Cable bent tower operating platform formwork separating and lifting system

A technology for separating operating platforms and templates, which is applied to lifting devices, erecting/assembling bridges, bridges, etc., can solve problems such as small safety factor, slow construction progress, poor wind resistance, etc., and achieve the effect of reducing expenditure and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

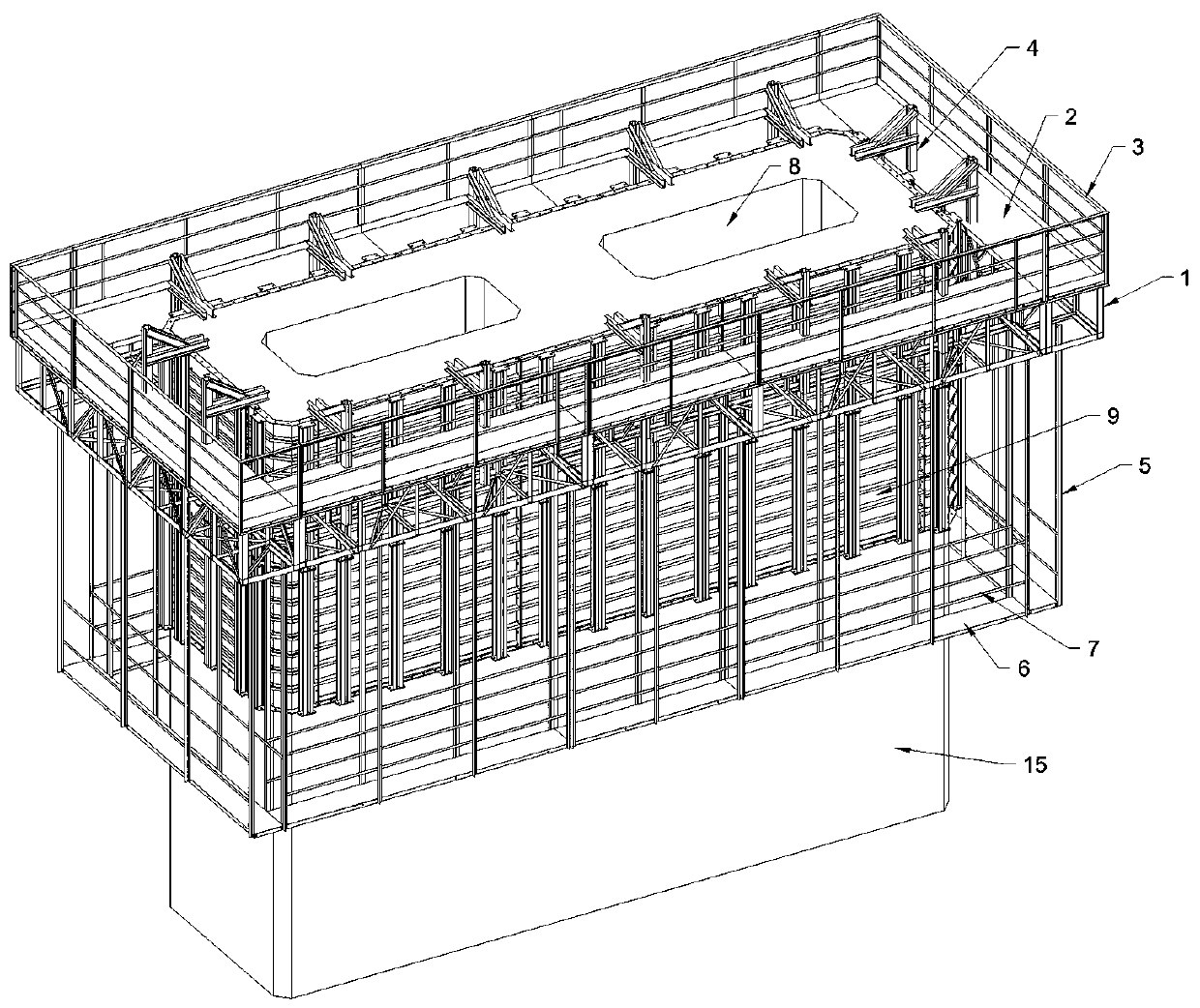

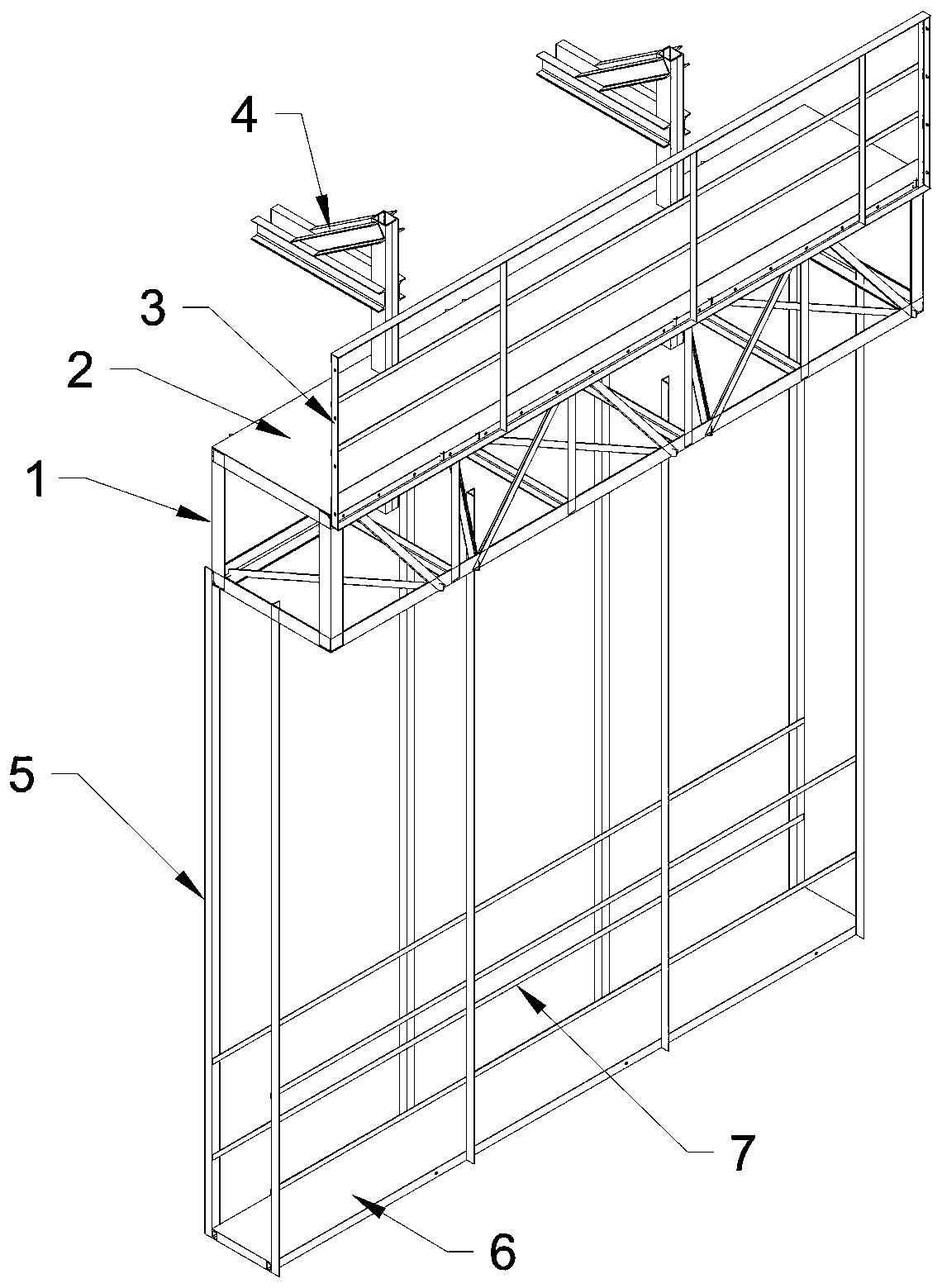

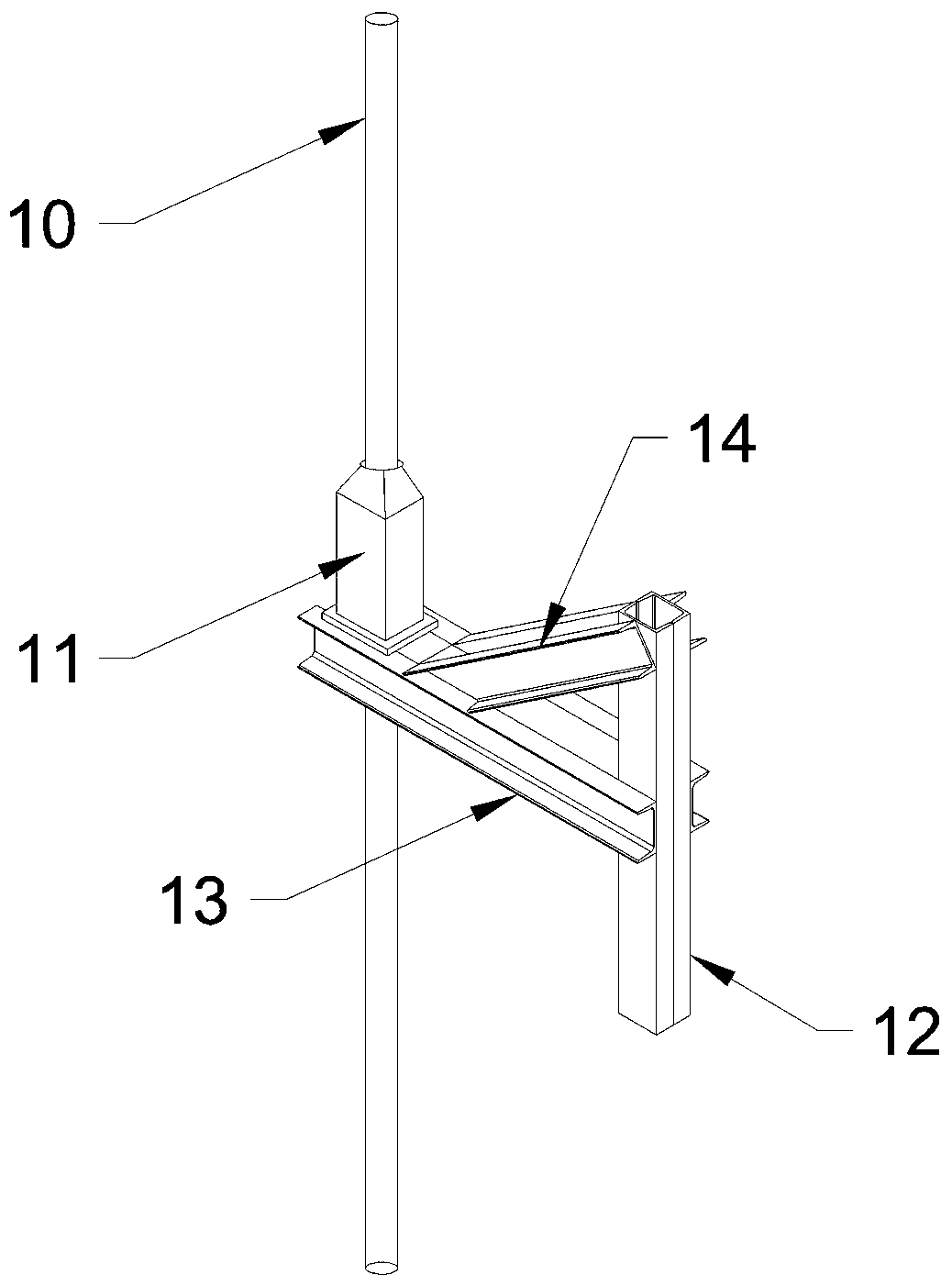

[0017] Such as Figure 1-3 As shown, the application provides a formwork separation and lifting system for a cable tower operation platform, including a formwork system, a support system and a protection system. Among them, the formwork system includes an inner mold 8 and an outer mold 9, and the inner mold 8 and the outer mold 9 are fixedly connected by a pair of pull screws; the support system includes an enclosure 1, a lifting frame 4 and a support rod 10, and the support rod 10 is fixed on the concrete 15 Inside, the lifting frame 4 is fixed on the enclosure 1, and the enclosure 1 is sleeved on the outside of the outer mold 9. The lifting frame 4 is provided with a through-hole jack 11, and the through-hole jack 11 is connected to the support rod 10 by transmission. The outer mold 9 Hanging on the lifting frame 4; the protection system includes an operating platform 6 and a guardrail 7, the operating platform 6 is hung below the enclosure 1, and the guardrail 7 is fixed ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com