Connecting mechanism for aerated concrete wall plate and method

A kind of technology of air-entrained concrete and connection mechanism, which is applied in the direction of walls, building components, building structures, etc. It can solve the problems of prolonging the construction period of houses and reducing the construction efficiency of wall panel hanging structures, so as to speed up construction efficiency and shorten construction period , to facilitate the effect of later maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions in the embodiments of the present invention will be further described below in conjunction with the drawings in the embodiments of the present invention.

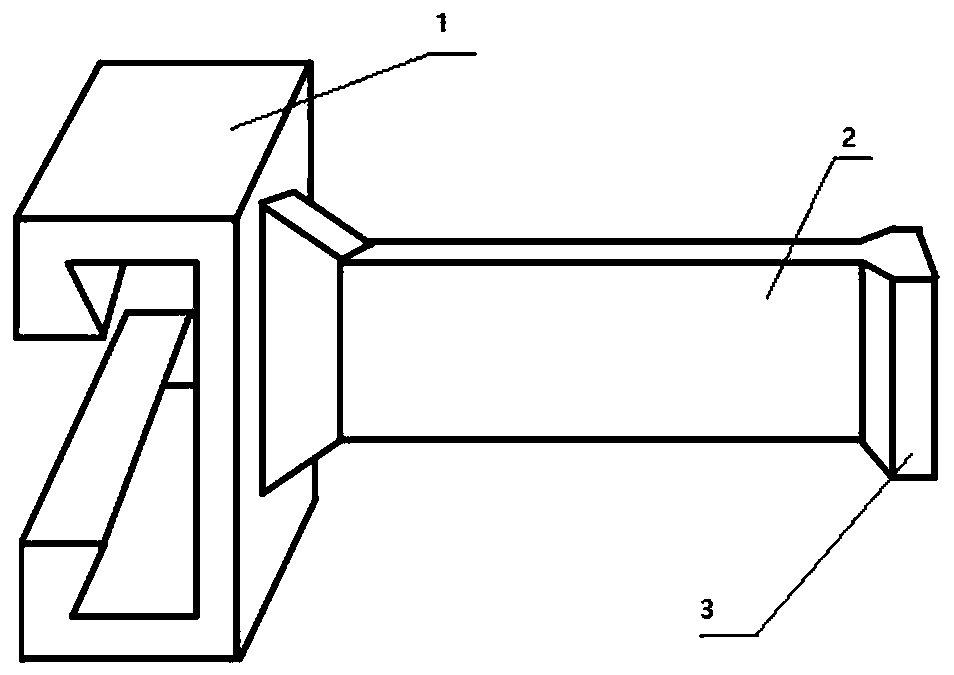

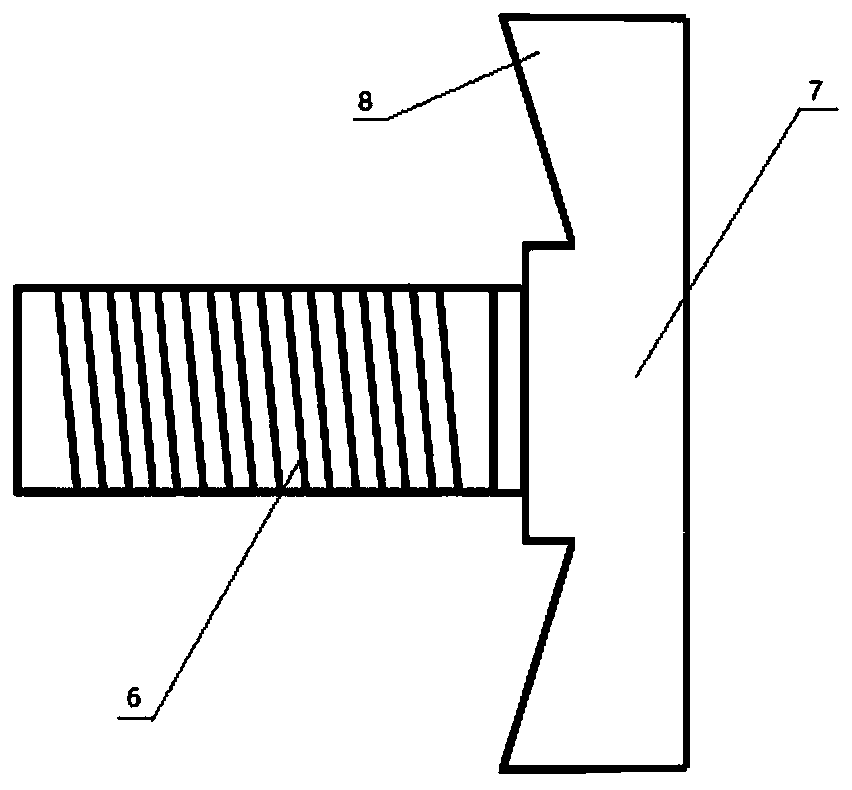

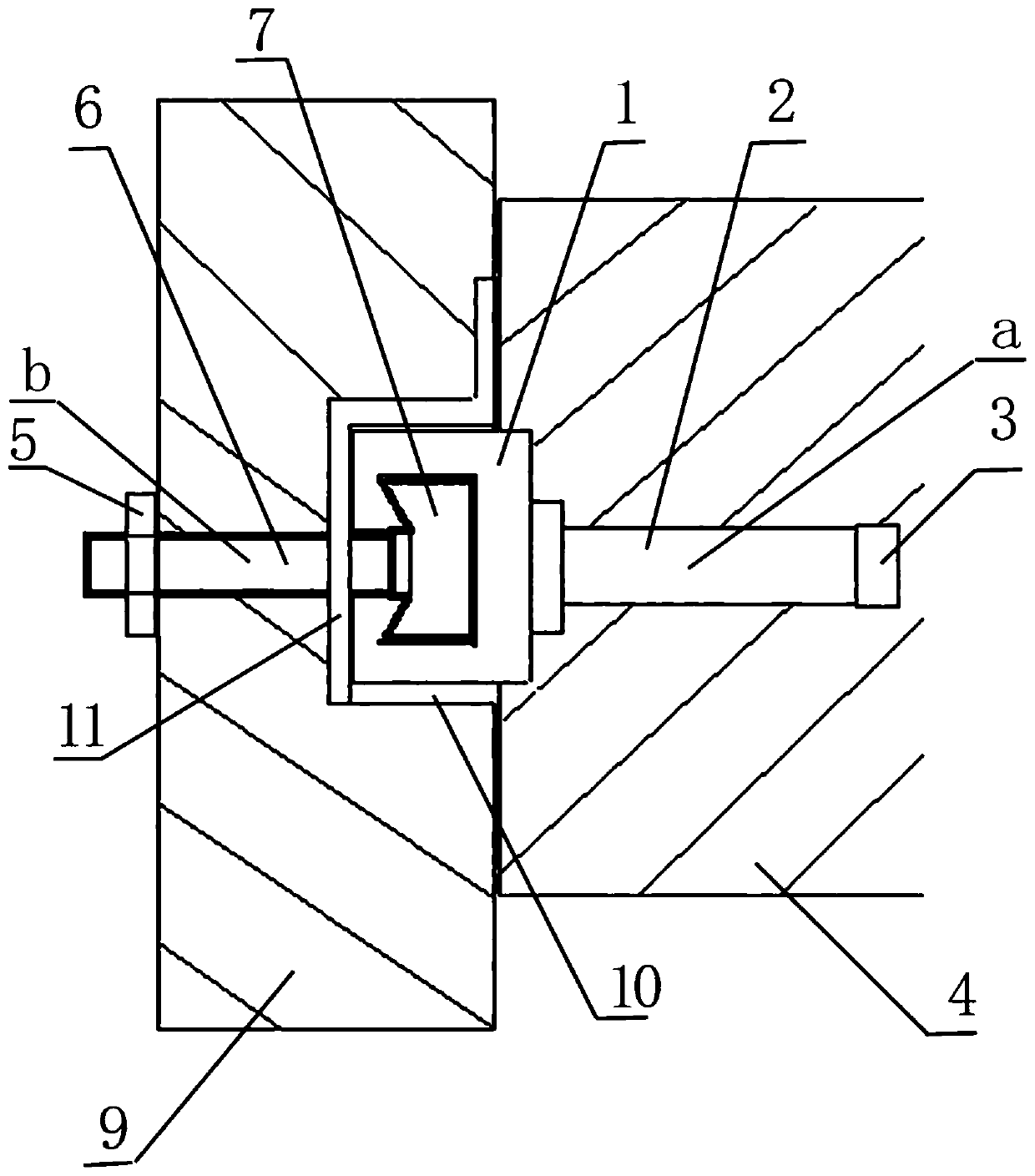

[0024] like figure 1 and figure 2 As shown, the aerated concrete wall panel connection mechanism of the present invention includes embedded parts a embedded in the steel beams on both sides of the building frame and buckles b in the wall panels matching the building frame, wherein the pre-embedded The embedded part a includes two parts, the head and the tail, wherein the head is a groove body 1 with a concave structure, the tail is a metal body 3 with a rhombus structure, a metal handle 2 is provided between the head and the tail, and the metal body 3 and the metal Both parts of the handle 2 are embedded in the concrete steel beam, which is integrated with the steel beam 4 of the building body. The buckle b is a bolt structure, and the buckle b includes a nut 5, a screw rod 6 and a bolt head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com