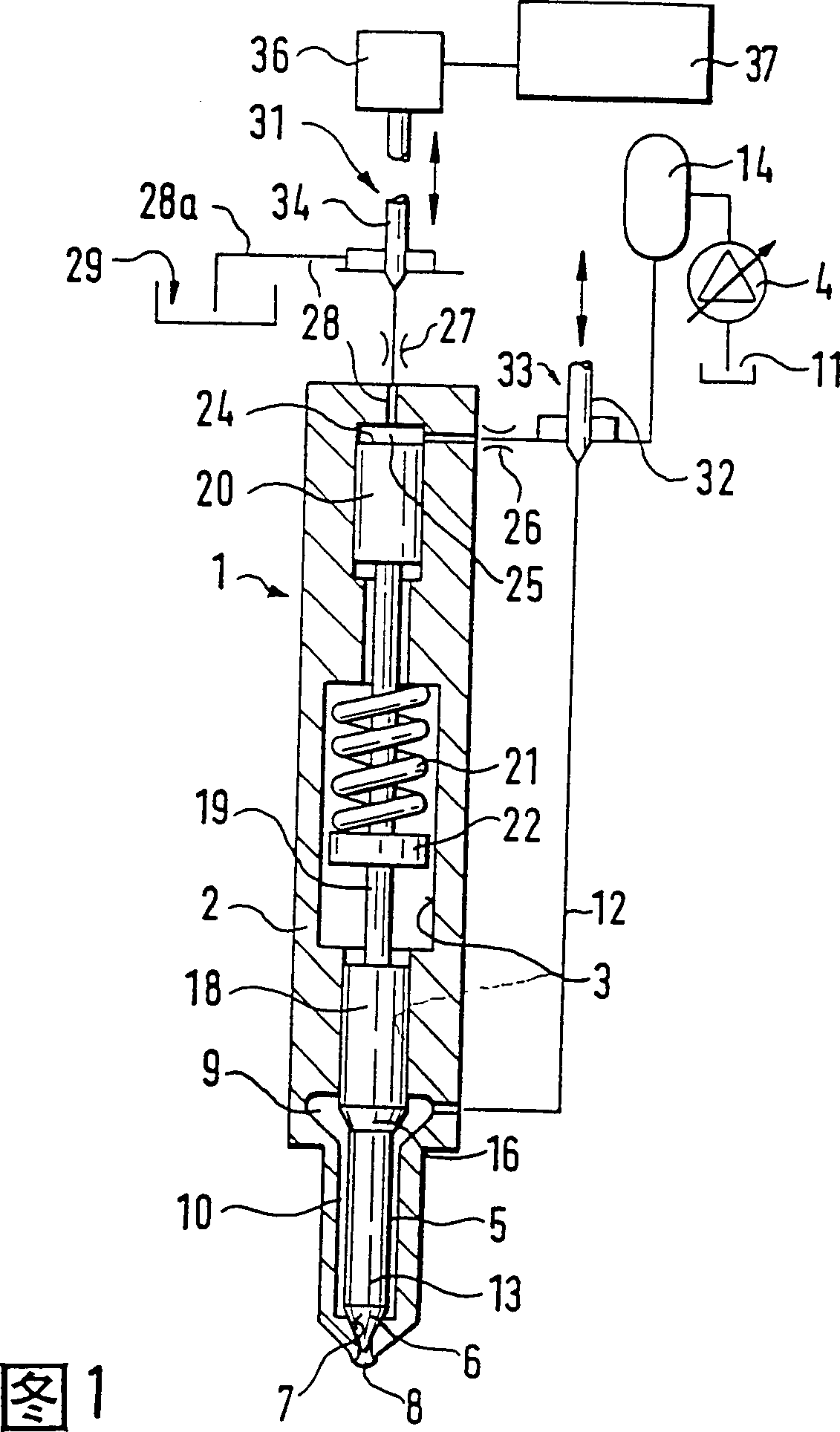

[0016] FIG. 1 shows a simple view of an injection valve 1 having an injection valve housing 2 with a bore 3 in which an injection valve element 5 is guided, which The fuel injection valve element 5 has a conical sealing surface 6 at one end, which cooperates with a conical valve seat 7 at the end of the bore. Downstream of the valve seat 7 are arranged oil injection openings 8 which are separated from a pressure chamber 9 when the sealing surface 6 is on the valve seat 7 . The pressure chamber 9 extends on an annular space 10 around the part 13 of the fuel injection valve element having a smaller diameter upstream of the sealing surface 6 as far as the valve seat 7 . The pressure chamber 9 can communicate via a pressure line 12 with a high-pressure oil source in the form of a high-pressure oil reservoir 14, which is placed at the injection pressure from the oil reservoir 11 by, for example, a high-pressure oil delivery pump 4 with a variable fuel delivery ratio. The lower fue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com