Under-actuated multi-link type foldable routing inspection mechanical arm

A multi-link, robotic arm technology, applied in the field of inspection robots, can solve the problem of not being able to reach the maximum arm extension and minimum folding size of the robot arm, unable to adapt to the narrow inspection space of the inspection arm extension, and the inability of the multi-link robotic arm Completely expand and other issues to achieve the effect of reducing training time and training costs, improving battery life and work efficiency, and improving operational convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

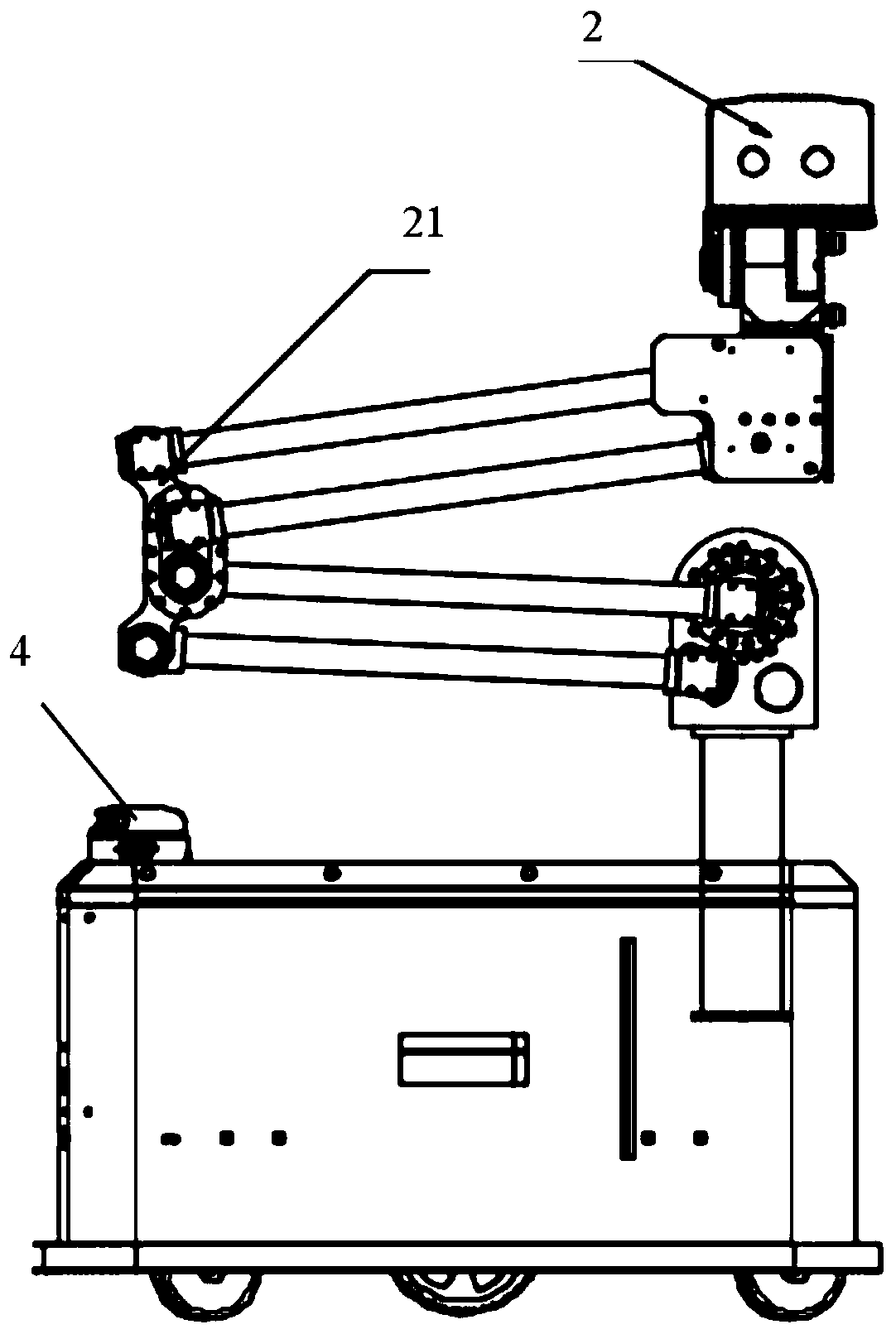

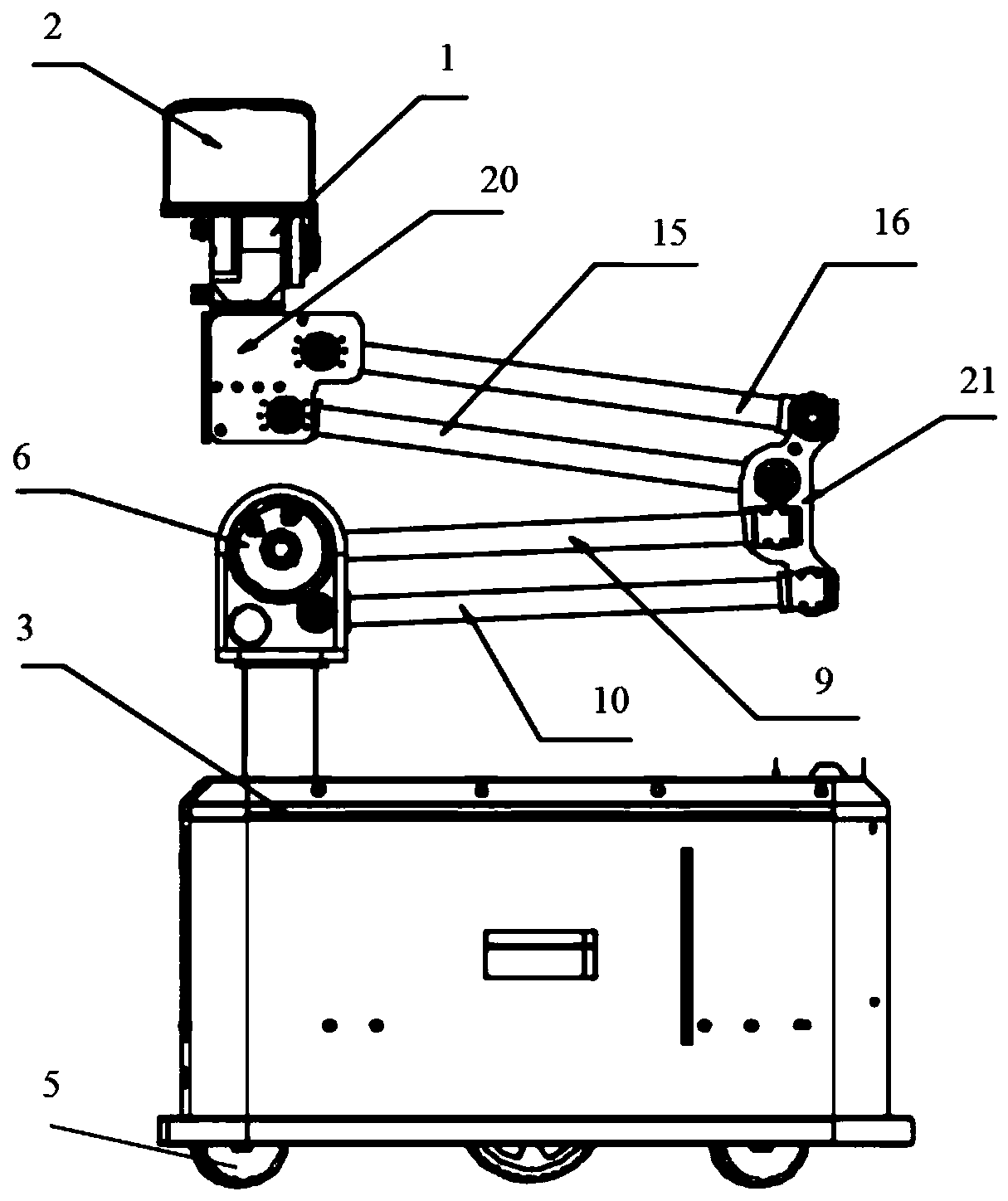

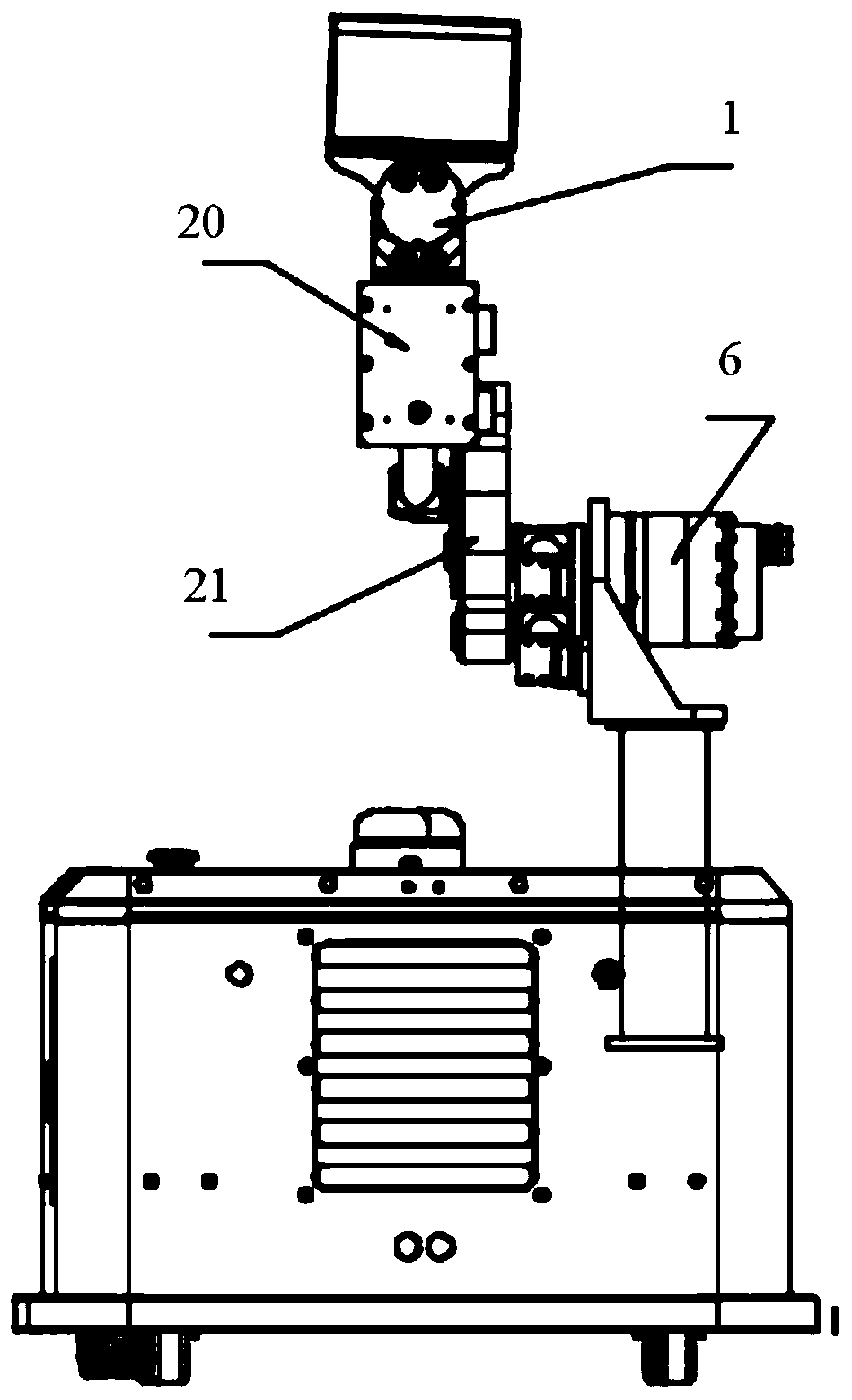

[0034] according to Figure 1-Figure 9 As shown, an underactuated multi-link foldable inspection robot arm includes a mobile installation platform, a robot arm, a two-degree-of-freedom platform 1 and a terminal device 2, and the robot arm is arranged on the mobile installation platform. Above, the two-degree-of-freedom pan-tilt 1 is set on the robotic arm, and the terminal device 2 is set on the two-degree-of-freedom pan-tilt 1 . The mobile installation platform part includes an installation platform 3, a walking part, a mobile power supply and a road condition video monitoring part, and the walking parts, the mobile power supply and the road condition video monitoring part are all arranged on the installation platform 3, and the The mobile power supply is electrically connected to the walking part, the road condition video monitoring part, the mechanical arm and the end respectively.

[0035] The installation platform 3 is used to install the mechanical arm, the walking part...

Embodiment 2

[0046] The similarities between this embodiment and Embodiment 1 will not be repeated, and the difference lies in:

[0047] The rod assembly is provided with at least three rod groups and two gear connection boxes 21, the rod assembly includes a first rod group, a second rod group and a third rod group, and the gear connection boxes 21 are connected to the first gear respectively. The box 21 and the second gear are connected to the box 21, the structure of the first rod group is the same as that of the first rod group in Embodiment 1, and the structure of the second rod group is the same as that of the second rod group in Embodiment 1, The third rod group includes a third connecting rod on the left side, a third connecting rod on the right side, and a third shaft connecting member, and the third rotating shaft connecting member is arranged on the third connecting rod on the left side and the third connecting rod on the right side. On the three connecting rods, both the first g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com