A sf buried oil tank

An oil tank and tank body technology is applied in the field of oil storage, which can solve the problems of accidental well fall, poor light in the operation well, and unfavorable maintenance by operators, and achieves the effect of good sealing effect and improved timeliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

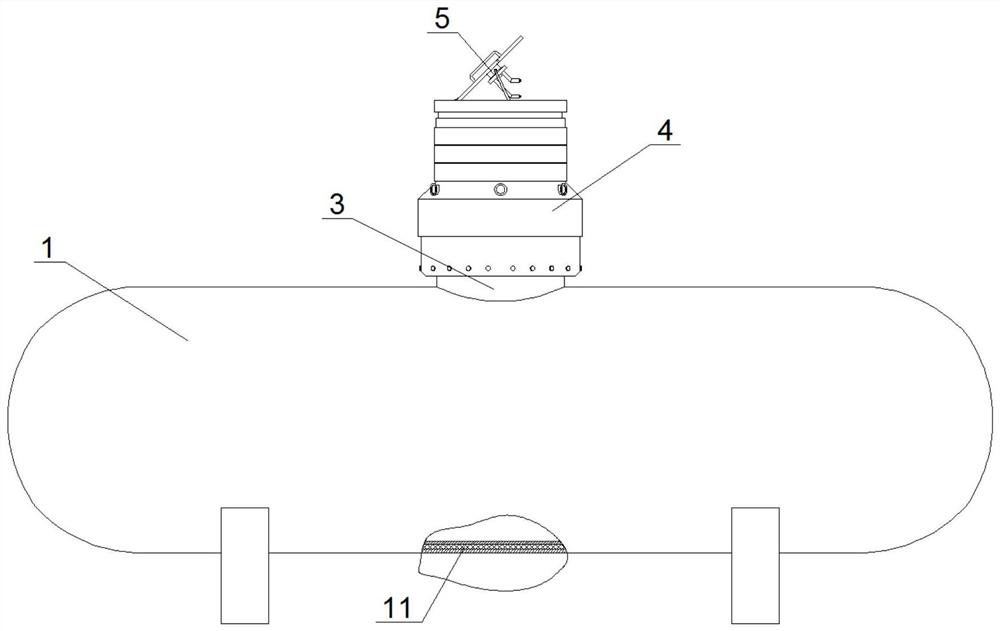

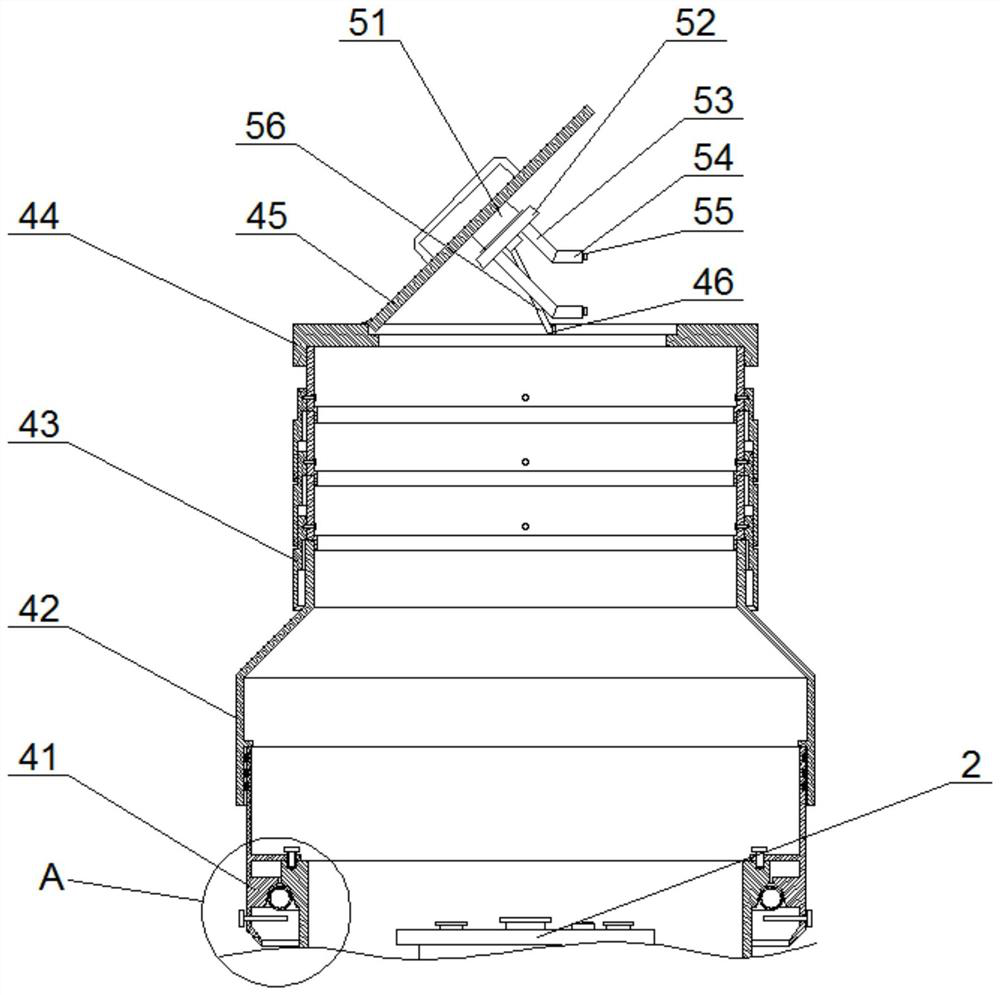

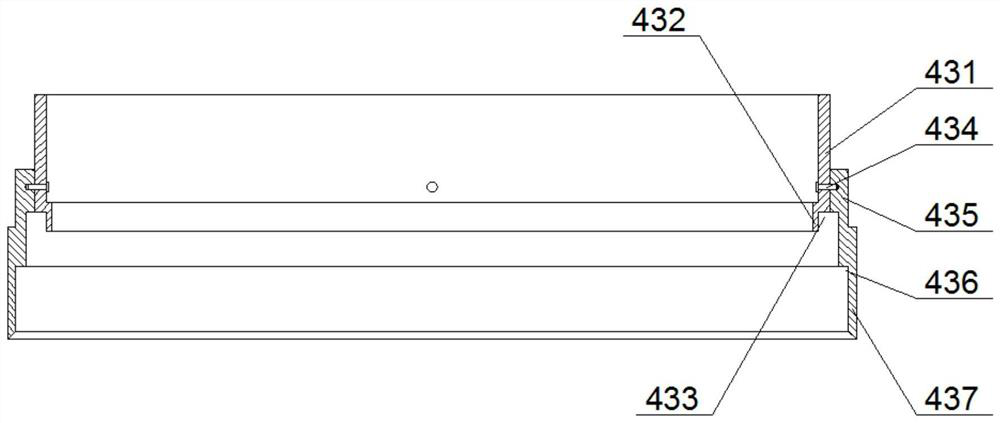

[0029] like Figure 1 to Figure 4As shown, the SF buried oil tank provided in this embodiment includes a tank body 1 and a manhole 2 and a well seat 3 arranged on the tank body 1. In this embodiment, in order to be able to monitor in real time whether the inner tank body leaks, The tank body 1 includes an inner resin-rich layer, an inner anti-seepage layer, a through-gap layer 11, an outer anti-seepage layer, and an outer resin-rich layer from the inside to the outside, wherein the inner and outer resin-rich layers are made of noon glass fiber surface felt, The resin content should not be less than 90%. The inner and outer anti-seepage layers are made of alkali-free glass fiber chopped strand mat or spray yarn, and the resin content is 65-75%. The through-gap layer 11 is filled with 3D fiberglass fabric material, mainly a composite of 3D glass fiber fabric and resin, and an anti-leakage detector is provided through the interstice layer 11, and the anti-leakage detector include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com