Longitudinal seam welding protection structure, barrel longitudinal seam welding device and corresponding welding method

A technology of longitudinal seam welding and protective structure, which is applied in the direction of auxiliary equipment, welding equipment, welding equipment, etc., to achieve the effect of optimizing the protection effect and introducing the effect of gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

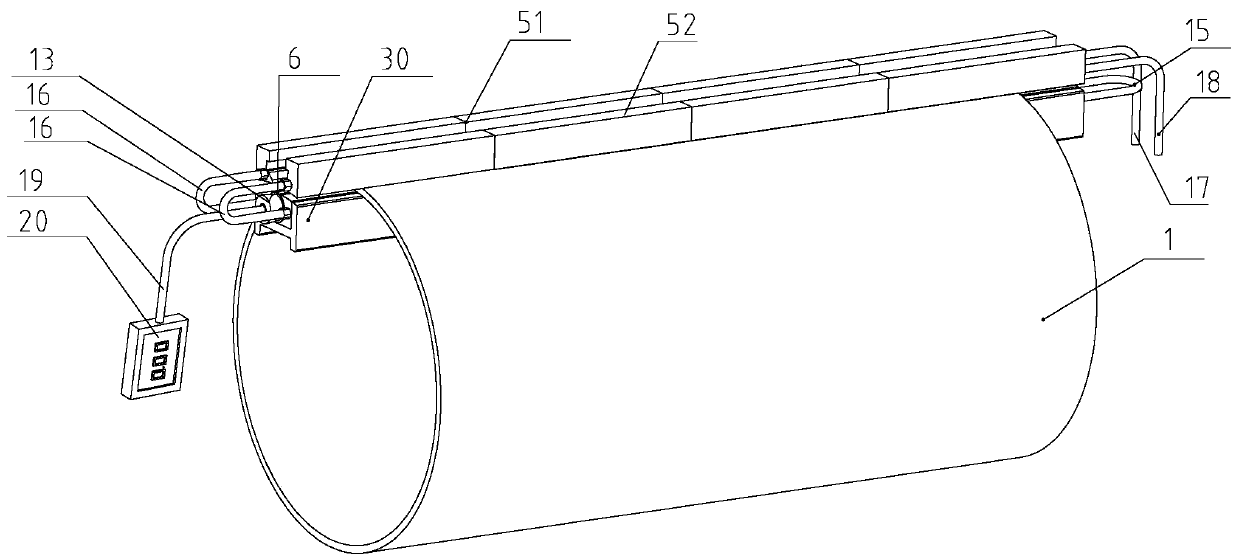

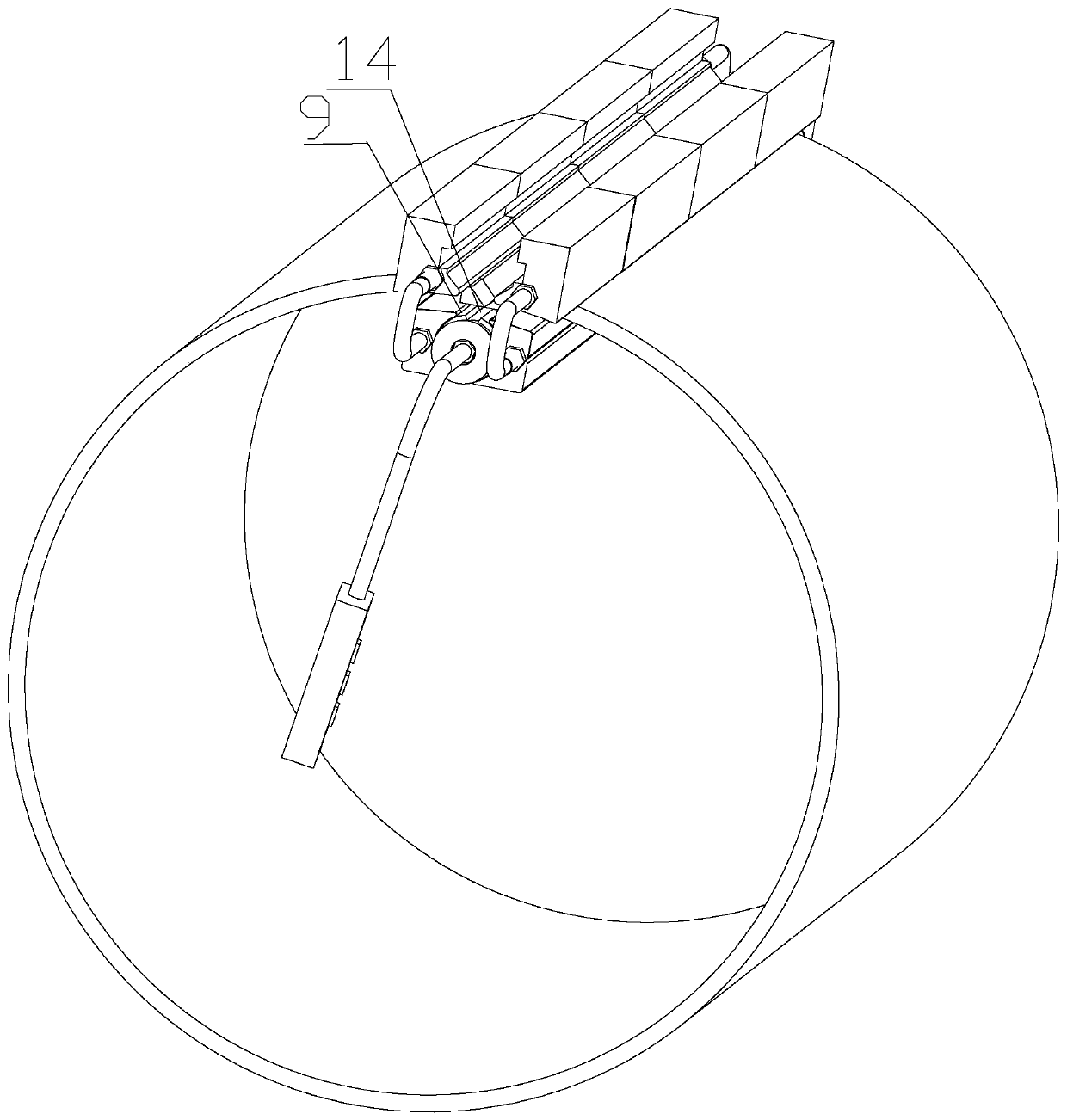

[0057] see Figure 1 to Figure 12 As shown, this embodiment provides a seam welding protection structure, including: a weld outer protection component and a weld inner protection component. The weld outer protection component here is located on the outside of the cylinder 1 during the welding process, while the welding inner protection component is located on the inside of the cylinder 1 during the welding process. , that is, the protective effect on the long longitudinal seam 2 of the cylinder body 1 during the welding process is jointly formed by the outer protective component of the weld and the inner protective component of the weld.

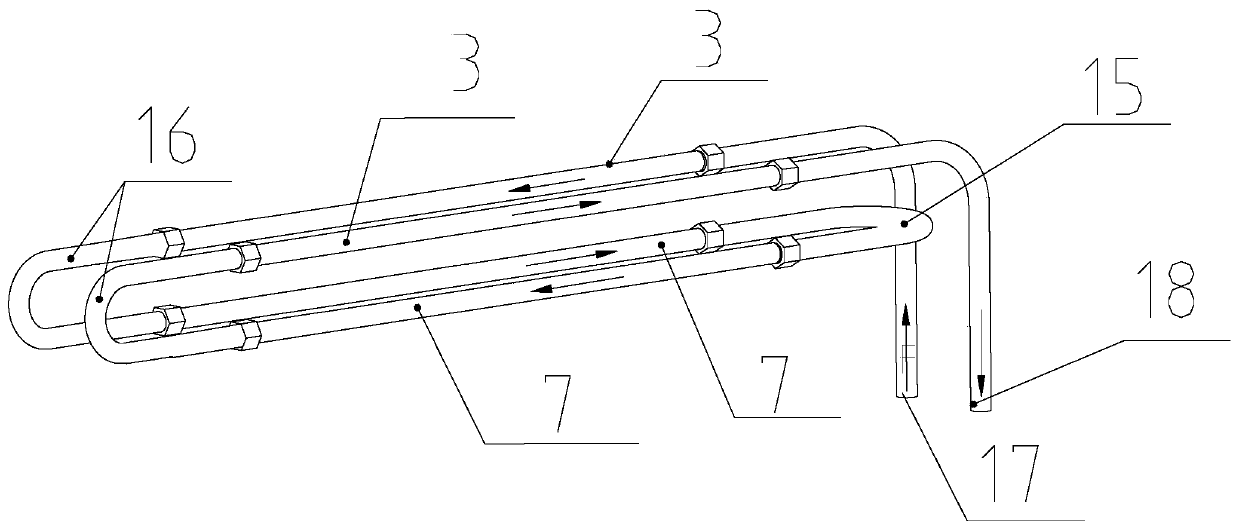

[0058] In detail, firstly, the weld outer protection assembly includes a pair of outer cooling pads adapted to abut against the cylinder body 1 on both sides of the longitudinal seam 2 from the outside of the cylinder body 1, and a pair of outer cooling pads along the length direction of the outer cooling pads. A pair of external cooling pi...

Embodiment 2

[0072] see Figure 1 to Figure 12As shown, on the basis of the longitudinal seam 2 welding protection structure in embodiment 1, this embodiment provides a cylinder longitudinal seam welding device, including: a cylinder supporting mechanism, a longitudinal seam 2 welding mechanism and the longitudinal seam welding mechanism of embodiment 1. Seam 2 welded protective structure. The cylinder support mechanism includes a support bracket 26 suitable for supporting the cylinder 1 from the bottom of the cylinder 1, and a base 27 fixedly connected with the bottom of the support bracket 26; The welding torch 28 for welding the longitudinal seam 2 and the mechanical arm 29 connected with the welding torch 28 to drive the welding torch 28 to move.

[0073] Considering the adequacy of effectively ensuring the contact between the protection component inside the weld of the longitudinal seam 2 welding protection structure and the outer wall and inner wall of the cylinder 1, the welding de...

Embodiment 3

[0078] On the basis of the cylinder longitudinal seam welding device in embodiment 2, this embodiment provides a cylinder longitudinal seam welding method, using the cylinder longitudinal seam welding device in embodiment 2; including:

[0079] Step S1: Pre-connect the longitudinal seam 2 of the long strip with spot welding after the cylinder 1 is manufactured, and weld an arc strike plate 41 with the same thickness as the cylinder 1 at one end of the cylinder 1, and weld on the other end of the cylinder 1 One end is welded with an arc extinguishing plate 42 equal in thickness to the cylinder body 1 .

[0080] Step S2: erect the cylinder body 1 on the support bracket 26 .

[0081] Step S3: Arranging the outer protection assembly of the weld seam on the outside of the cylinder body 1, and disposing the inner protection assembly of the weld seam on the inside of the cylinder body 1; 6 centers are aligned so that the shielding gas filled in the gas pipe 6 can form a gas shieldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com