Corn stalk cutting and crushing device

A technology of crushing device and corn stalk, applied in cutting equipment, agricultural machinery and implements, application, etc., can solve the problems of low efficiency and insufficient fiber density, and achieve the effect of easy separation and easy utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

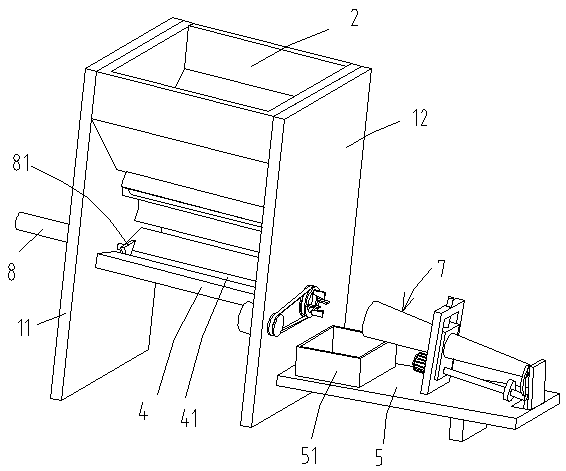

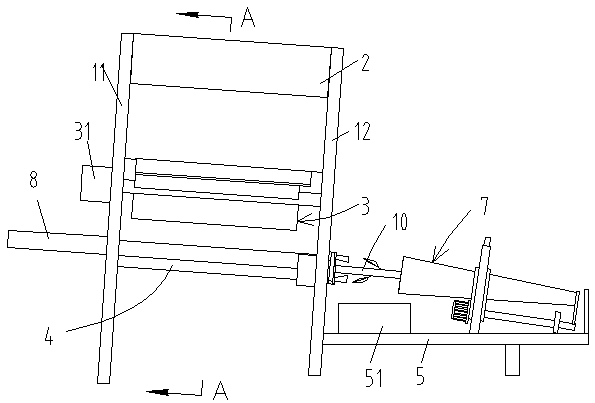

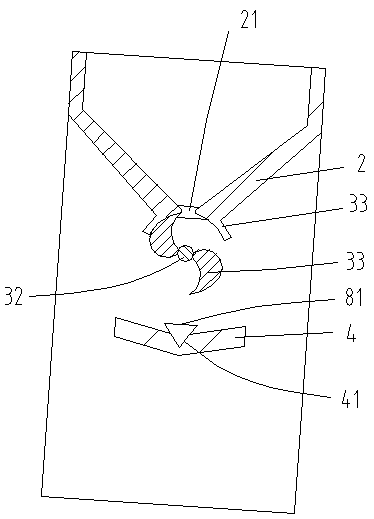

[0028] Such as Figure 1-5 As shown, a corn stalk cutting and crushing device provided by the present invention includes a first side plate 11 and a second side plate 12. The first side plate 11 and the second side plate 12 are fixedly connected to a storage box 2 and a storage box 2 The bottom of the storage box 2 is provided with a discharging trough 21. The inner cavity of the storage box 2 has a V-shaped bottom to facilitate the concentrated discharge of the straw 10 from the discharging trough 21. The bottom of the storage box 2 is provided with an intermittent discharging device 3, a first side plate 11 and a second side plate 11 The guide plate 4 is obliquely and fixedly connected between the side plates 12. The guide plate 4 is located directly below the storage box 2. The cross section of the guide plate 4 is V-shaped. The upper middle of the guide plate 4 is provided with a guide groove 41, and the guide groove 41 is directly opposite The center of the ring 6 is set. ...

Embodiment 2

[0036] As another embodiment of the pushing device of the present invention, such as Figure 6-10 As shown, the pushing device includes two clamping mechanisms with the same structure and staggered on the guide plate 4. The bottom of the guide plate 4 is symmetrically connected to two servo motors 91, and the main shaft of each servo motor 91 passes through the guide plate 4 The escape hole is fixedly connected to the swing plate 92 at the end. The opposite sides of the two swing plates 92 are respectively fixedly connected to a first semicircular plate 93. The outer circular surface of the first semicircular plate 93 is provided with a groove 931, and the groove 931 The support plate 932 is slidably connected to the support plate 932. The arc slide 933 is fixedly connected to the support plate 932. The side of the arc slide 933 away from the support plate 932 is provided with a non-slip groove. The support plate 932 is fixedly connected to the arc rod 934 and the groove 931. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com