Continuous piercing machine for auricularia fungus bags

A punching machine and agaric fungus technology, applied in horticulture, botany equipment and methods, plant cultivation, etc., can solve the problems of low punching efficiency, time-consuming and labor-intensive punching of fungus bags, etc., and achieve the effect of improving the punching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

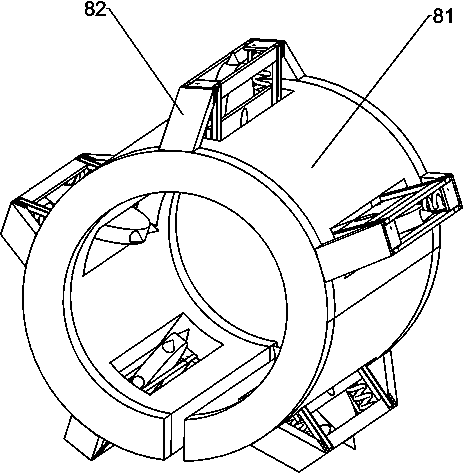

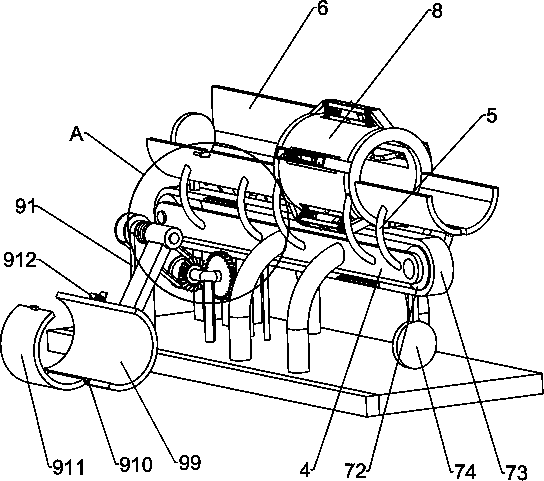

[0025] A continuous punching machine for fungus bags, such as Figure 1-5 As shown, it includes a base 1, a bracket 2, a first connecting column 3, a main body mounting plate 4, a second connecting column 5, a guide rail 6, a moving mechanism 7 and a punching mechanism 8, and the left side of the front side of the top of the base 1 is connected with a The bracket 2, the left and right sides of the top of the base 1 are connected with two first connecting columns 3, the tops of the two first connecting columns 3 on the left and right sides are connected with a main body mounting plate 4, and the two main body mounting plates 4 are connected to each other. A moving mechanism 7 is installed, and the outer surface of the main body mounting plate 4 is connected with a plurality of second connecting columns 5, and guide rails 6 are connected between the tops of the plurality of second connecting columns 5, and the bottom of the guide rails 6 has a through groove, and the guide rails ...

Embodiment 2

[0030] On the basis of Example 1, such as figure 1 , figure 2 with Image 6 As shown, also includes feeding mechanism 9, and feeding mechanism 9 includes fixed mounting block 91, rotating shaft 92, transmission belt group 93, bevel gear 94, transmission gear 95, V-shaped fixed frame 96, locking tooth group 97, torque Spring 98, swing arm 99, connecting shaft 910, arc cover plate 911, buckle 912 and trip lever 913, the top of base 1 on the right side of support 2 is connected with fixed installation block 91, and the top of base 1 on the left side of fixed installation block 91 A V-shaped fixed mount 96 is connected, and the left side of the V-shaped fixed mount 96 is rotatably connected with a transmission gear 95, and the front side of the V-shaped fixed mount 96 is rotatably connected with a bevel gear 94, and the bevel gear 94 meshes with the transmission gear 95. The right side of transmission belt 73 is connected with two latching tooth groups 97, and latching tooth gr...

Embodiment 3

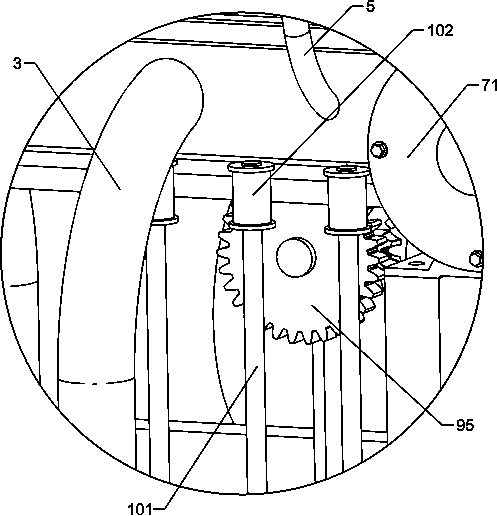

[0033] On the basis of Example 2, such as figure 1 with Figure 7 As shown, it also includes a limit structure 10, the limit structure 10 includes a fixed rod 101 and a pulley 102, a plurality of fixed rods 101 are connected to the top of the base 1 on the left side of the V-shaped fixed frame 96, and the top of the fixed rod 101 is rotatably connected A pulley 102 is provided, and the pulley 102 is in contact with the left side of the drive belt 73 .

[0034] The pulley 102 is in contact with the left side of the transmission belt 73, which can prevent the transmission belt 73 from shaking left and right when it is stressed, so that the locking tooth set 97 and the transmission gear 95 can be tightly meshed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com