Force and flow field correlation asynchronous measurement method and system

A measurement method and correlation technology, which can be applied to measurement devices, use of differential pressure to measure fluid velocity, aerodynamic tests, etc., can solve problems such as complex control operations, and achieve the effects of simple control operations, accurate judgment results, and simple operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

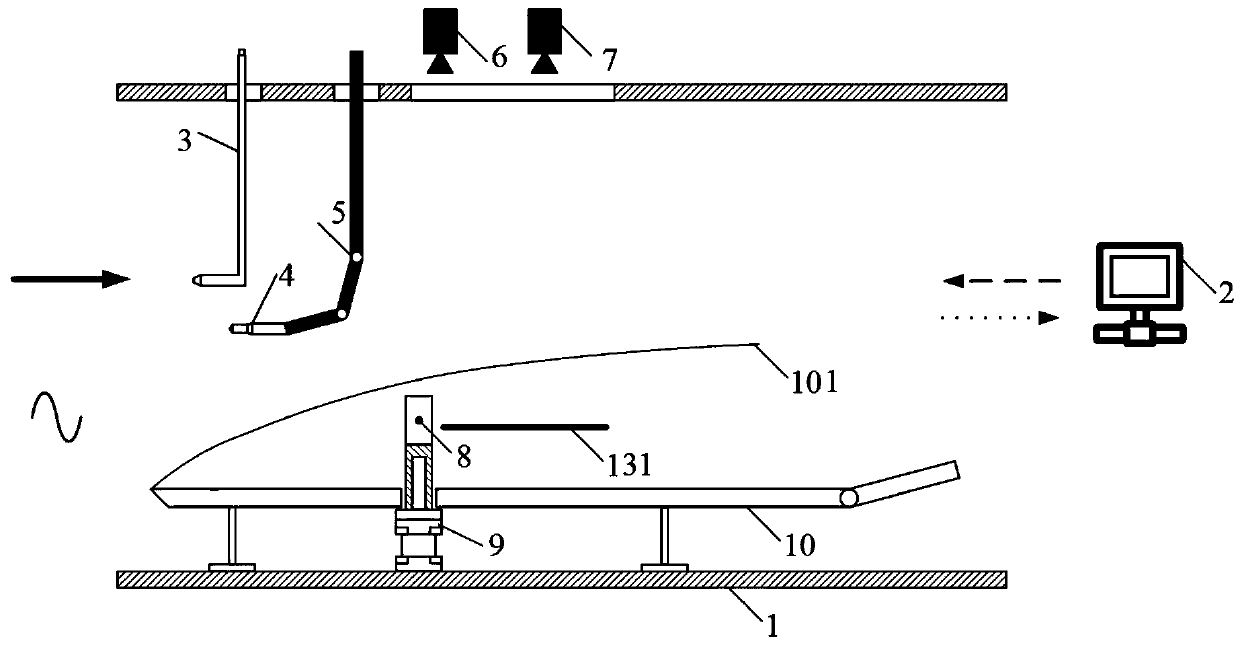

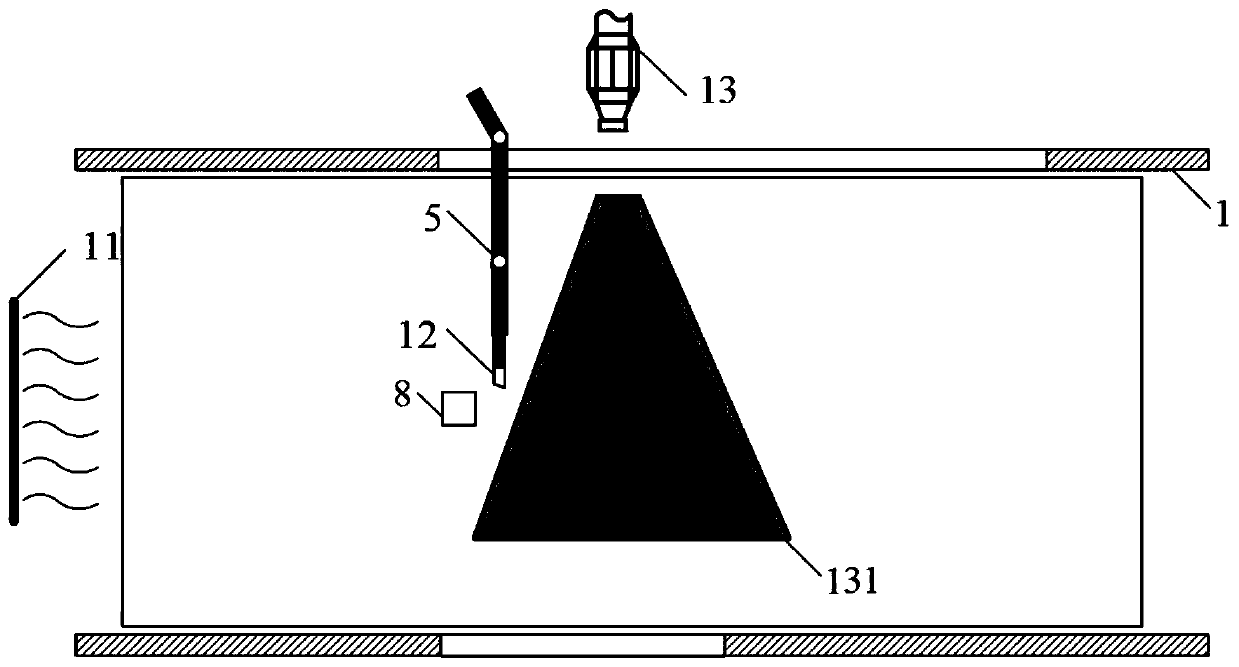

[0027] The fluid in this embodiment is air flow as an example, and the corresponding test area is a wind tunnel as an example. In other embodiments, the fluid may also be water flow. Basic as attached figure 1 with figure 2 Shown: the asynchronous measurement system for the correlation between force and flow field, including the test system built in the wind tunnel, and a flat plate 10 is set in the wind tunnel to create an experimental environment for the flat plate boundary layer. The test system includes a test model, a measuring device and a control terminal 2 . In this embodiment, the wind tunnel experiment of the influence of upstream disturbance on the aerodynamic load and wake characteristics of the square column model 8 in the boundary layer 101 is taken as an example. The test model is the square column model 8, and the square column model 8 is vertically arranged in the wind tunnel. Inside, the bottom end of the square column model 8 is installed in the middle of...

Embodiment 2

[0052] The difference from Embodiment 1 is that in order to obtain multiple measurement data, in this embodiment, when building the test system, the PIV camera 6 and the PIV laser 13 are also installed on the moving measurement mechanism 5, so that after completing one After the measurement data is measured, according to the test requirements, when the data of different positions need to be collected, the installation positions of the PIV camera 6, the PIV laser 13 and the hot wire probe 12 can be changed through the moving measurement mechanism 5, so as to realize the data collection of different positions .

Embodiment 3

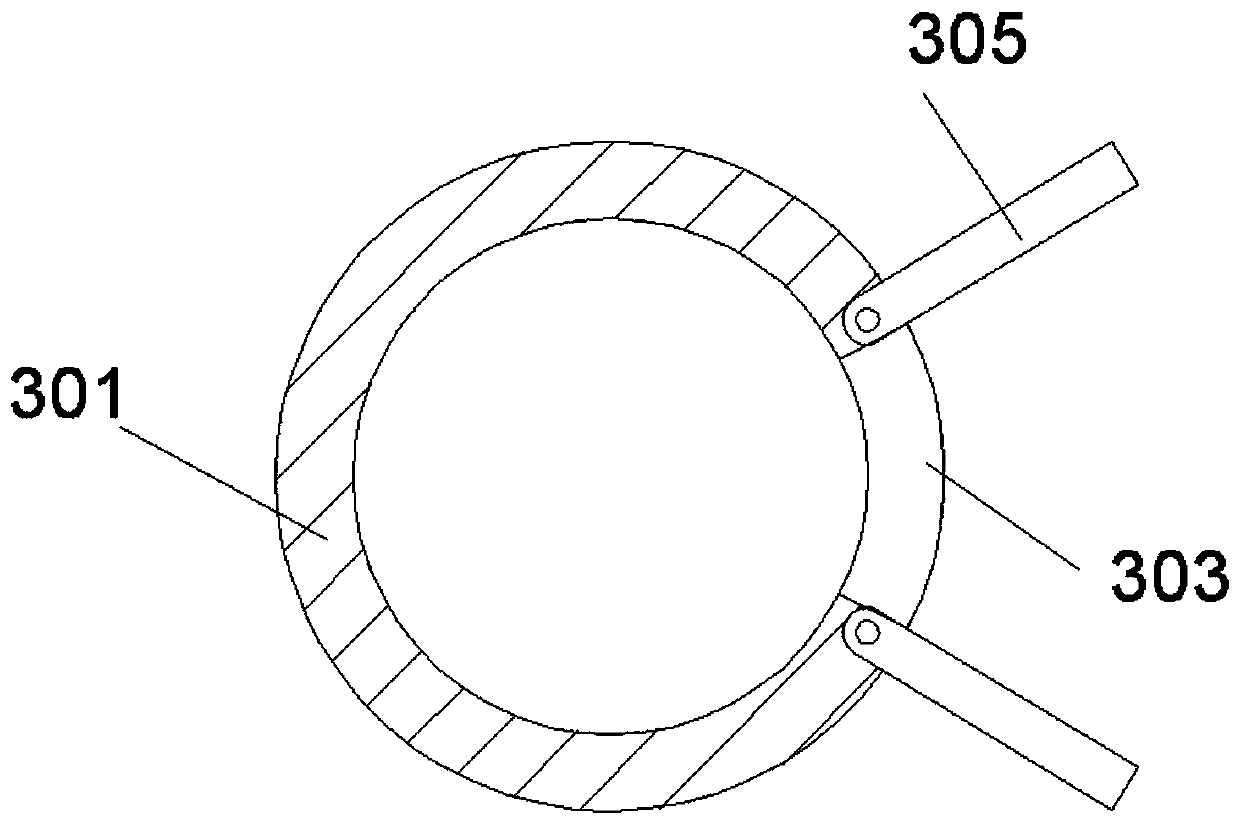

[0054] The difference from Embodiment 1 and Embodiment 2 is that the test system in this embodiment also includes a compensation subsystem, and the compensation subsystem includes a hollow column 301, such as image 3 As shown, the upper end of the hollow column 301 is provided with an air inlet, and one side of the hollow column 301 is provided with an air outlet 303. The hollow column 301 is vertically installed in the test area and is located at the center of the leeward side of the Pitot tube 3. The air outlet 303 Vertically arranged along the hollow column 301, the top of the hollow column 301 is provided with an air inlet.

[0055] The side wall of the air outlet 303 of the hollow column 301 is provided with an adjustment mechanism, and the adjustment structure includes swing plates 305 located on both sides of the air outlet 303 , and the connecting end of the swing plate 305 is hinged to the side wall of the air outlet 303 .

[0056] Considering that the airflow will g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com