Copper sulfide cobalt ore potential-pH regulation flotation method

A technology for copper sulfide and cobalt ore, applied in flotation, solid separation, etc., can solve the problems of large fluctuation of metal recovery rate, low cobalt grade of concentrate, and unstable metal recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

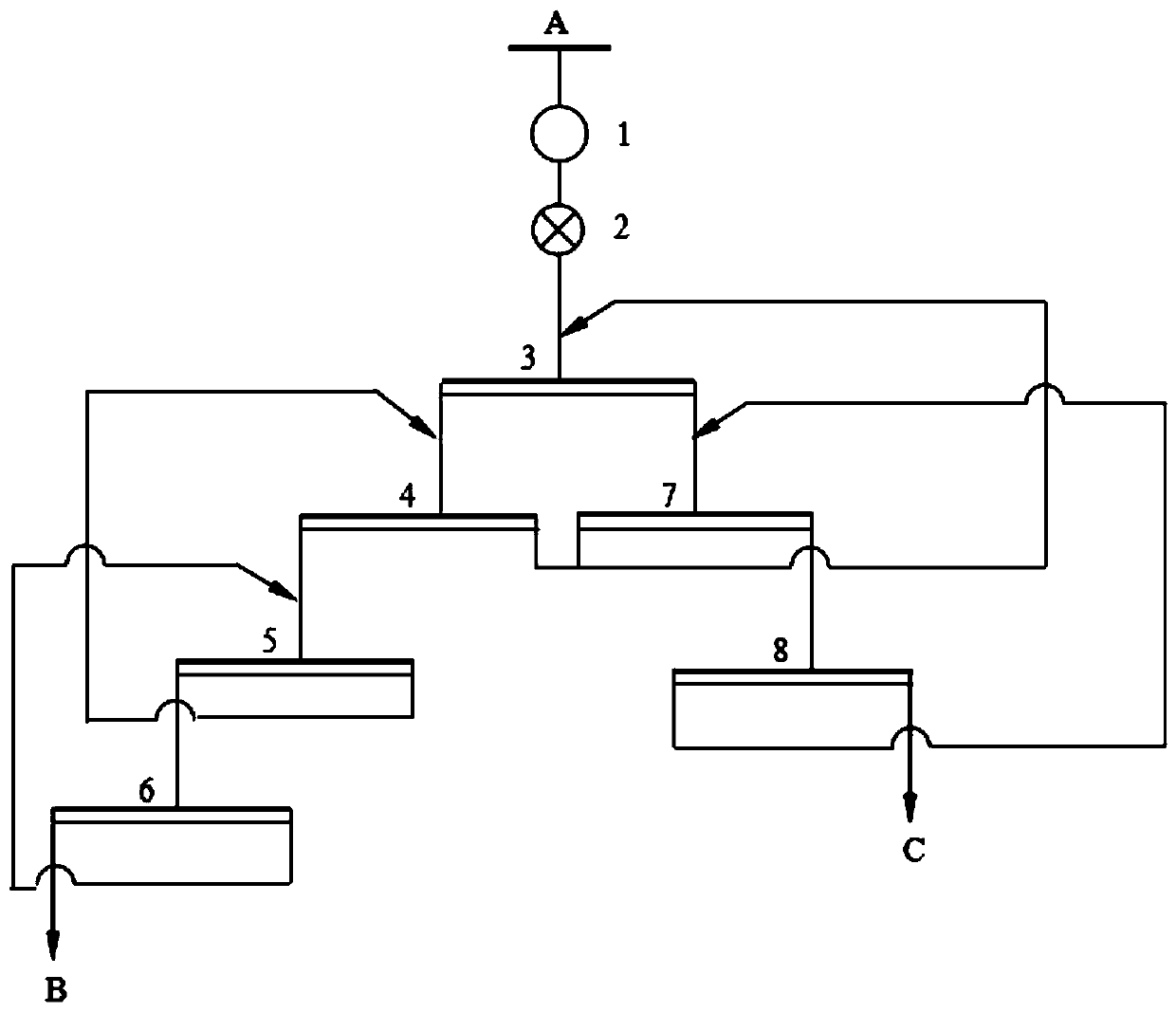

[0036] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0037] The copper-cobalt sulfide ore potential-pH regulating flotation method of the present invention is to finally obtain the copper-cobalt sulfide concentrate product by regulating the pH and potential of the ore pulp in the flotation process, combining with a suitable chemical system and process flow.

[0038] refer to figure 1 Shown, flotation method of the present invention comprises the following steps:

[0039] S1: Grinding - Classification

[0040] Through crushing, grinding and classification, the copper-cobalt sulfide ore ore is ground, that is, the raw ore A is ground, and the copper-cobalt sulfide ore slurry that meets the flotation requirements is obtained, and the slurry enters the flotation stirring tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com