Submersed nozzle for continuous casting

An immersion and nozzle technology, applied in casting equipment, casting melt containers, metal processing equipment, etc., can solve the problems of lowering the temperature of molten steel, not inhaling air, and not oxidizing, so as to avoid secondary oxidation and improve quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

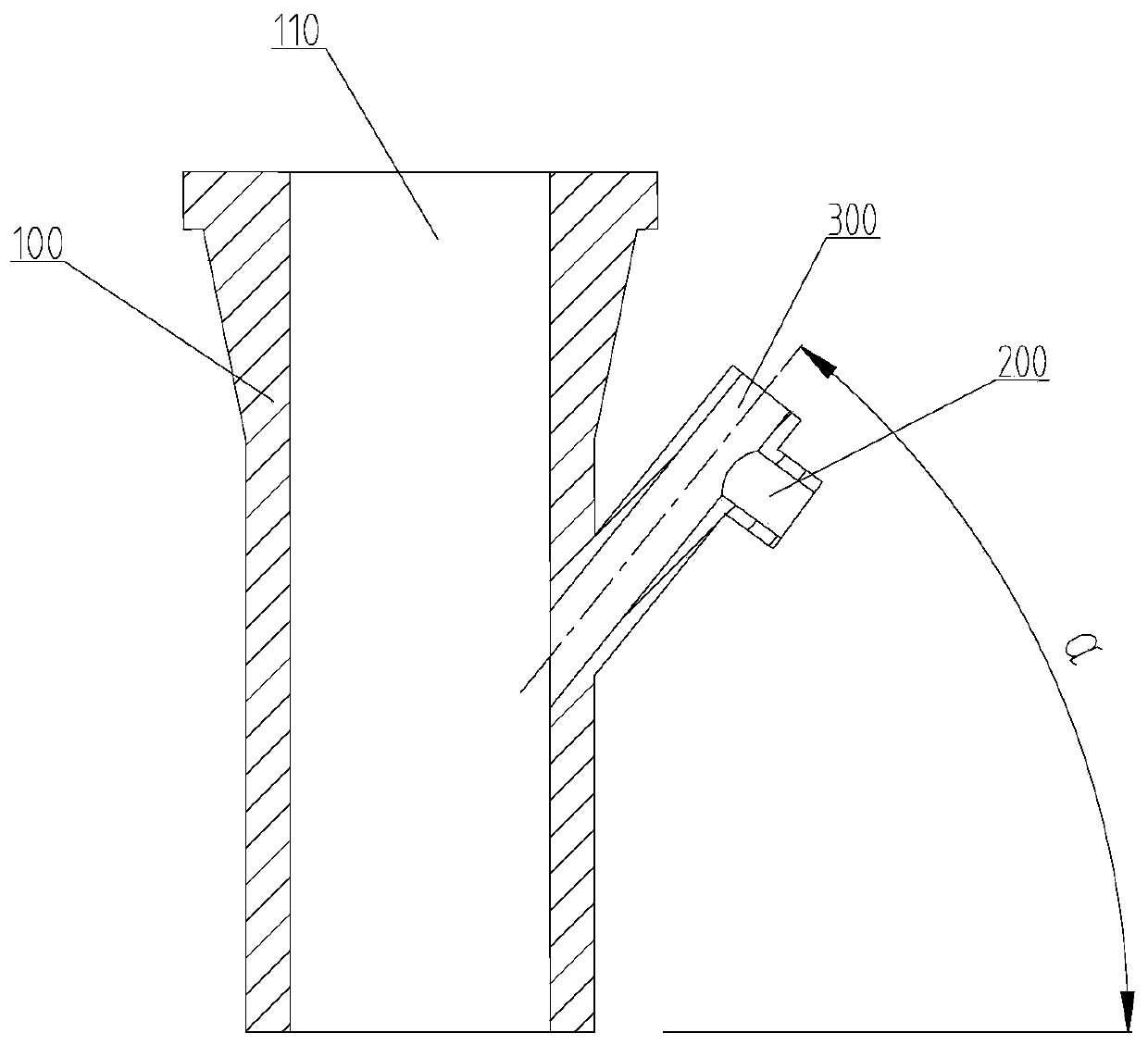

[0023] A submerged nozzle for continuous casting, including a nozzle body 100, a side arm pipe 200 and a gas pipe 300. The nozzle body 100 is a hollow straight cylinder structure, and the inside of the nozzle body 100 is a nozzle inner cavity 110; the side arm pipe 200 is inclined upward It is arranged on the main body of the nozzle 100 and communicates with the inner cavity 110 of the nozzle. The angle between the center line of the side arm pipe 200 and the horizontal line is 61°, the length of the side arm pipe 200 is 5mm, and the diameter of the side arm pipe 200 is equal to the inner diameter of the nozzle. The inner diameter of the cavity 110; the gas pipeline 300 communicating with the side arm pipeline 200 is provided under the side arm pipeline 200, and a high temperature resistant metal gas valve is provided at the inlet of the gas pipeline 300.

[0024] During the continuous casting production process, the submerged nozzle used for continuous casting is connected to ...

Embodiment 2

[0026] A submerged nozzle for continuous casting, including a nozzle body 100, a side arm pipe 200 and a gas pipe 300, the nozzle body 100 is a hollow straight cylinder structure, the interior of the nozzle body 100 is a nozzle inner cavity 110; the side arm pipe 200 is inclined upward It is arranged on the main body of the nozzle 100 and communicates with the inner cavity 110 of the nozzle. The angle between the center line of the side arm pipe 200 and the horizontal line is 90°, the length of the side arm pipe 200 is 50mm, and the diameter of the side arm pipe 200 is equal to One-half of the inner diameter of the cavity 110; a gas pipeline 300 communicating with the side arm pipeline 200 is provided below the side arm pipeline 200, and a high temperature resistant metal gas valve is provided at the entrance of the gas pipeline 300.

[0027] During the continuous casting production process, the submerged nozzle used for continuous casting is connected to the continuous casting...

Embodiment 3

[0029] A submerged nozzle for continuous casting, including a nozzle body 100, a side arm pipe 200 and a gas pipe 300, the nozzle body 100 is a hollow straight cylinder structure, the interior of the nozzle body 100 is a nozzle inner cavity 110; the side arm pipe 200 is inclined upward Set on the main body of the nozzle 100 and communicate with the inner cavity 110 of the nozzle, the angle between the center line of the side arm pipe 200 and the horizontal line is 75°, the length of the side arm pipe 200 is 30mm, and the diameter of the side arm pipe 200 is equal to the inner diameter of the nozzle. Two-thirds of the inner diameter of the cavity 110; a gas pipeline 300 communicating with the side arm pipeline 200 is provided below the side arm pipeline 200, and a high temperature resistant metal gas valve is provided at the entrance of the gas pipeline 300.

[0030] During the continuous casting production process, the submerged nozzle used for continuous casting is connected t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com