Silicon controlled rectifier module

A backplane and red copper technology, applied in the direction of semiconductor/solid-state device components, semiconductor devices, electrical components, etc., can solve the problems of shortened service life, high stress, easy to damage chips, etc., and achieve the effect of reducing stress and shortening service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

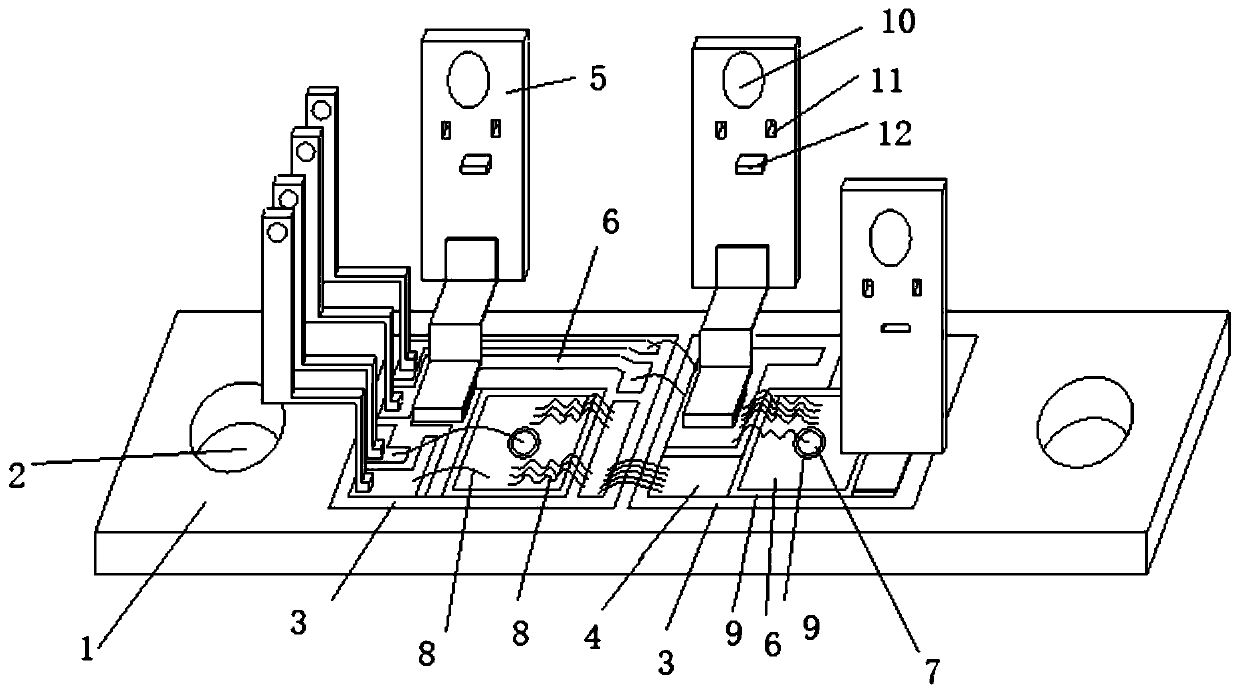

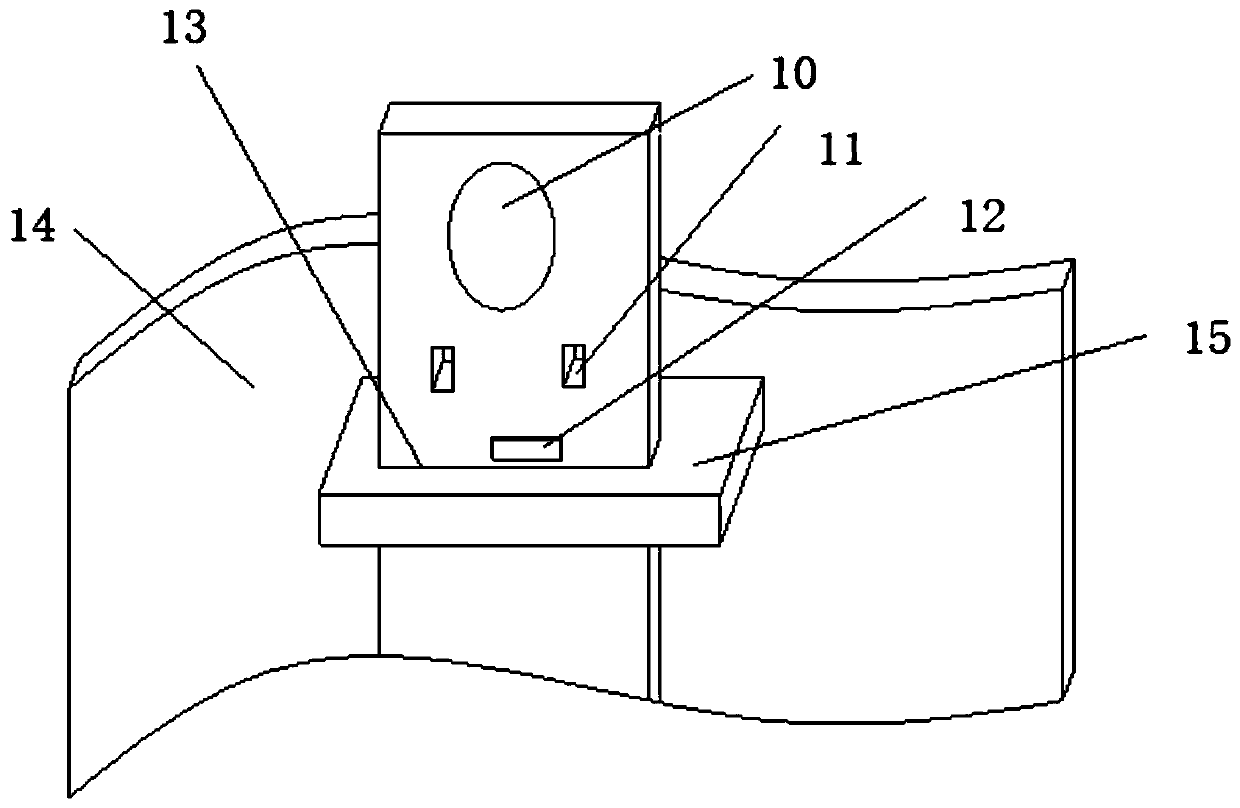

[0018] Examples such as figure 1 , figure 2 The silicon controlled rectifier module shown includes a copper base plate 1, a housing 14 arranged on the copper base plate 1, an external connection hole 2 is respectively provided at the left and right ends of the copper base plate 1, and the copper base plate 1 is located between the two external connection holes 2 Two ceramic sheets 3 are provided, and a set of copper-clad areas 4 are arranged on the two ceramic sheets 3 respectively. The copper-clad area 4 is provided with a set of lead-out electrode sheets 5 and two chips 6 according to the controllable rectification circuit, and the middle of the chip 6 is set There is a gate point 7, and an aluminum wire 8 is bonded between the chip 6 and the copper-clad area 4, and between the gate point 7 and the copper-clad area 4. The bonding of the aluminum wire 8 is realized by a wire punching machine.

[0019] In describing the present invention, it is to be understood that the ter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com