Wired network transmission underground electric shoveling and conveying machine

An electric scraper and wired network technology, which is applied to mechanically driven excavators/dredgers, etc., can solve the problems of high safety hazards for personnel maintenance, many curved roadways, and small cross-section of underground roadways, so as to improve operation efficiency and work efficiency. security, solve network signal transmission, and improve the effect of application scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0020] The specific embodiment: the specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

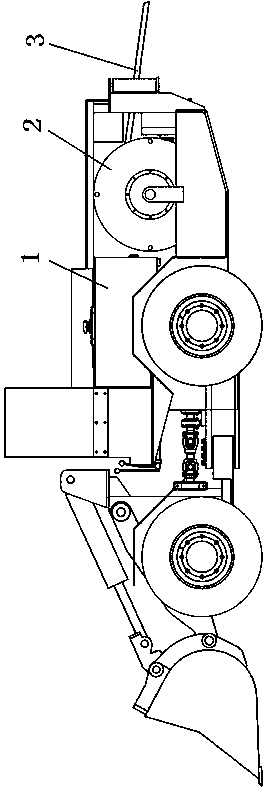

[0021] like figure 1 As shown, a wired network transmission underground electric scraper includes an electric scraper 1, a cable drum 2 is arranged on the electric scraper 1, and a mining cable 3 is wound on the cable drum 2. Electrical components such as motors in the electric scraper 1 transmit electric energy and signal transmission through the mining cable 3, and the cable drum 2 can automatically realize the retraction and retraction of the cable as the electric scraper 1 advances and retreats.

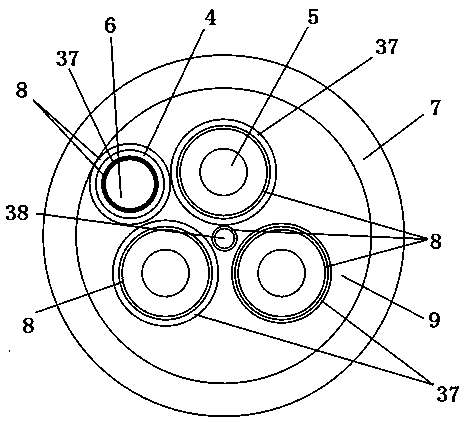

[0022] like figure 2 As shown, the mining cable 3 includes a rubber outer sheath 7, and the rubber outer sheath 7 is provided with three conductive cores 5, one gigabit network cable 6, and one tensile steel wire 38. Both the conductive core 5 and the tensile steel wire 38 are coated with an insulating layer 8, wherein the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com