Impact-resistant toughened PVC pipe fitting and preparation method thereof

A PVC pipe and impact-resistant technology, applied in the field of impact-resistant and toughened PVC pipe fittings, impact-resistant and toughened PVC pipe fittings preparation field, can solve problems such as inability to see neat lines, opaque PVC pipes, poor product compatibility, etc. Production labor cost, high production quality, and the effect of improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

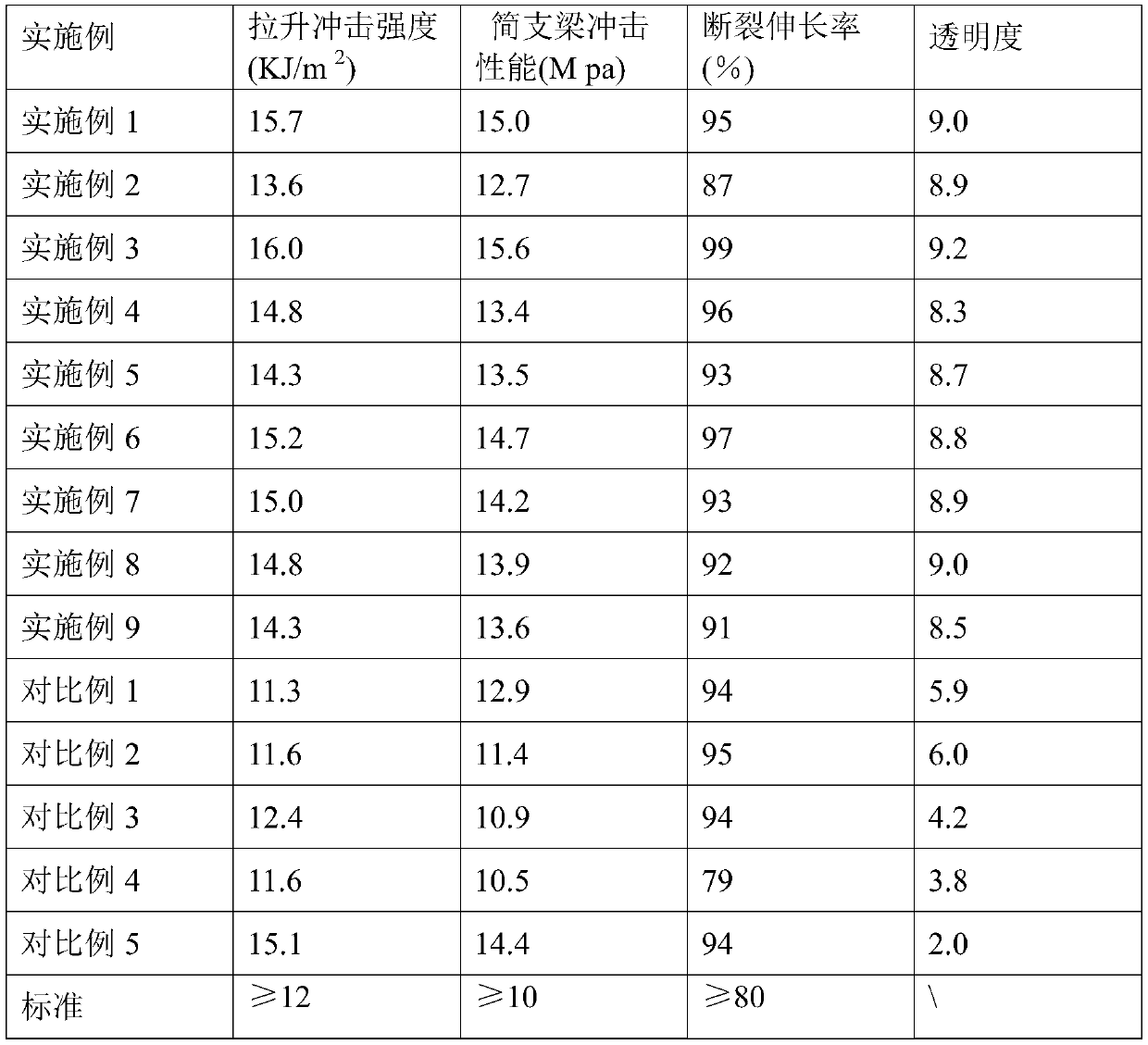

Examples

Embodiment 1

[0030] A preparation method for impact-resistant and toughened PVC pipe fittings, comprising the following steps:

[0031] SG~7 type PVC resin 100 parts

[0032] HL~60 type processing aid 4.2 parts

[0033] MBS~66 type impact modifier 5 parts

[0034] Calcium zinc heat stabilizer 6.1 parts

[0035] PCC~P type superfine calcium carbonate 11.5 parts

[0036] SR~240 type titanium dioxide 2.1 parts

[0037] DS~65 type dioctyl ester 4.2 parts

[0038] LA~W95 type lubricant 0.6 parts

[0039] Add the weighed raw materials into the high-speed mixer and stir. The temperature of the high-speed mixer is controlled at 115°C, the stirring time is 20min, and the molten material is discharged when it is cooled to 55°C;

[0040] Step 2: inject the cooled material into an injection molding machine for injection molding, and obtain PVC pipe fittings after cooling.

Embodiment 2

[0042] A preparation method for impact-resistant and toughened PVC pipe fittings, comprising the following steps:

[0043] SG~7 type PVC resin 100 parts

[0044] HL~60 type processing aid 4.9 parts

[0045] MBS~66 type impact modifier 5 parts

[0046] Calcium zinc heat stabilizer 6.9 parts

[0047] PCC~P type superfine calcium carbonate 13.8 parts

[0048] SR~240 type titanium dioxide 2.8 parts

[0049] DS~65 type dioctyl ester 4.9 parts

[0050] LA~W95 type lubricant 0.8 parts

[0051] Add the weighed raw materials into the high-speed mixer and stir. The temperature of the high-speed mixer is controlled at 115°C, the stirring time is 20min, and the molten material is discharged when it is cooled to 55°C;

[0052] Step 2: inject the cooled material into an injection molding machine for injection molding, and obtain PVC pipe fittings after cooling.

Embodiment 3

[0054] A preparation method for impact-resistant and toughened PVC pipe fittings, comprising the following steps:

[0055] SG~7 type PVC resin 100 parts

[0056] HL~60 type processing aid 4.5 parts

[0057] MBS~66 type impact modifier 3 parts

[0058] Calcium zinc heat stabilizer 6.5 parts

[0059] PCC~P type superfine calcium carbonate 12 parts

[0060] SR~240 type titanium dioxide 2.5 parts

[0061] DS~65 type dioctyl ester 4.6 parts

[0062] LA~W95 type lubricant 0.7 parts

[0063] Add the weighed raw materials into the high-speed mixer and stir. The temperature of the high-speed mixer is controlled at 115°C, the stirring time is 20min, and the molten material is discharged when it is cooled to 55°C;

[0064] Step 2: inject the cooled material into an injection molding machine for injection molding, and obtain PVC pipe fittings after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com