Miniaturized multipath optical fiber rotary connector

A rotary connector and multi-channel optical fiber technology, which is applied in the field of optical signal transmission, can solve the problem that the multi-channel optical fiber rotary connector cannot meet the size and weight requirements, and is strict, and achieves the reduction of external size, weight, and outer diameter The effect of reduction and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred mechanism and motion realization method of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

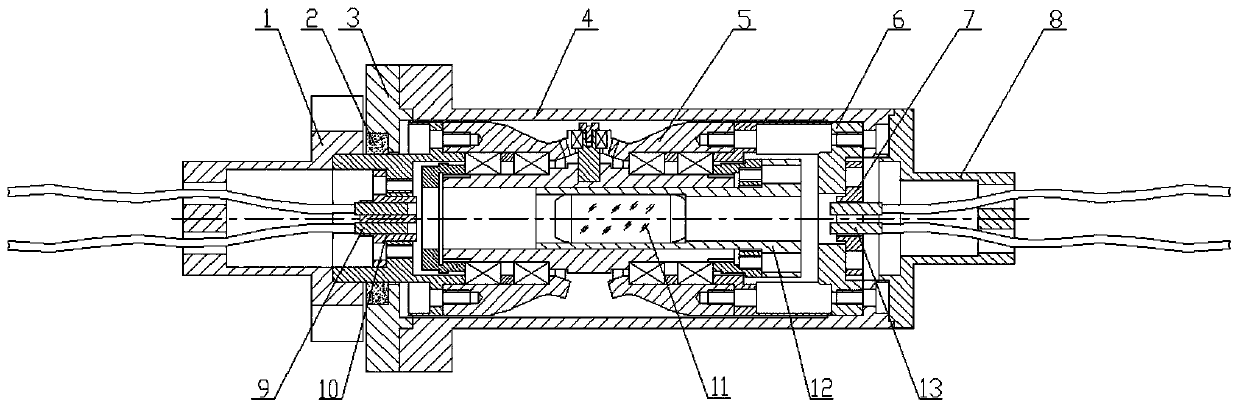

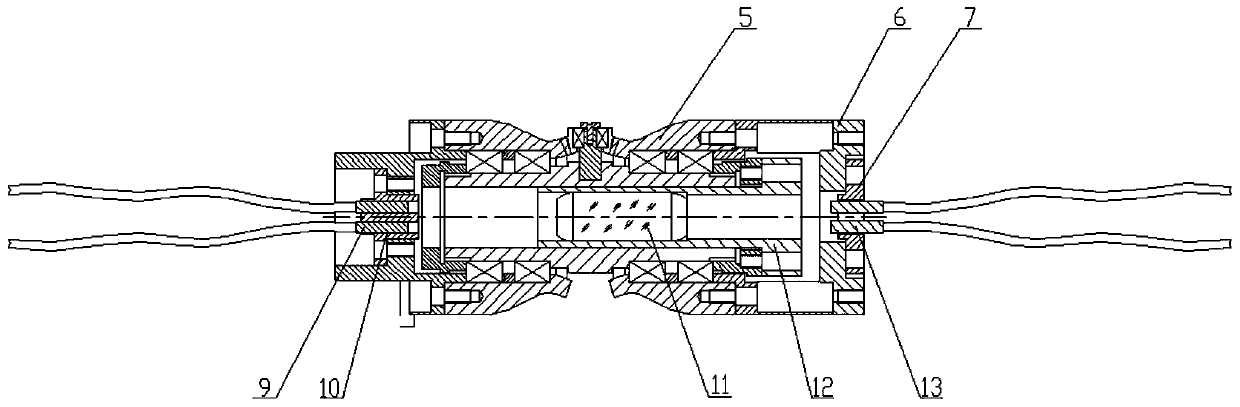

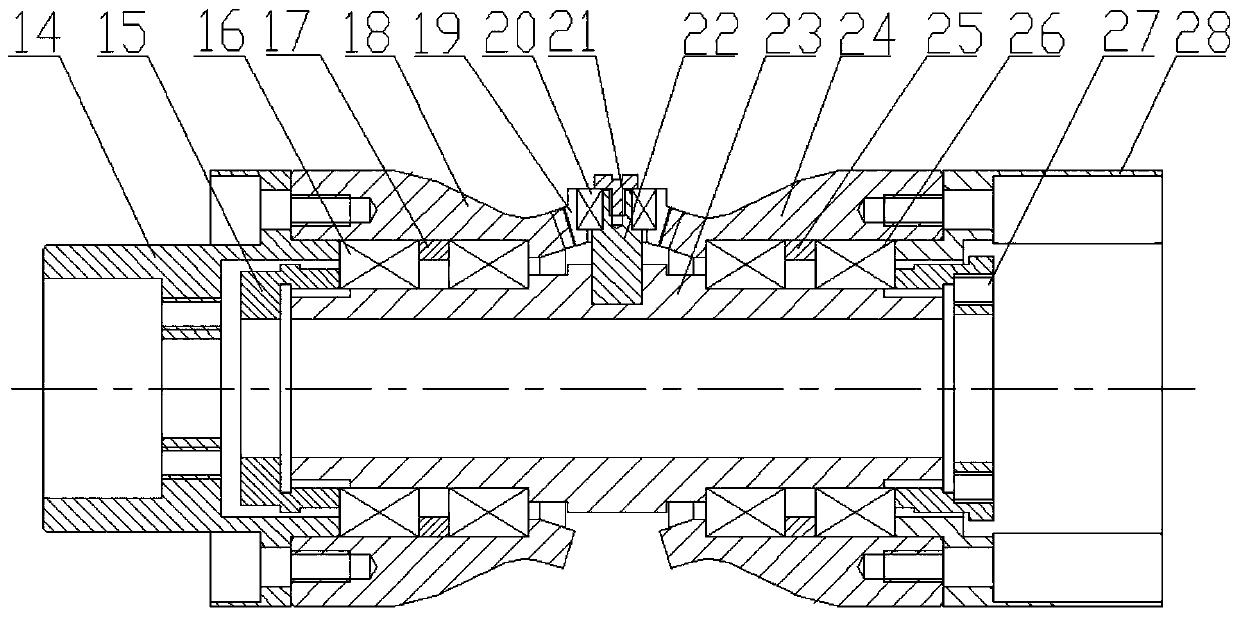

[0025] like Figure 1-3 As shown, a miniaturized multi-way optical fiber rotary connector includes a core and a detachable shell.

[0026] The core includes a rotating end outgoing line assembly, a fixed end outgoing line assembly, a transmission mechanism 5 and a prism assembly; the rotating end outgoing line assembly and the fixed end outgoing line assembly are respectively installed at both ends of the transmission mechanism 5, and the prism assembly is installed on The center of the transmission mechanism 5.

[0027] Among them, the rotating end outlet assembly is arranged on the left side of the core and installed on the left side of the transmission mechanism 5, including the moving end fiber collimator 9 and the moving end collimator fixed end cover 10; the moving end fiber collim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com