Integrated plug-in for motor, manufacturing method and motor

A manufacturing method, an integrated technology, applied in the direction of electrical components, electric components, manufacturing motor generators, etc., can solve the problems of difficult control of protection consistency, low compactness, poor product consistency, etc., to facilitate assembly and subsequent maintenance , plug-in connection is convenient, a complete range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

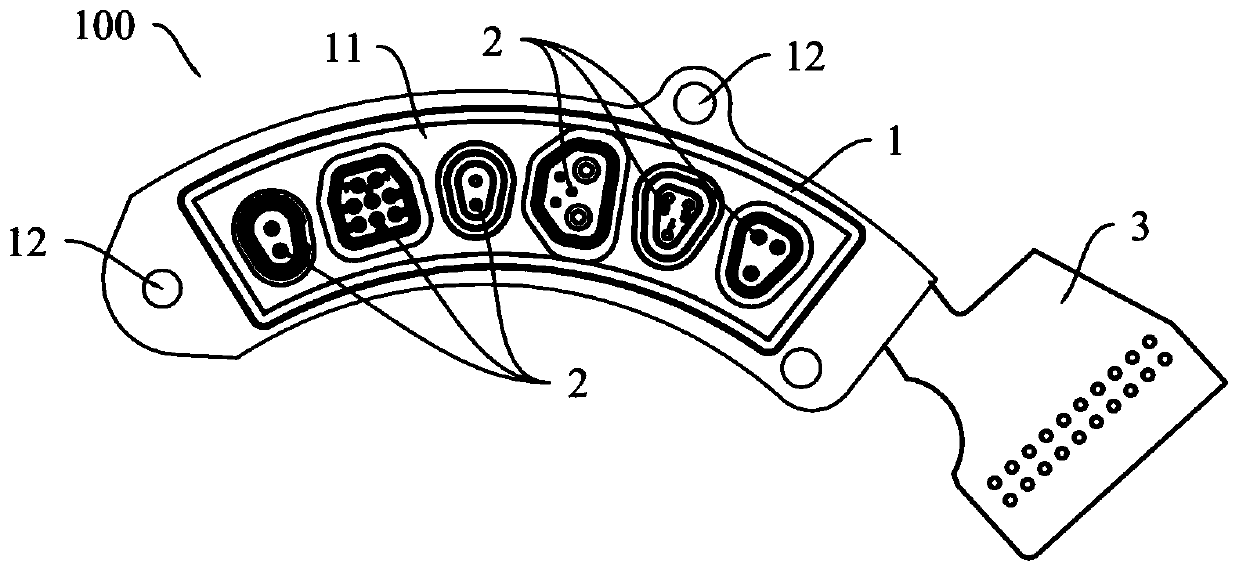

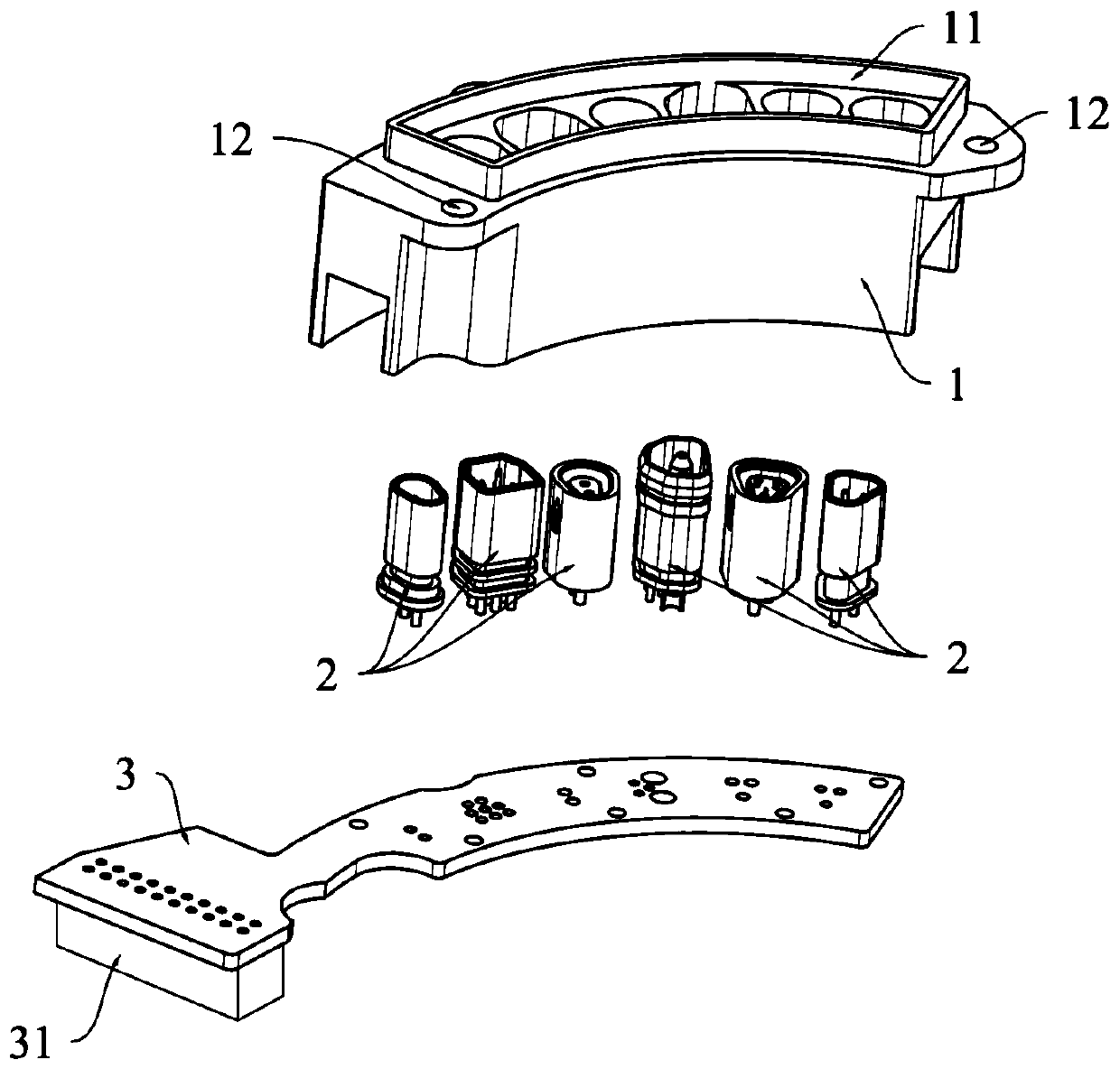

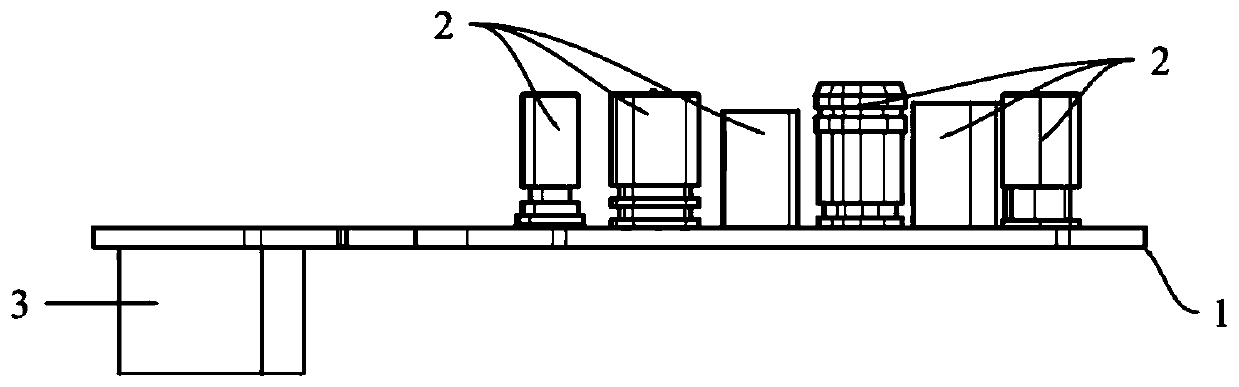

[0030] as attached figure 1 with attached figure 2 The one-piece plug-in 100 for the motor shown includes a plug-in base 1, a plurality of functional sockets and a PCB board 3; the main body of each functional socket 2 is embedded in the plug-in base 1, The front end of the functional socket 2 is a pluggable end of the external plug connector, the rear end of the functional socket 2 has pins, the front ends of each functional socket 2 are exposed, and the pins at the rear end of the functional socket 2 are fixed on the PCB. on board 3;

[0031] There are many kinds of the above-mentioned multiple functional sockets, and each functional socket 2 has a corresponding function. Some functional sockets 2 are used to transmit power, some functional sockets 2 are used to transmit signals, and some functional sockets 2 Power and signal can be transmitted at the same time. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com