Strength evaluation method for tangential inclined connecting pipe under pipeline load effect

A technology of inclined pipe and load, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve problems such as unsafe, uneconomical, and conservative design, and achieve the effect of low computing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

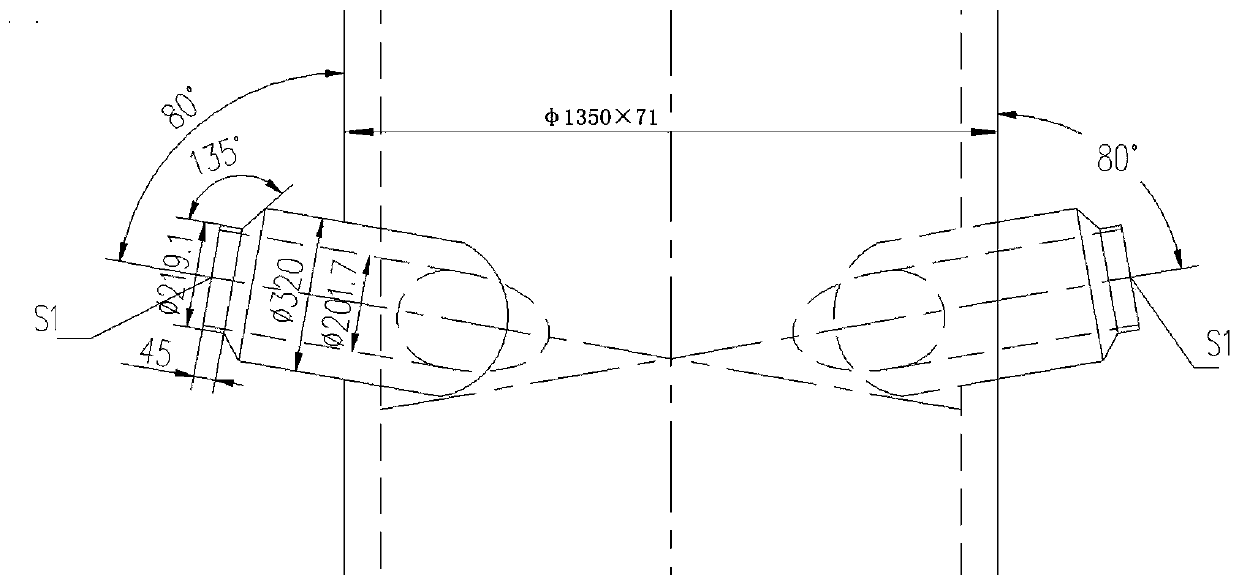

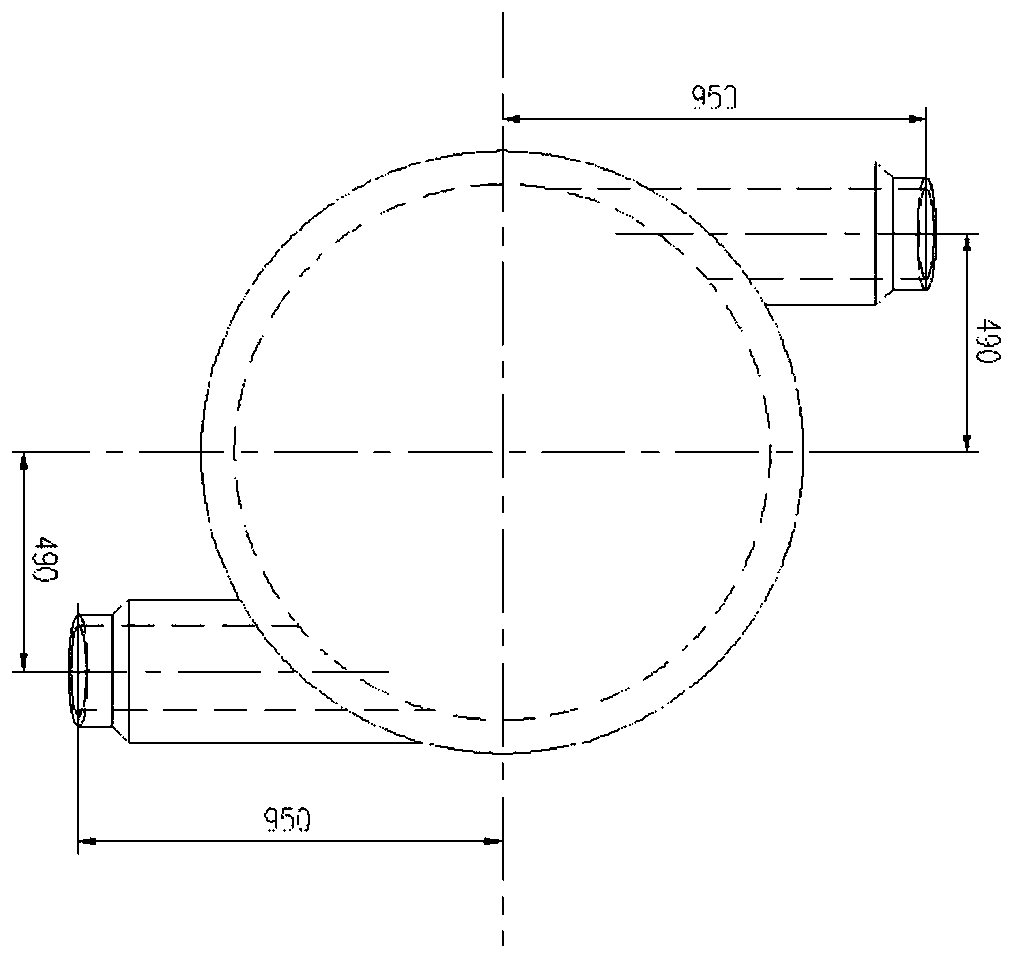

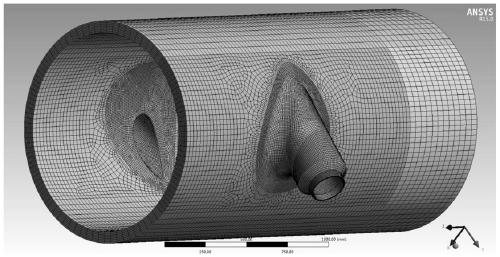

[0019] First, establish a three-dimensional solid model of the tangential miter pipe structure in the DM module of the ANSYS Workbench simulation platform; second, use Solid186 secondary elements to divide the mesh in the Meshing module; third, use the ideal elastic-plastic material book in the Static Structural module Structural relation, small deformation theory and equal-proportional loading are used to analyze the limit load of the tangential miter pipe structure under design conditions; at the same time, the linear elastic material constitutive relation and small deformation theory are used in the Static Structural module to analyze the tangential miter pipe structure Elastic stress analysis under the design conditions, and the evaluation of preventing local failure based on the sum of the three-dimensional principal stresses of film + bending in key parts; Fourth, the constitutive relationship of linear elastic materials and small deformation theory are used in the Static ...

Embodiment 2

[0021] According to the method for evaluating the strength of a tangentially mitered pipe under the action of a pipeline load described in Example 1, ANSYS Workbench is a collection of various analysis modules (such as structural analysis, fluid analysis, thermal analysis and electromagnetic analysis, etc.) launched by ANSYS. Large-scale simulation platform, DM is the modeling module integrated in ANSYS Workbench, Meshing is the mesh division module integrated in ANSYS Workbench, and Static Structural is the static analysis module integrated in ANSYS Workbench.

Embodiment 3

[0023] According to the strength evaluation method of a tangentially mitered pipe under the action of pipeline load described in Example 1, the ultimate load analysis method in preventing plastic collapse belongs to the plastic analysis method, and its evaluation criterion is to complete the plastic analysis for each load combination working condition, If the analysis reaches convergence, the stiffness is rated as acceptable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com