Piezoelectric film body wave resonator temperature sensor

A technology of temperature sensor and piezoelectric film, which is applied in the field of temperature sensing, can solve the problems of low sensitivity, low precision and high cost of thermistor temperature sensor, and achieve the effect of high sensitivity and good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

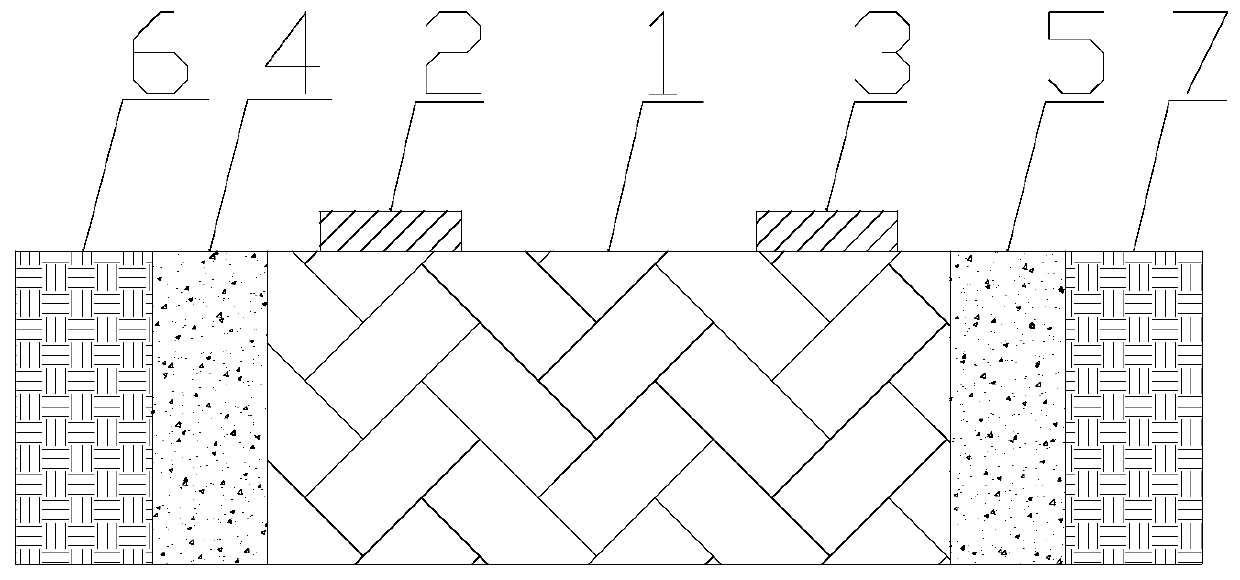

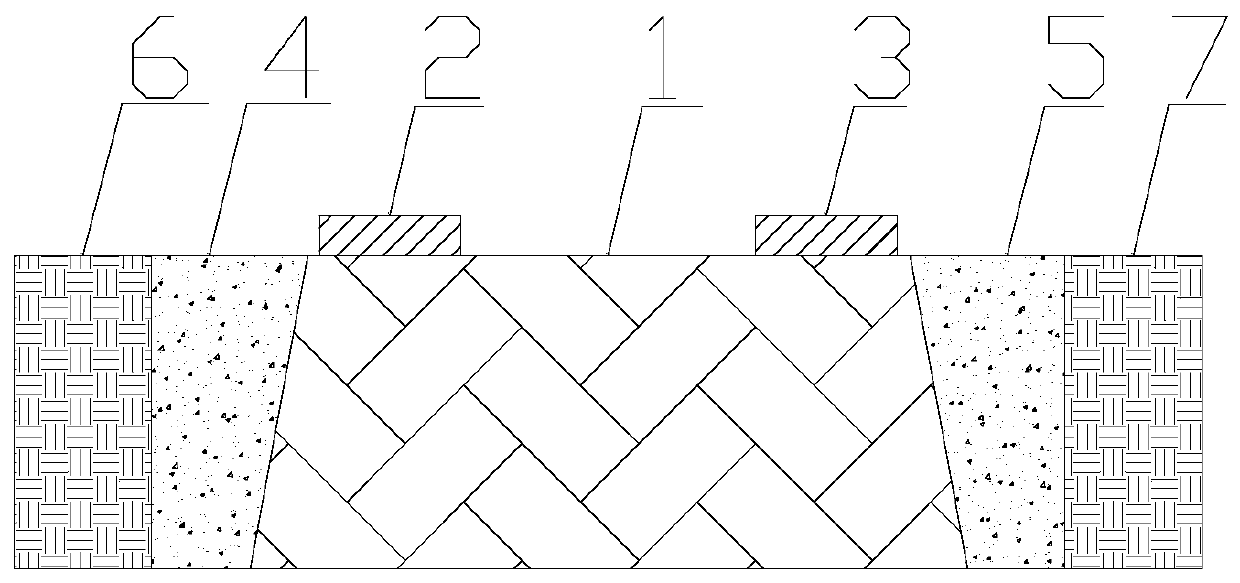

[0019] The invention provides a piezoelectric film bulk wave resonator temperature sensor, such as figure 1 As shown, the temperature sensor includes a piezoelectric body 1 , a first electrode 2 , a second electrode 3 , a first thermal expansion portion 4 , a second thermal expansion portion 5 , a first fixed portion 6 , and a second fixed portion 7 . The first electrode 2 and the second electrode 3 are arranged on the same side of the piezoelectric body 1 . In the present invention, the first electrode 2 and the second electrode 3 are arranged on the same side of the piezoelectric body 1, and the other side of the piezoelectric body 1 is exposed. This excitation method reduces the processing steps for preparing electrodes once, that is to say, no The electrodes are again prepared on the other side of the piezoelectric body 1, which reduces the cost. The first thermal expansion part 4 and the second thermal expansion part 5 are respectively arranged at both ends of the piezoe...

Embodiment 2

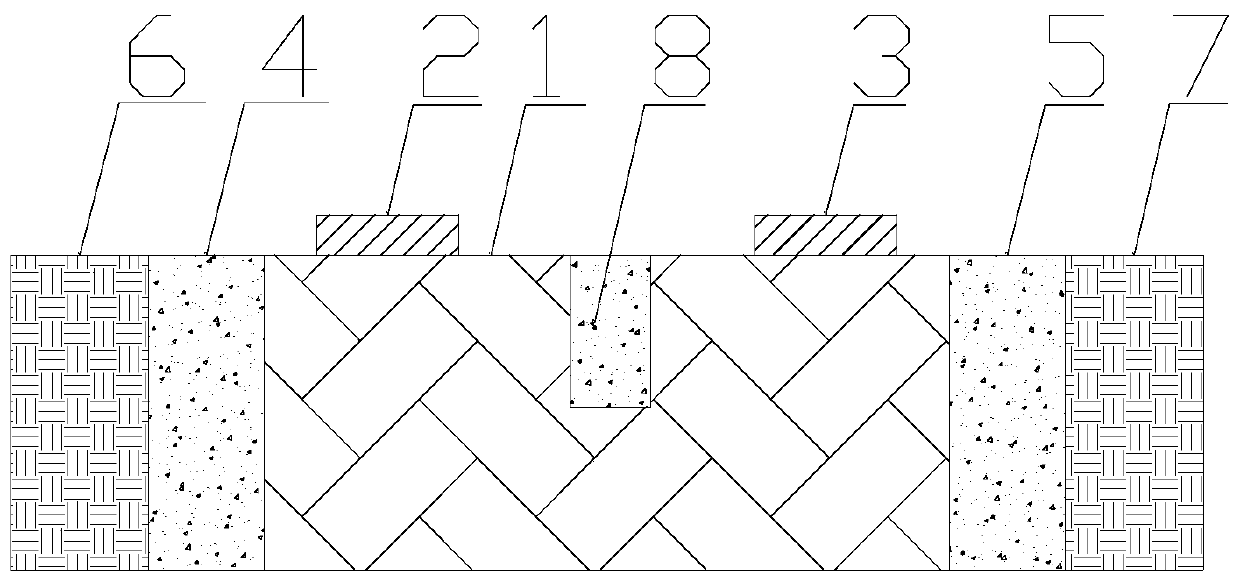

[0024] On the basis of Example 1, such as image 3 As shown, a groove 8 is provided between the first electrode 2 and the second electrode 3 and on the piezoelectric body 1 . The groove 8 does not penetrate the entire piezoelectric body 1 . The width of the groove 8 is less than half the resonance wavelength. In this way, when the first thermal expansion part 4 and the second thermal expansion part 5 expand, the extrusion force reduces the width of the groove 8, strengthens the wave coupling on the left and right sides of the groove 8, and changes the piezoelectric body 1 Resonance frequency. This embodiment reflects the influence of temperature on the resonance frequency of the piezoelectric body from the direction of the influence of the coupling on the resonance frequency of the piezoelectric body 1, and realizes the temperature sensing of the piezoelectric thin film bulk wave resonator with different mechanisms.

[0025] Furthermore, thermal expansion material is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com