A Model Stage Performance Calculation Method for Low Pressure Ratio Axial Flow Compressor

A technology of axial flow compressor and low pressure ratio, applied in the field of axial flow compressor, can solve the problems of large test error, interference model-level internal flow field, large temperature measurement error, etc., and achieve the effect of improving the research level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

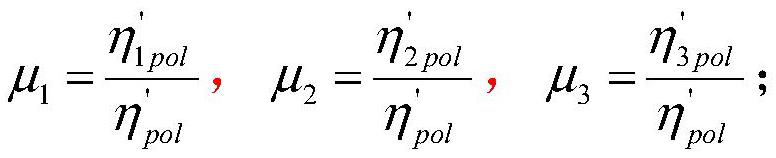

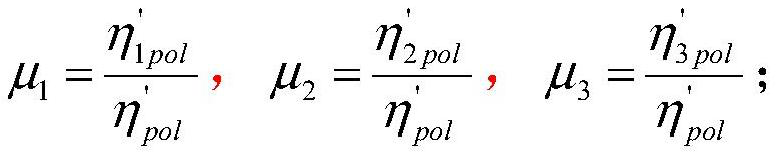

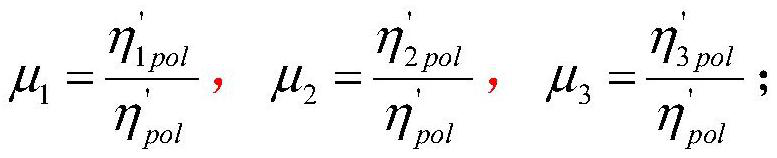

[0067] This embodiment provides a low pressure ratio axial flow compressor model stage performance calculation method, the axial flow compressor model stage is a three-stage axial flow compressor model stage, and the three-stage axial flow compressor model stage is divided into one Level, secondary and tertiary, the method proceeds in the following steps:

[0068] Step 1, collect parameters:

[0069] Collect the environmental parameters, flow parameters, inlet parameters, outlet parameters and pre-preparation parameters of the axial flow compressor model level, among which:

[0070] Environmental parameters: Pa is the atmospheric pressure, the unit is kPa; Ta is the atmospheric temperature, the unit is K;

[0071] Flow parameter: Qm is the mass flow rate, the unit is kg / s;

[0072] Import parameters: P 1st is the total inlet pressure in kPa; P 1s is the inlet static pressure in kPa; T 1p is the effective temperature of the inlet, in K;

[0073] Export parameters: P 2st ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com