Tire rubber linkage cutting and recovering device based on environment-friendly processing

A recycling device and tire technology, applied in plastic recycling, recycling technology, mechanical material recycling, etc., can solve problems such as jamming, inability to classify and cut, and manual support for safety hazards, and achieve the effect of ensuring smoothness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

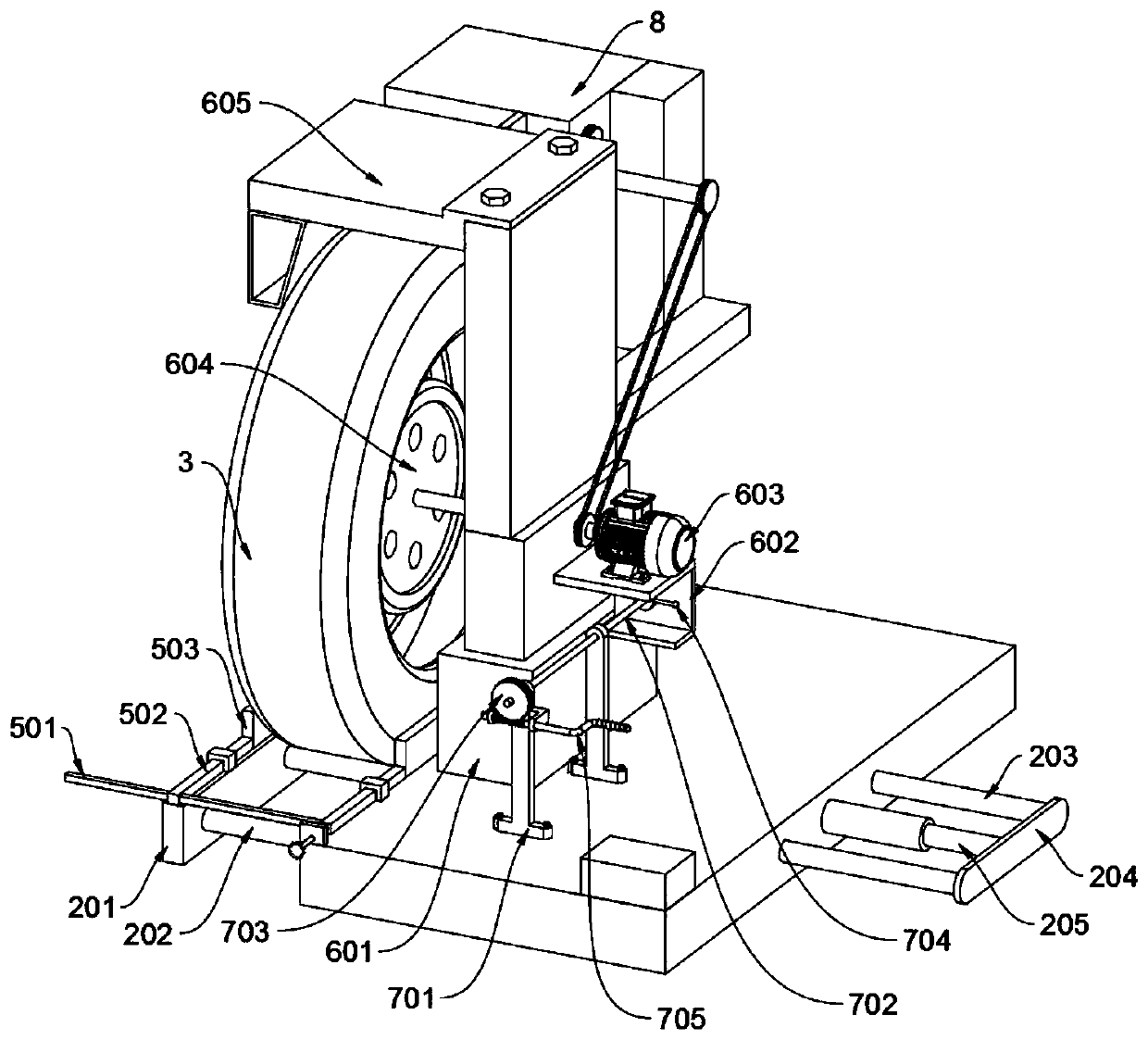

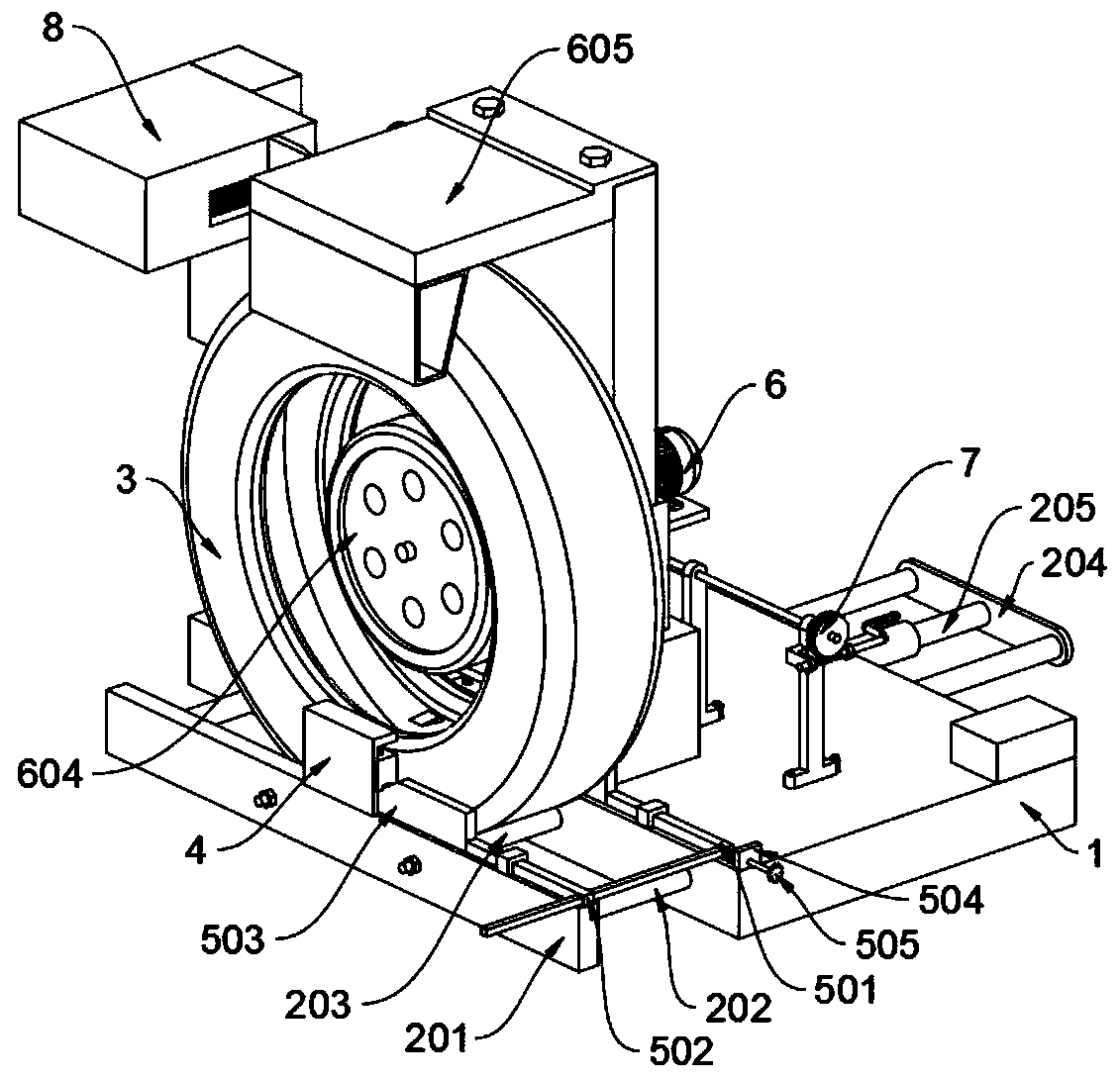

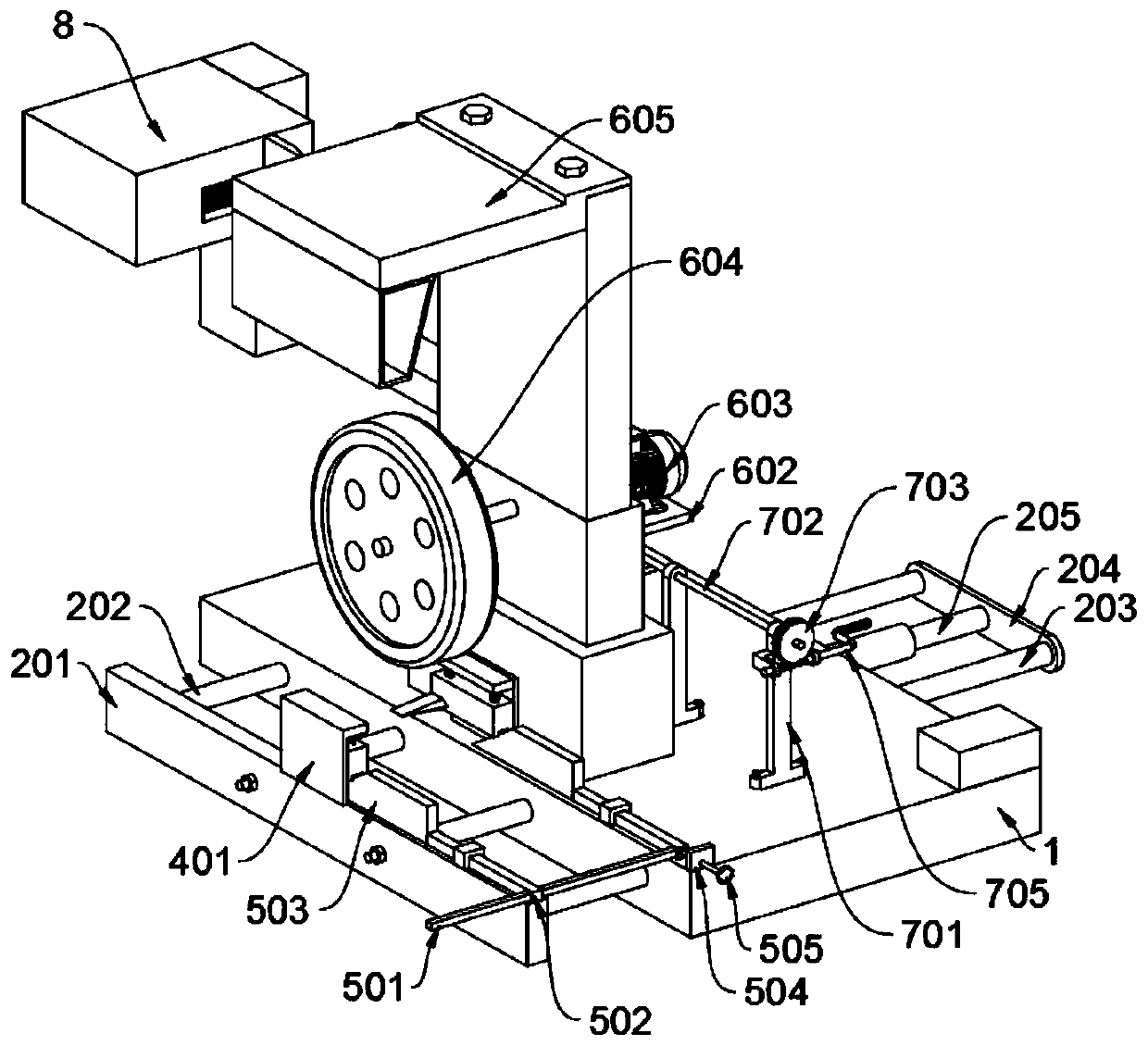

[0033] as attached figure 1 To attach Figure 8 Shown:

[0034] The invention provides a tire rubber linkage removal and recovery device based on environmental protection processing, which includes a base 1; a fixed structure 2 is installed on the base 1, and a tire 3 is placed on the fixed structure 2; a The cutter structure 4, and the two cutter structures 4 are symmetrical, and a first adjustment structure 5 is also installed on the base 1; refer to as Figure 5 , the first adjustment structure 5 includes a first adjustment frame 501 and a second adjustment frame 502, the first adjustment frame 501 is slidably connected to the base 1 through a sliding connection seat, and the second adjustment frame 502 is slidably connected to the splint 201 through a sliding connection seat Above; the first adjustment frame 501 and the second adjustment frame 502 are connected together, and the first adjustment frame 501 and the second adjustment frame 502 together form an adjustable st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com