Vacuum freeze drying method for non-heading Chinese cabbage named as yellow rose

A technology of vacuum freeze-drying and heading cabbage, which is applied in the agricultural field, can solve the problems of unfavorable storage and transportation, high water content, etc., and achieve the effects of reduced loss, fast instant solubility, good instant solubility and rehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

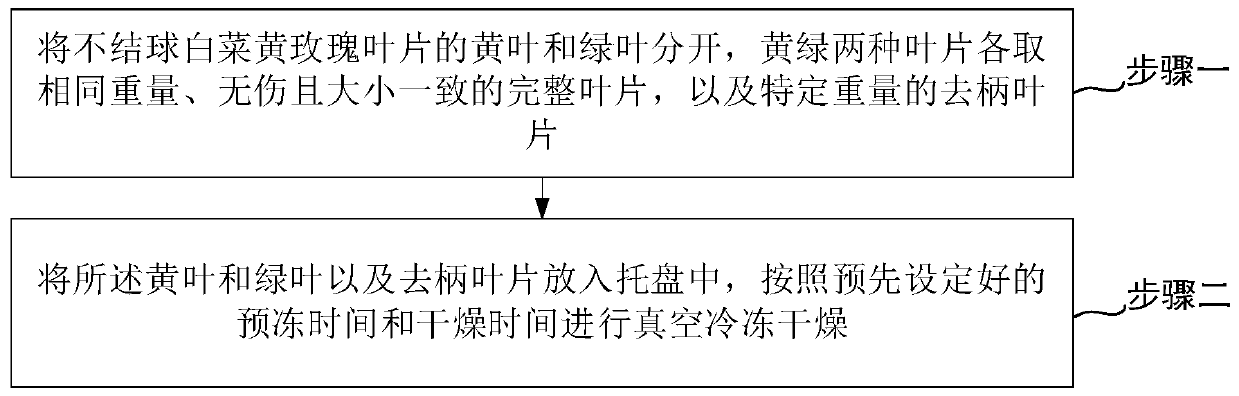

Method used

Image

Examples

Embodiment 1

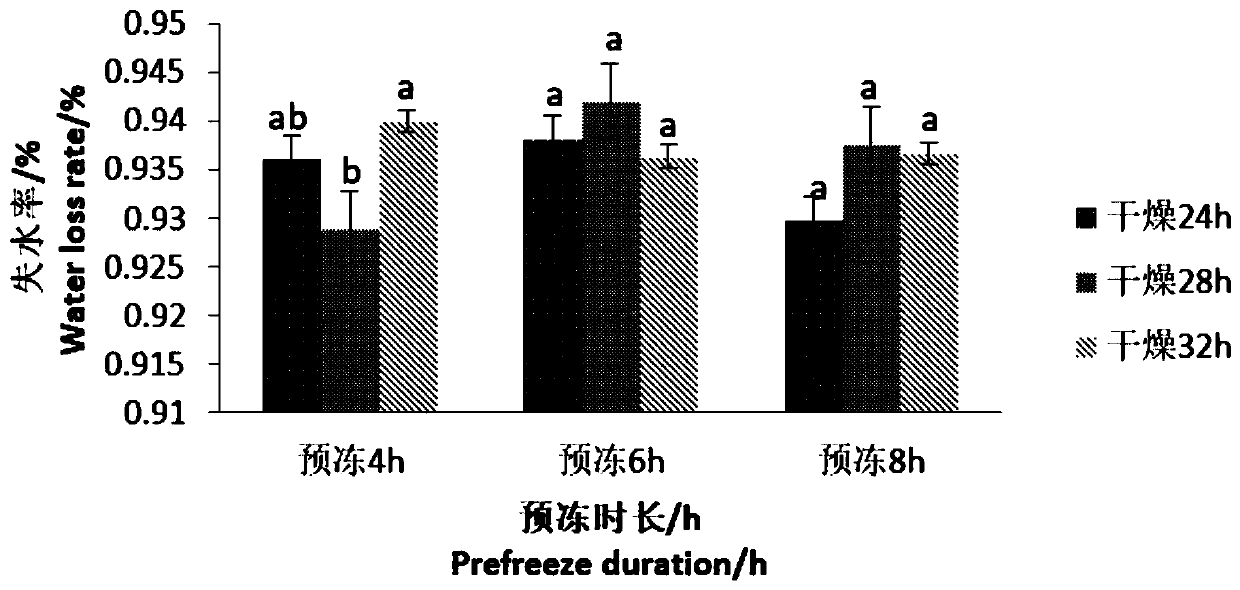

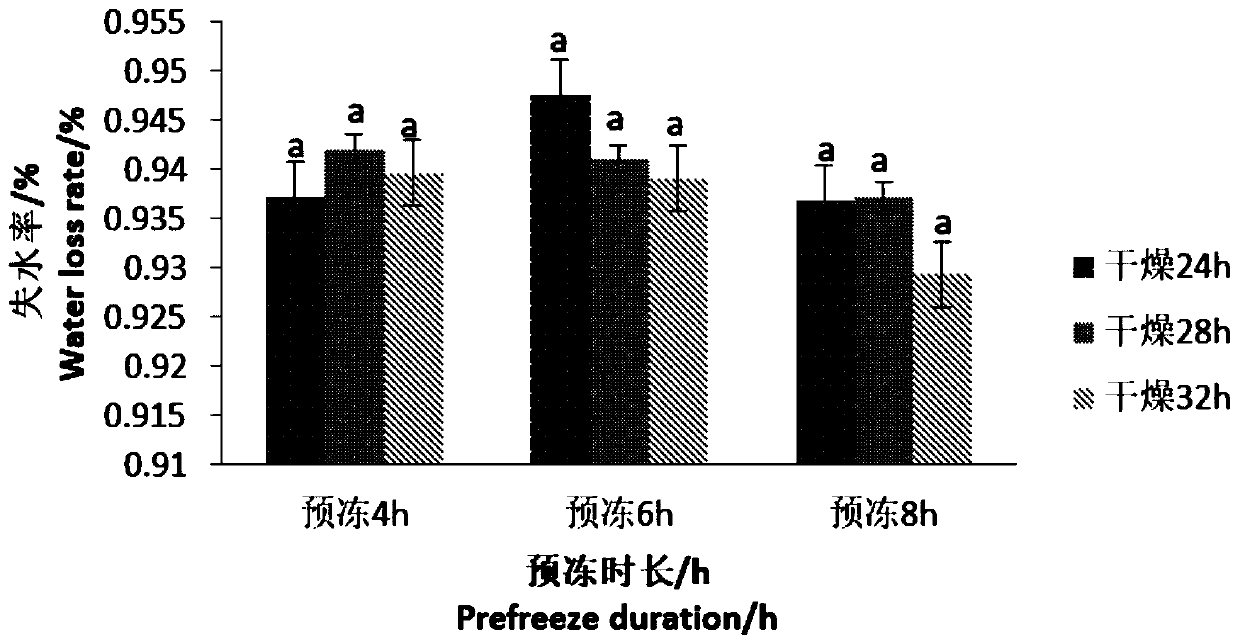

[0045] The improvement technology of freeze-dried non-heading cabbage yellow rose in this embodiment is to pre-freeze for 4 hours, and then vacuum-dry for 24 hours. Separate the yellow leaves and green leaves of the yellow rose leaves, and take about 200g of intact leaves and about 70g of unstalked leaves for each of the yellow and green leaves, and put them into a tray for vacuum freeze-drying according to a preset procedure.

Embodiment 2

[0047] The improvement technology of the freeze-dried non-heading Chinese cabbage Yellow Rose in this embodiment is to pre-freeze for 4 hours and then vacuum-dry for 28 hours. Separate the yellow leaves and green leaves of the yellow rose leaves, and take about 200g of intact leaves and about 70g of unstalked leaves for each of the yellow and green leaves, and put them into a tray for vacuum freeze-drying according to a preset procedure.

Embodiment 3

[0049] The improvement technology of freeze-dried non-heading cabbage yellow rose in this embodiment is to pre-freeze for 4 hours and vacuum dry for 32 hours. Separate the yellow leaves and green leaves of the yellow rose leaves, and take about 200g of intact leaves and about 70g of unstalked leaves for each of the yellow and green leaves, and put them into a tray for vacuum freeze-drying according to a preset procedure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com