High-rise building glass wall cleaning robot

A technology for cleaning robots and architectural glass, applied in applications, manipulators, motor vehicles, etc., can solve the problems of affecting indoor lighting, inability to move freely, and consume a lot of physical strength, and achieve improved cleaning quality, strong obstacle crossing function, and high structural strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] This embodiment is a robot for cleaning glass walls of high buildings.

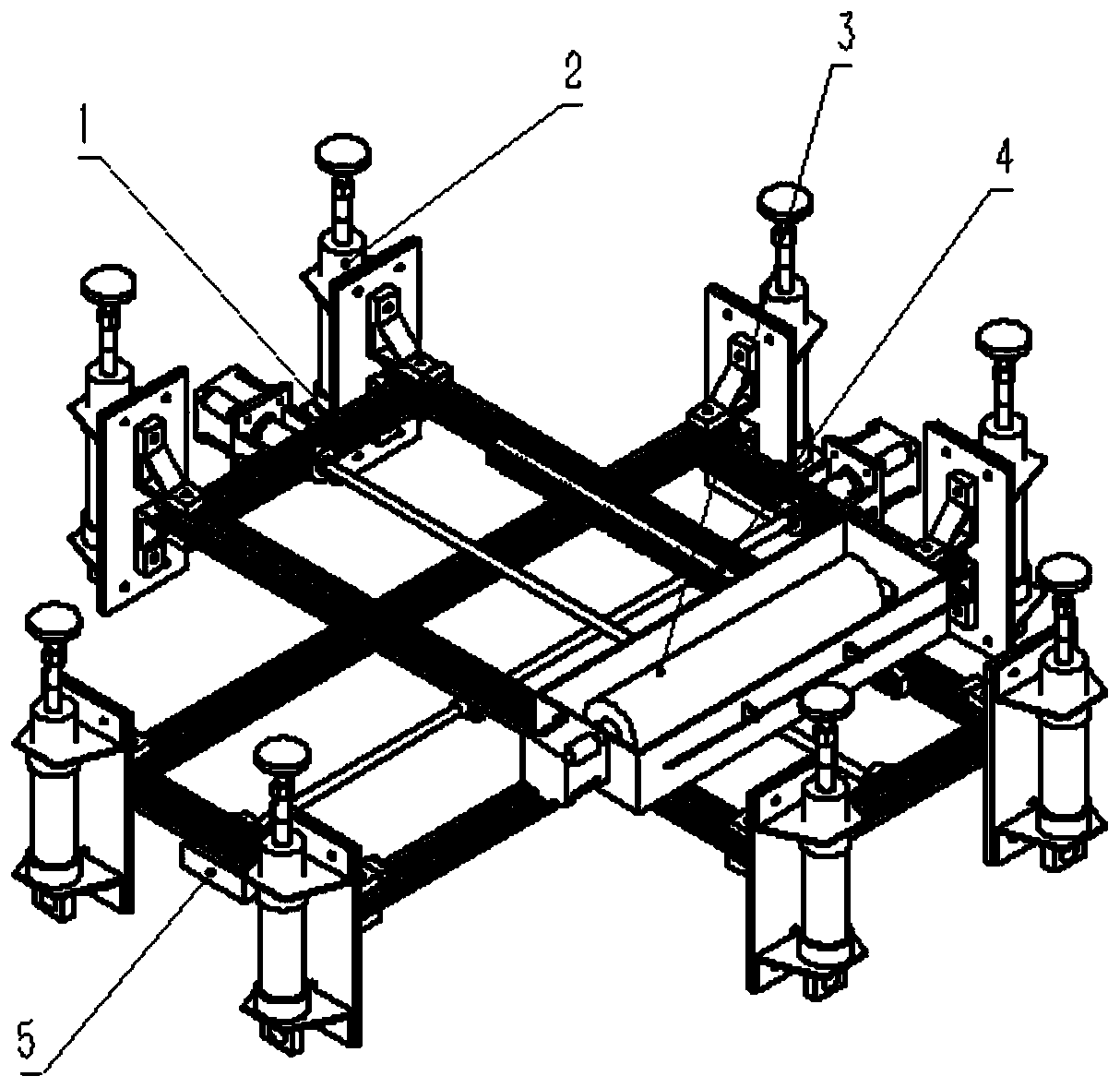

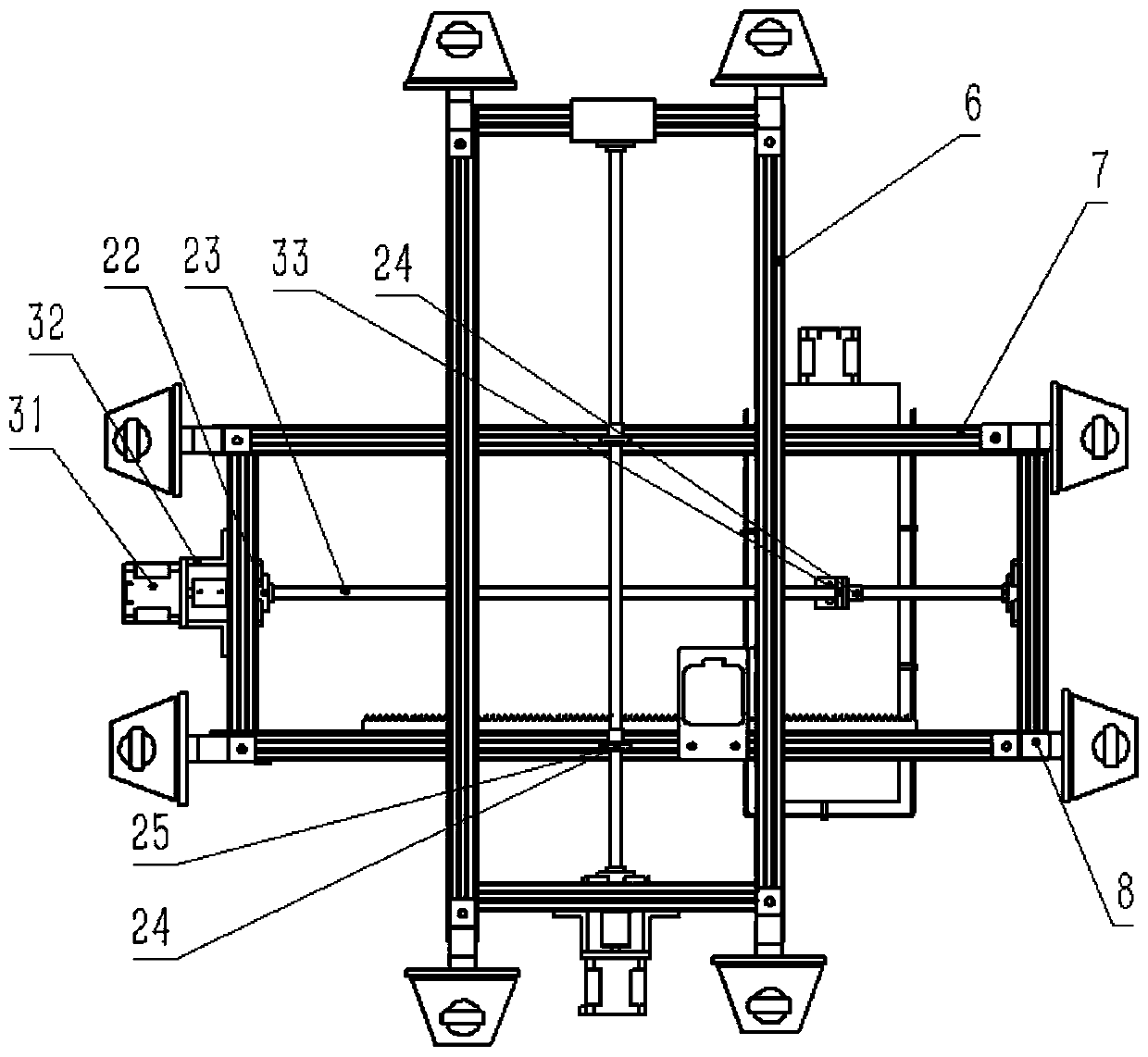

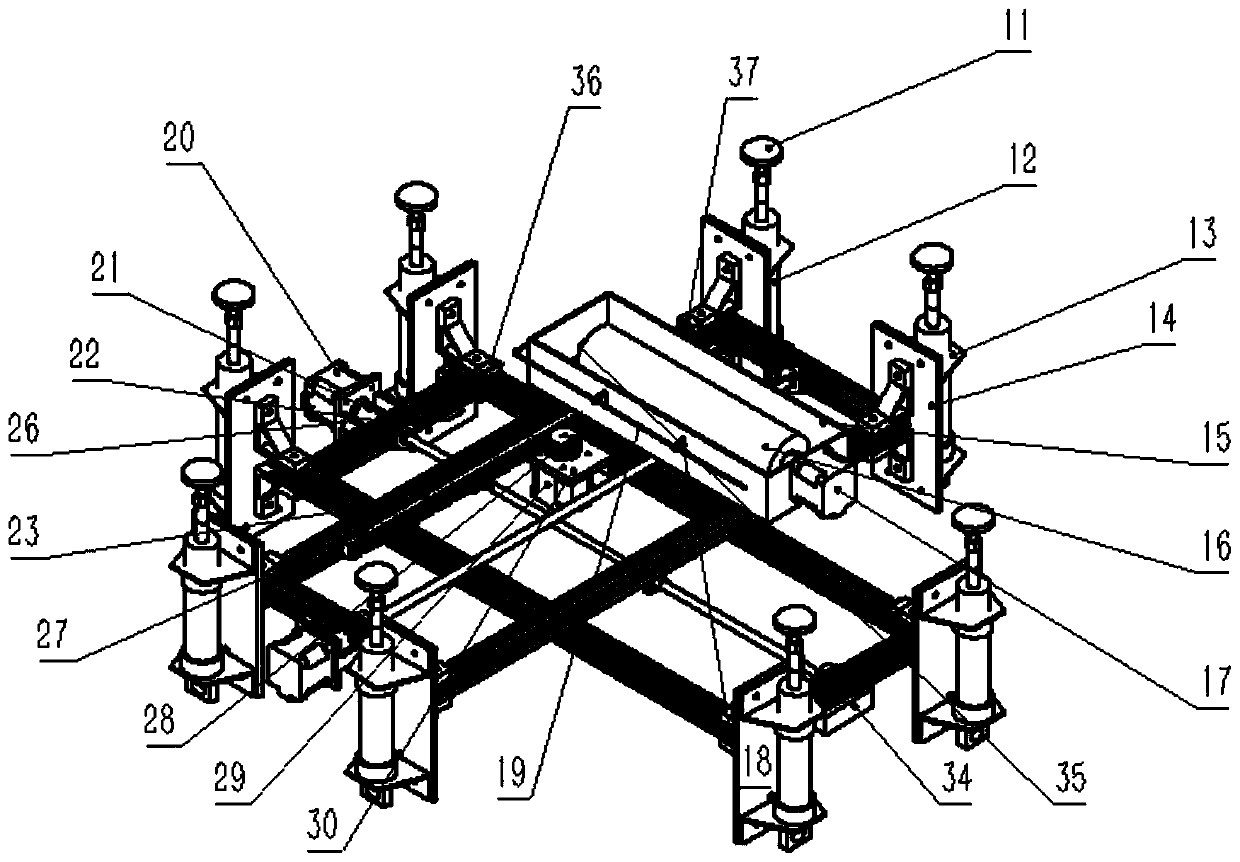

[0026] refer to figure 1 , figure 2 , image 3 , Figure 4 , the present embodiment is used for the glass wall surface cleaning robot of high buildings, and is made up of main body support 1, adsorption device 2, cleaning device 3, moving mechanism 4 and control system 5; Wherein, main body support 1 comprises vertical frame 6, horizontal frame 7 , right-angle connector 8, bolt 9 and slide block 10, vertical frame 6 and horizontal frame 7 are rectangular frame structures, vertical frame 6 and horizontal frame 7 are fixedly connected by right-angle connector 8 respectively, slide block 10 is installed on the vertical The profile grooves of the frame and the horizontal frame are connected into a cross-shaped structure by bolts, and are respectively placed at the contact points of the horizontal frame 7 and the vertical frame 6, so that the horizontal frame 7 and the vertical frame 6 are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com