Automobile production line quality management system and method

An automobile production line and quality management technology, applied in general control systems, control/regulation systems, comprehensive factory control, etc., can solve the problem that the production line cannot achieve quality trend prediction, and achieve quality prediction and traceability management, small size, cost low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

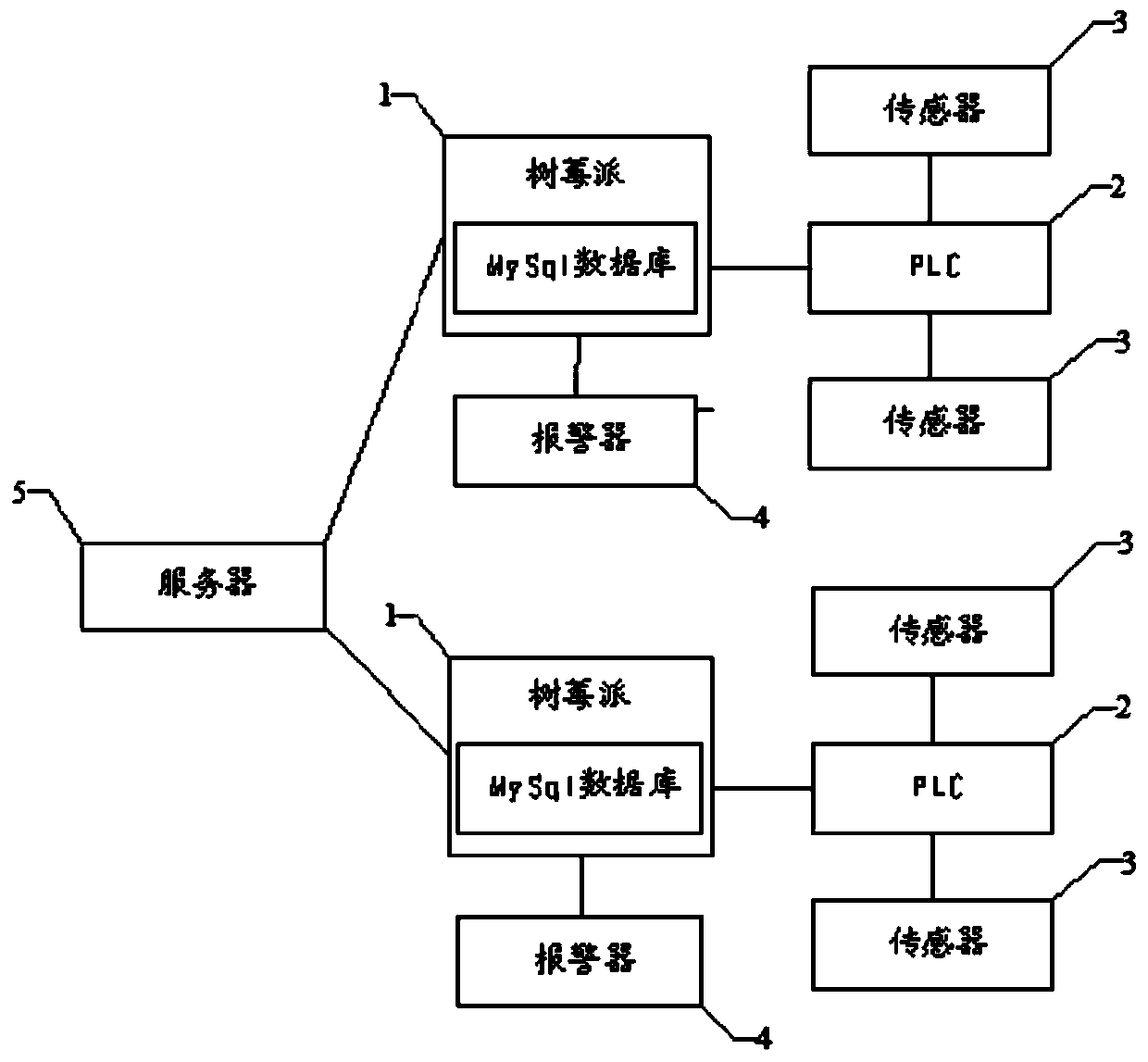

[0059] A kind of automobile production line quality management system, comprises PLC2, raspberry pie 1, server 5 and alarm 4; Described raspberry pie 1 is equipped with MySql database, and described PLC2 is connected with respectively being used for identifying product number and measurement process data The sensor 3, the raspberry pie 1 and the PLC2 are connected through MODBUS TCP / IP protocol communication, if the traditional PLC2 has no network cable port, RS-232 / 485 is used for communication, and the raspberry pie 1 and the alarm 4 are connected electrically Connection; the server 5 is connected to the Raspberry Pi 1 through communication.

[0060] The above-mentioned management method of the quality management system of the automobile production line includes the following steps:

[0061]S1: Raspberry Pi 1 reads the sensing data received by PLC2, the sensing data includes product number and measurement process parameters;

[0062] S2: Raspberry Pi 1 stores the sensing da...

Embodiment 2

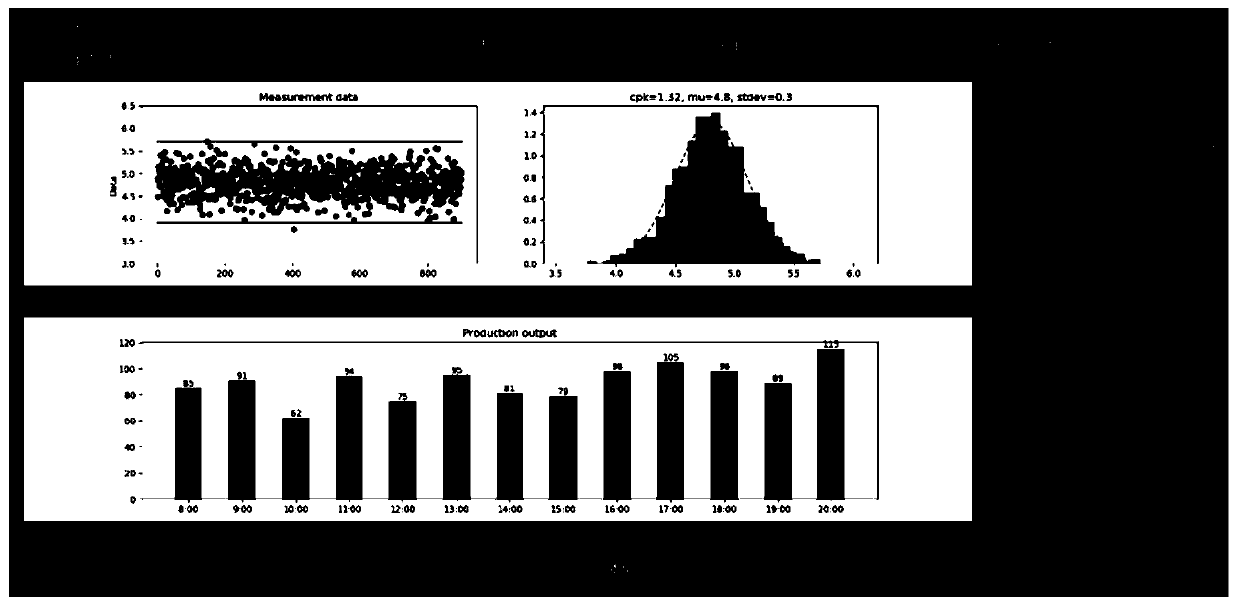

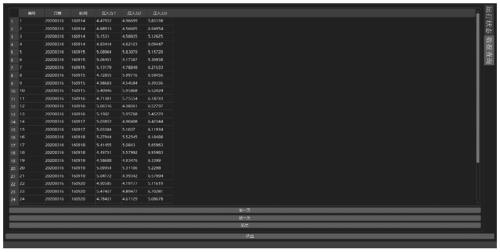

[0089] The spindle of the car is pressed into the production line, and the process includes: 1. Loading the spindle; 2. Pressing in the first layer of rotor core; 3. Pressing in the second layer of iron core; 4. Pressing in the third layer of iron core; 5. Complete the process; in the above process, the pressure value and position parameters need to be recorded, the corresponding pressure sensor 3 and position sensor 3 connected to PLC2 receive the sensing data, and the Raspberry Pi 1 reads the corresponding sensing data received by PLC2, And stored in the MySql database installed on the Raspberry Pi 1, read the corresponding data in real time through the Raspberry Pi 1, and calculate the X-bar-R control line through the Raspberry Pi 1, according to the 8 guidelines of GB / T4091-2001 Judging the quality trend and calculating the CPK value, the Raspberry Pi 1 judges whether there is any abnormality in the process of pressing the automobile spindle into the production line accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com