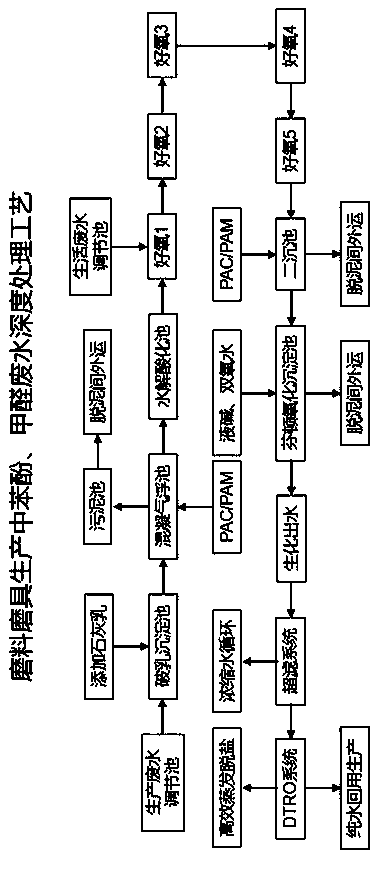

Advanced treatment process for phenolic resin production wastewater in abrasive grinding tool production

A technology of phenolic resin and abrasives, which is applied in the direction of neutralization water/sewage treatment, water/sewage treatment, natural water body treatment, etc. It can solve problems such as troublesome operation, complicated process, and high treatment cost, so as to save land and solve problems. The effects of secondary pollution and stable effluent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Such as figure 1 As shown, the phenolic resin wastewater produced in the production process of an abrasive abrasive tool manufacturer is subjected to advanced treatment. The main source of the phenolic resin wastewater is: a. The original cloth treatment wastewater. The main components of the wastewater are suspended solids, starch, PVA and a small amount of alkali liquid; the formaldehyde content is 10mg / L, the phenol content is 480mg / L, and the COD content is 760mg / L;

[0052] b. Production line waste water, mainly refers to the disposable waste water produced by cleaning equipment that contains harmful components, the formaldehyde content is 20mg / L, the phenol content is 968mg / L, and the COD content is 7450mg / L;

[0053] c. Wastewater from the compounding workshop mainly refers to the waste water produced by resin batching and containing harmful components. The content of formaldehyde is 150mg / L, the content of phenol is 11025-11205mg / L, and the content of COD is 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com