Processing method of white tea fused with black tea aroma and the white tea

A processing method and technology of white tea, which is applied in tea treatment before extraction, etc., can solve the problems of dead green tea leaves and poor quality tea leaves, and achieve the effect of milky aroma, quality improvement, and inner quality aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for processing white tea that combines the fragrance of black tea, comprising the following steps:

[0033] S1. Picking fresh leaves from new shoots of Fuding Dahao tea tree variety with one bud, two leaves and three leaves;

[0034] S2, spreading cool;

[0035] S3, a programmed withering;

[0036] Spread the fresh leaves evenly and thinly on the clean and transparent cool green equipment, and place them in the program-controlled withering room with an ambient temperature of 16°C-20°C and a relative humidity of 60%-80%, so that the weight of the green tea can be reduced by 50%-60% %;

[0037] S4, kneading;

[0038] Put the withered leaves in the kneading machine, fill it with tea greens and cover the machine cover to knead, and start the kneading for 5-10 minutes after the machine cover touches the tea leaves;

[0039] S5, secondary programmed withering;

[0040] Spread the rolled leaves on the cool green equipment, place them in a program-controlled withe...

Embodiment 2

[0046] A method for processing white tea that combines the fragrance of black tea, comprising the following steps:

[0047] S1, Fuyun No. 6 tea tree variety with one bud, two leaves and three leaves;

[0048] S2, spreading cool;

[0049] S3, a programmed withering;

[0050] Spread the fresh leaves evenly and thinly on the clean and transparent cool green equipment, and place them in the program-controlled withering room with an ambient temperature of 16°C-20°C and a relative humidity of 60%-80%, so that the weight of the green tea can be reduced by 50%-60% %;

[0051] S4, kneading;

[0052] Put the withered leaves in the kneading machine, fill it with tea greens and cover the machine cover to knead, and start the kneading for 5-10 minutes after the machine cover touches the tea leaves;

[0053] S5, secondary programmed withering;

[0054] Spread the rolled leaves on the cool green equipment, place them in a program-controlled withering room with an ambient temperature of ...

Embodiment 3

[0060] A method for processing white tea that combines the fragrance of black tea, comprising the following steps:

[0061] S1. Picking fresh leaves from new shoots of Fuan Dabai tea tree varieties with one bud, two leaves and three leaves;

[0062] S2, spreading cool;

[0063] S3, a programmed withering;

[0064] Spread the fresh leaves evenly and thinly on the clean and transparent cool green equipment, and place them in the program-controlled withering room with an ambient temperature of 16°C-20°C and a relative humidity of 60%-80%, so that the weight of the green tea can be reduced by 50%-60% %;

[0065] S4, kneading;

[0066] Put the withered leaves in the kneading machine, fill it with tea greens and cover the machine cover to knead, and start the kneading for 5-10 minutes after the machine cover touches the tea leaves;

[0067] S5, secondary programmed withering;

[0068] Spread the rolled leaves on the cool green equipment, place them in a program-controlled withe...

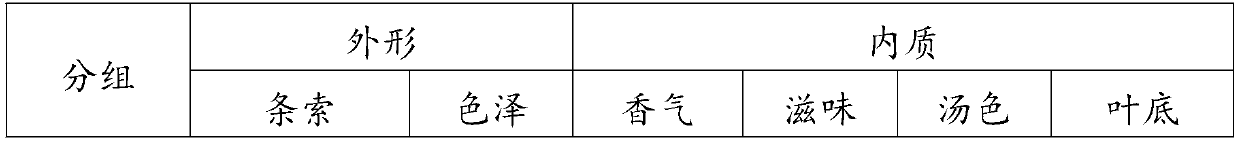

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com