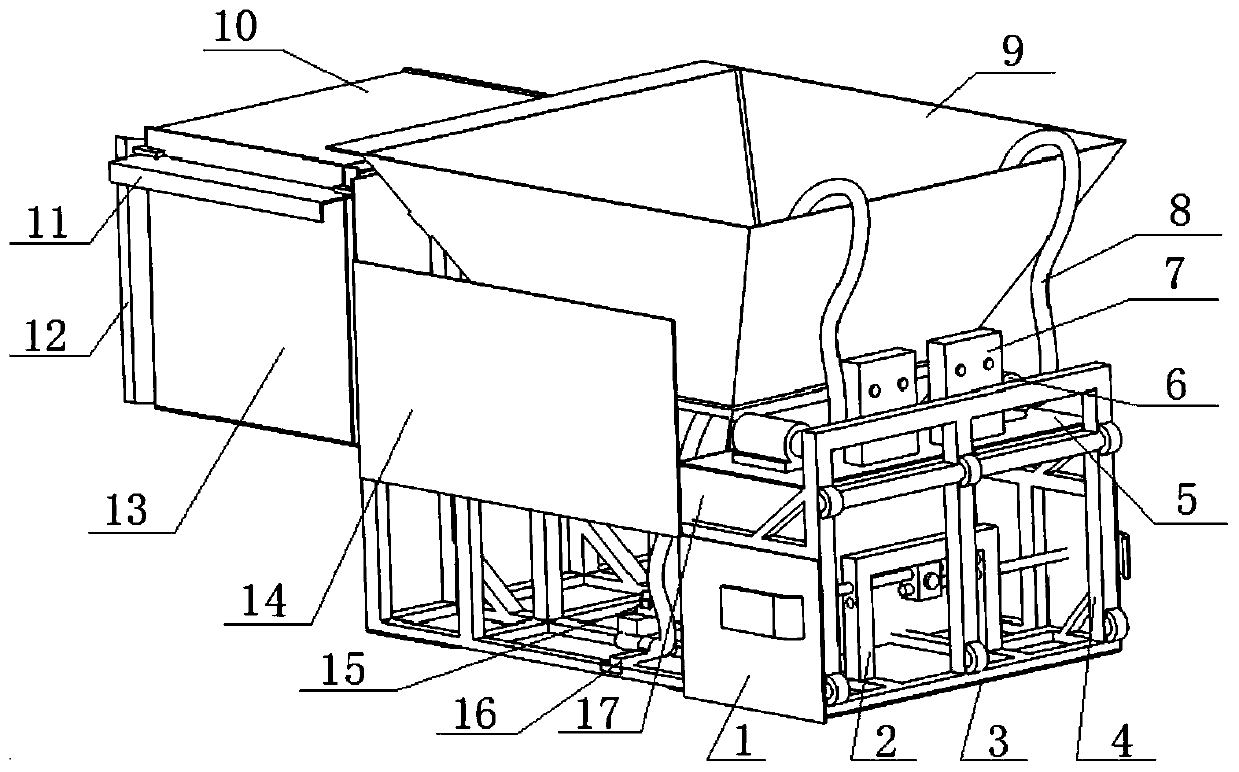

Highway drainage ditch traction extrusion type slip form construction equipment and construction method

A technology of construction equipment and drainage ditches, which is applied in the field of construction equipment for one-time slip-form molding of highway drainage ditches, can solve the problems of affecting construction quality, increasing construction costs, and inability to flexibly adjust the style and size of drainage ditches, so as to improve construction progress and Construction quality, reduced ditch construction cost, and high practical value of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

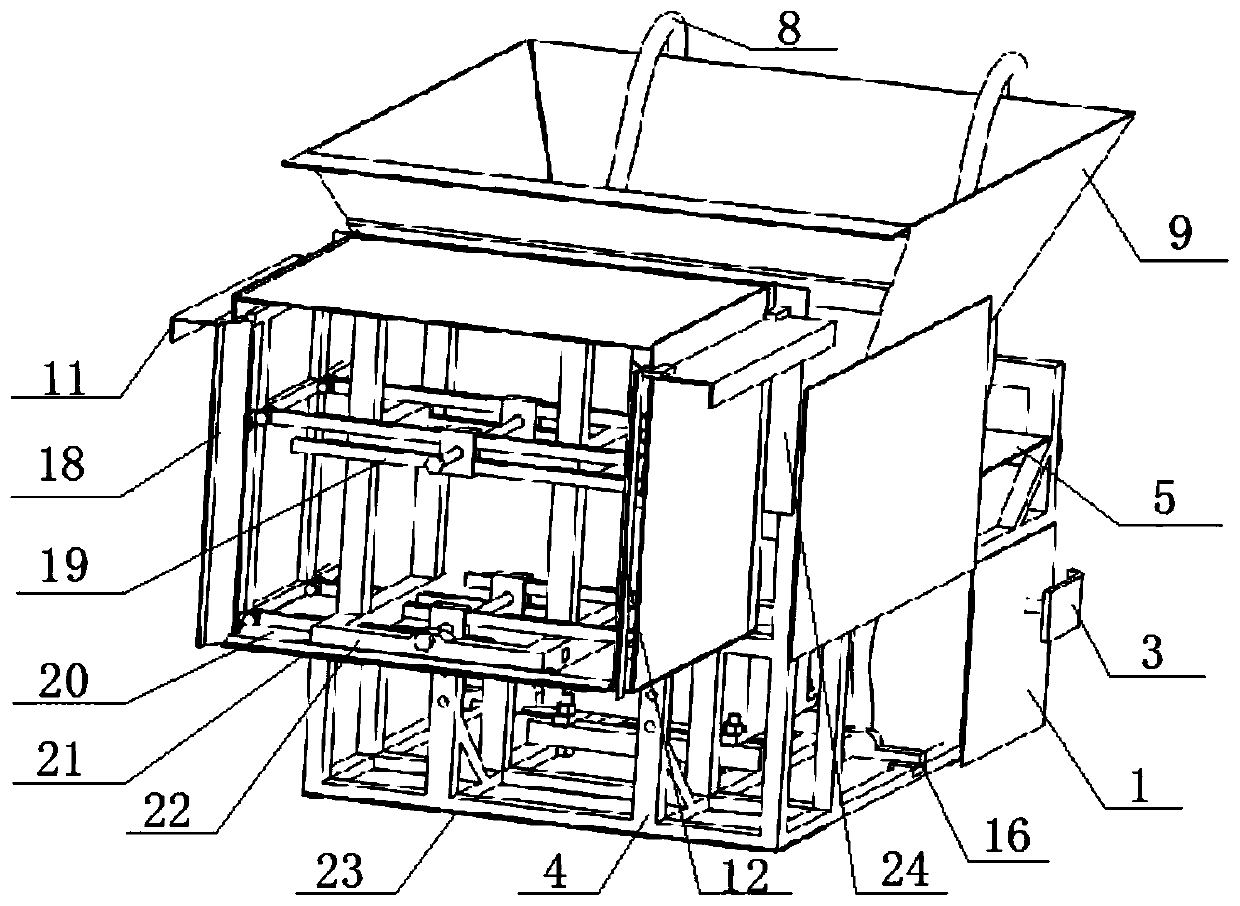

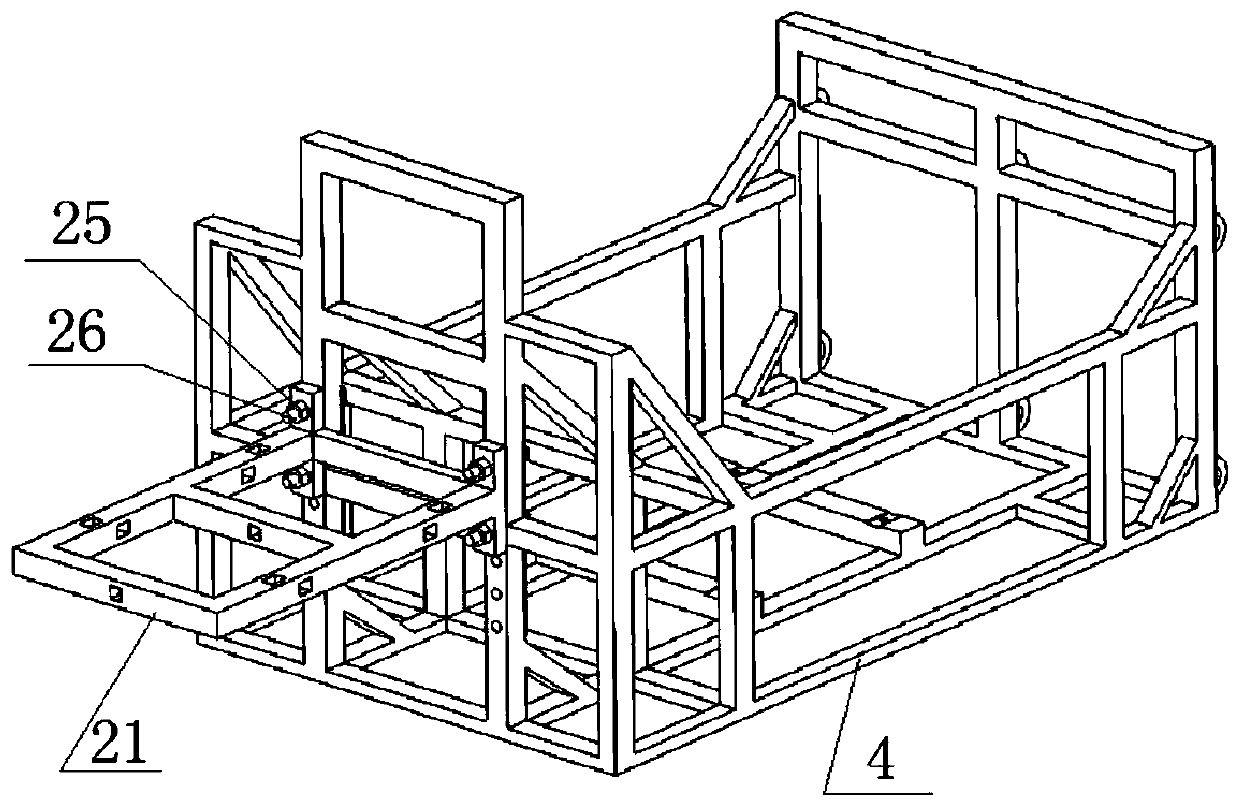

[0053] The construction equipment and construction method of traction extrusion type slip form for highway drainage ditches mainly include the following steps:

[0054] Place the construction equipment in the adobe ditch of the drainage ditch, adjust the bottom width of the formwork section adjustment device to 500mm, adjust the angle between the left and right frames and the vertical direction to 0°, and adjust the distance between the slipform top plate and the slipform bottom plate to 600mm.

[0055] Pour the concrete with a slump of 30mm into the construction equipment hopper, the winch pulls the construction equipment forward at a speed of 1.0m / min, set the vibration frequency of the vibrating bar to 40Hz, the amplitude to 2mm, and the vibration time to 20s, and start the drainage ditch traction and extrusion During the construction operation of the sliding formwork, concrete materials are added in time according to the storage conditions of the hopper during the construct...

Embodiment 2

[0060] The construction equipment and construction method of traction extrusion type slip form for highway drainage ditches mainly include the following steps:

[0061] Place the construction equipment in the adobe ditch of the drainage ditch, adjust the bottom width of the formwork section adjustment device to 650mm, adjust the angle between the left and right frames and the vertical direction to 10°, and adjust the distance between the slipform top plate and the slipform bottom plate to 700mm.

[0062]Pour concrete with a slump of 45mm into the construction equipment hopper, and the winch pulls the construction equipment forward at a speed of 0.8m / min. Set the vibration frequency of the vibrating bar to 50Hz, the amplitude to 2mm, and the vibration time to 25s. During the construction operation of the sliding formwork, concrete materials are added in time according to the storage conditions of the hopper during the construction process, and the construction of the drainage di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com