Copper-aluminum composite material heat dissipation structure for high-power-consumption single board and installation method of copper-aluminum composite material heat dissipation structure

A technology of copper-aluminum composite material and heat dissipation structure, which is applied in the construction parts of electrical equipment, cooling/ventilation/heating transformation, electrical components, etc., which can solve the problems of failure to operate normally, high power consumption, and heat dissipation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

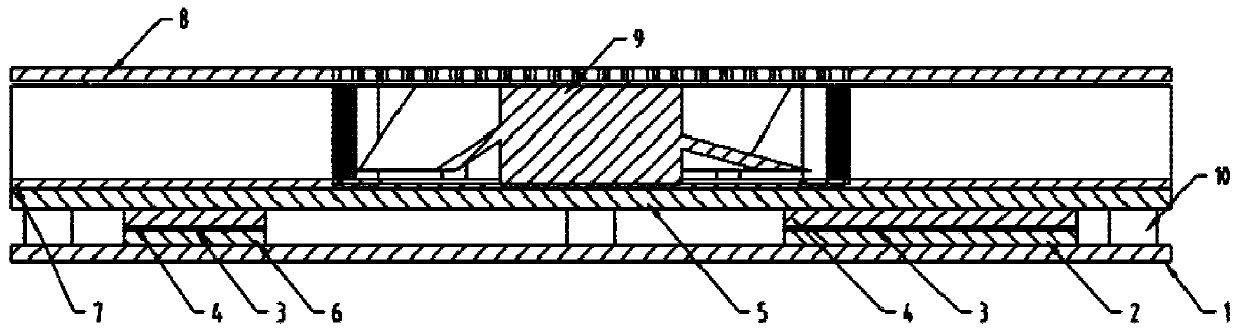

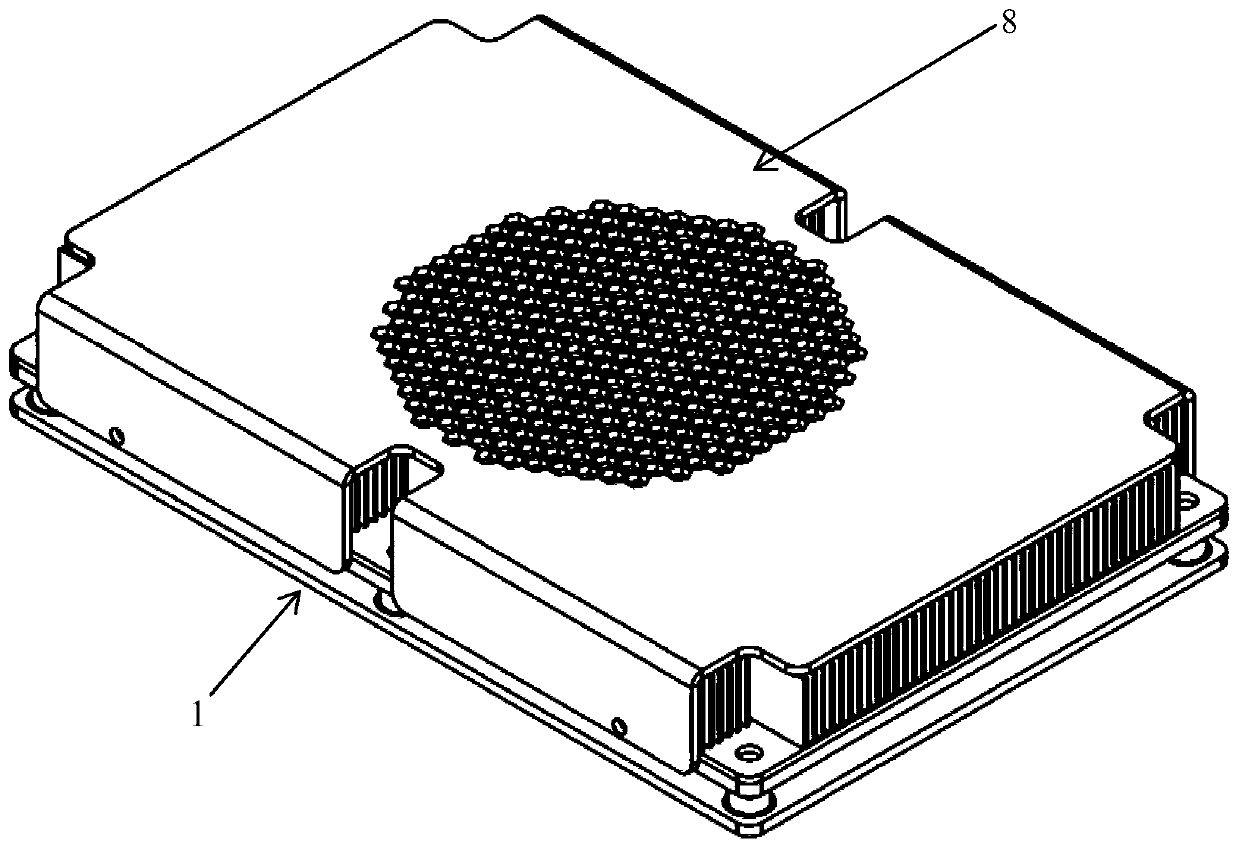

[0031] Such as figure 1 , figure 2 As shown, in this embodiment, a copper-aluminum composite heat dissipation structure for high-power consumption veneers is specifically provided. heat dissipation requirements, which include a high power consumption single board PCB1 and a chipset located on the high power consumption single board PCB1, the high power consumption single board PCB1 used in this embodiment is mainly located on the high power consumption single board The CPU chip 2 and the north bridge chip 6 on the board PCB1, the CPU chip 2 and the north bridge chip 6 are high power consumption chips, which will generate a lot of heat during operation. It also includes a copper-aluminum composite radiator installed on the high-power consumption single-board PCB1, and the high-power consumption single-board PCB1 is connected to the copper-aluminum composite radiator through a plurality of support columns 10, and each support column 10 There are PCB mounting holes through wh...

Embodiment 2

[0039] On the basis of the copper-aluminum composite material heat dissipation structure for high power consumption boards provided in Embodiment 1, this embodiment also provides a copper-aluminum composite material heat dissipation structure for high power consumption boards The installation method, the installation method includes the following:

[0040] (1) The copper-aluminum composite heat sink is prepared by welding process. The copper-aluminum composite heat sink is formed by the friction welding process of the copper base 5 and the aluminum heat dissipation fin 7. The reason why the friction welding process is adopted is that it is compared with the general heat dissipation structure. The copper substrate is used as the heat sink and the aluminum material is used as the heat dissipation fin. The traditional welding process between copper and aluminum leads to a large thermal resistance between copper and aluminum, which affects the heat dissipation efficiency;

[0041]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com