Laying system for laying optical cables along low-friction pipeline and optical cable laying method thereof

A technology for optical cables and pipes, which is applied in the field of tools for floor equipment installation, which can solve problems such as inconvenient carrying, laborious manual pipe penetration, and limited routing length, etc., and achieve the effects of saving charging, shortening the construction period, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

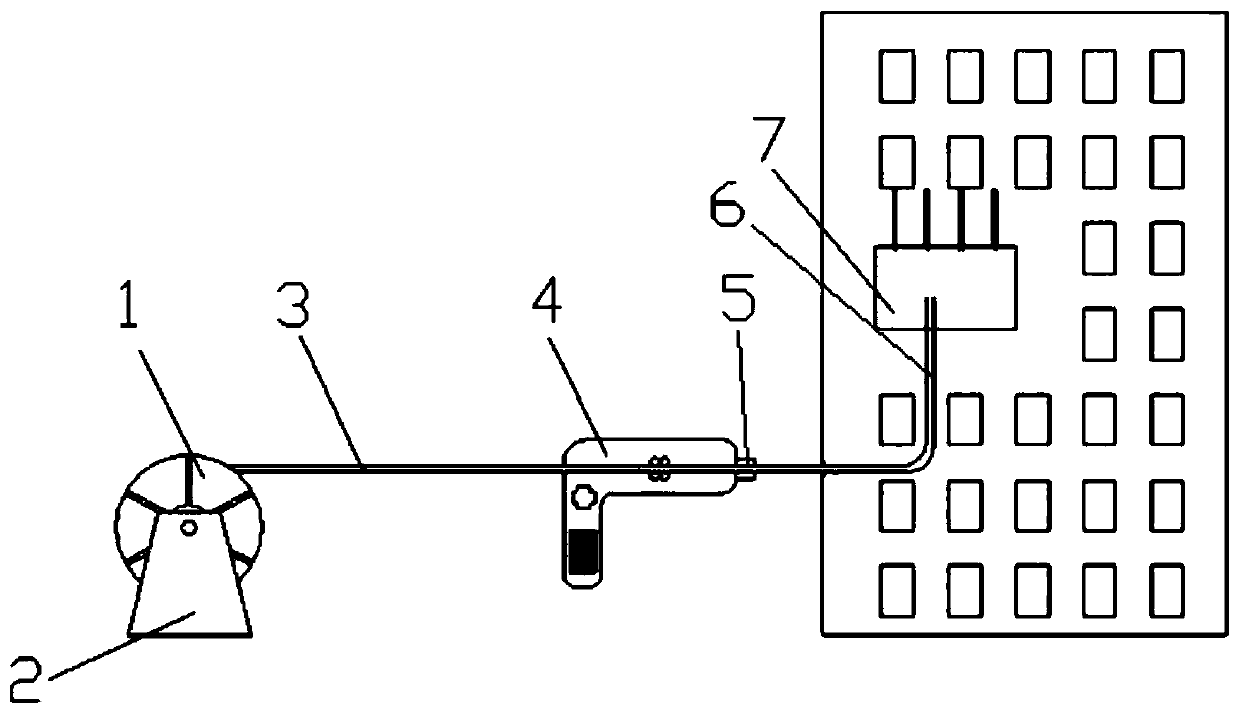

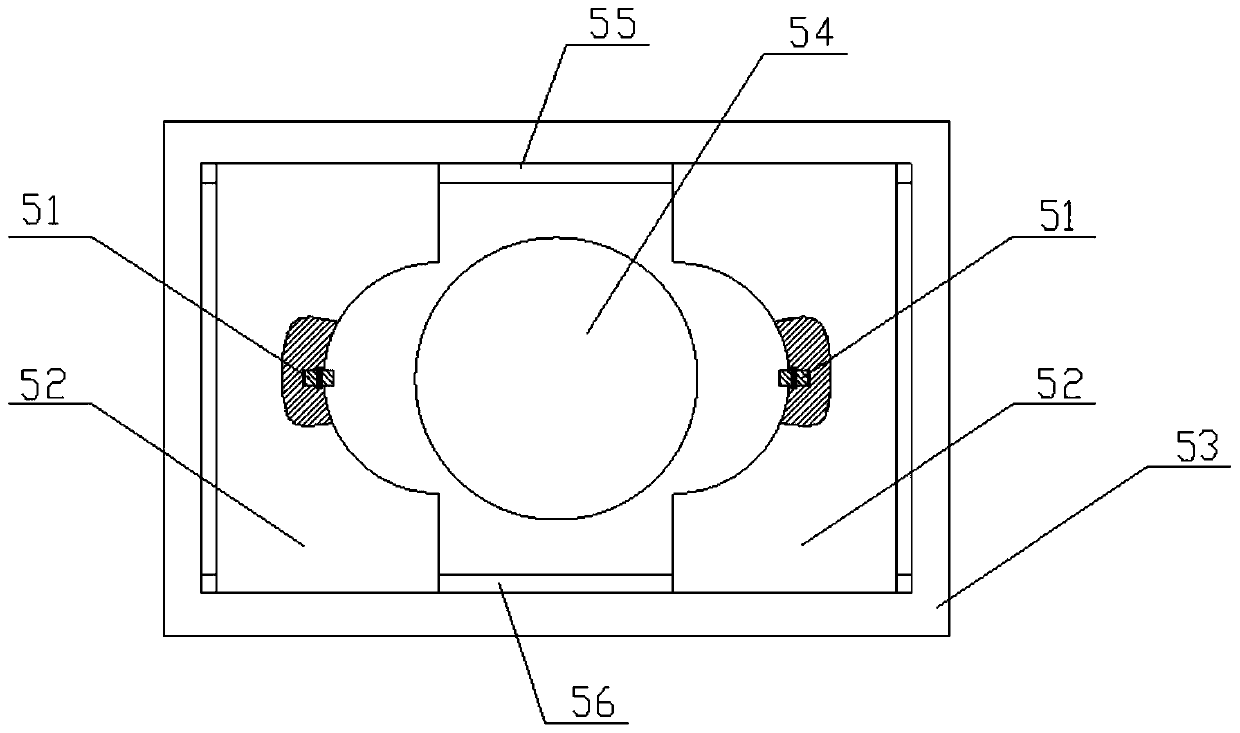

[0034] Embodiment: A deployment system for laying optical cables along a low-friction pipeline and a method for laying optical cables. In this embodiment, the friction coefficient of the inner wall of the low-friction pipeline is less than 0.25, and the inner wall of the wiring pipeline 6 is coated with a silicon core. The inner diameter size is preferably 5mm / 3.5mm, the maximum outer diameter of which is no more than 8mm, the optical cable adopts a small-sized structure with an outer diameter of less than 2.7mm, and the ratio of the outer diameter of the optical cable to the inner diameter of the wiring duct 6 is no greater than 0.85.

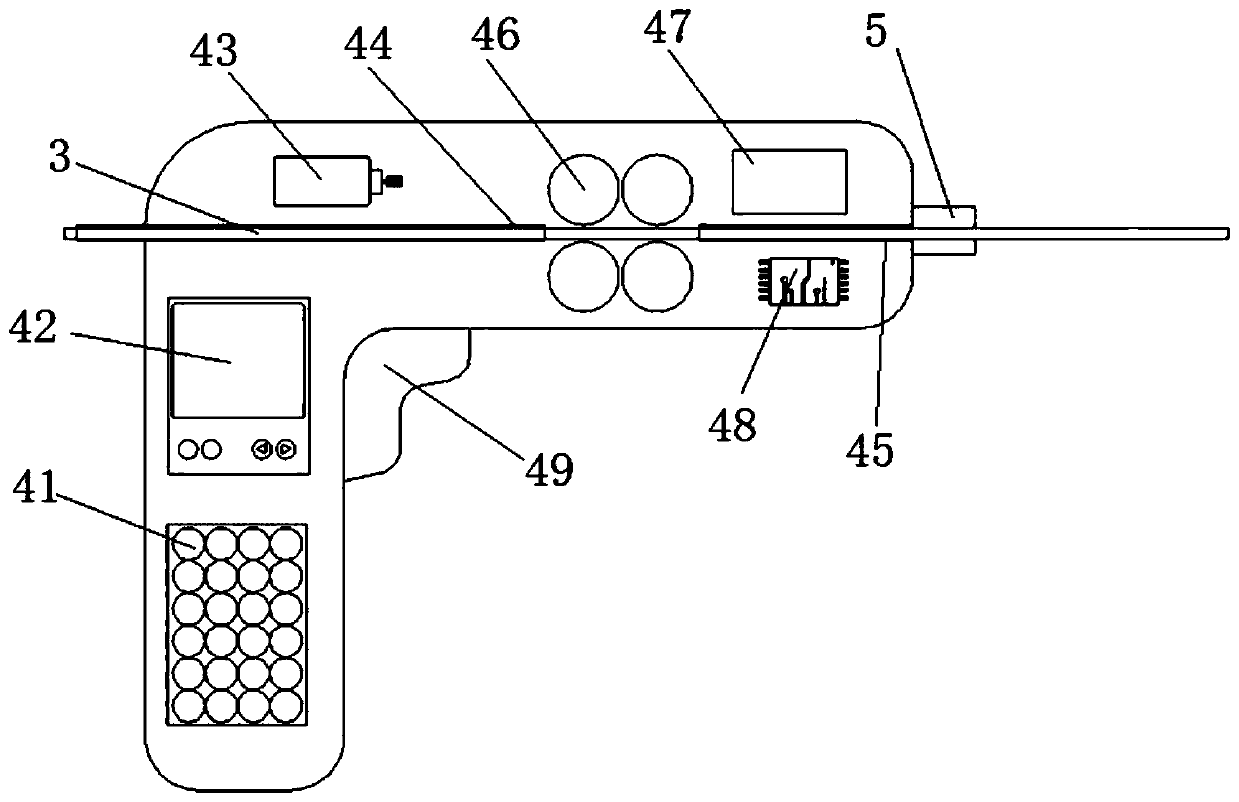

[0035] as attached figure 1 As shown, the deployment system includes an optical cable reel 1, an optical cable pay-off device 2 and an electric push device 4; an optical cable 3 is wound on the optical cable reel 1, and the optical cable reel 1 is installed on the optical cable pay-off device 2, and the optical cable pay-off device 2. A simple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com