Rare-earth processing wastewater dosing, separating and purifying integrated device

A technology for processing wastewater and separating devices, which is applied in the fields of natural water treatment, water/sewage treatment, chemical instruments and methods, etc., and can solve the problems of excessive accumulation of filter devices, reduced filtration speed, and low mixing efficiency of wastewater and drugs. Achieve the effect of improving processing efficiency and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

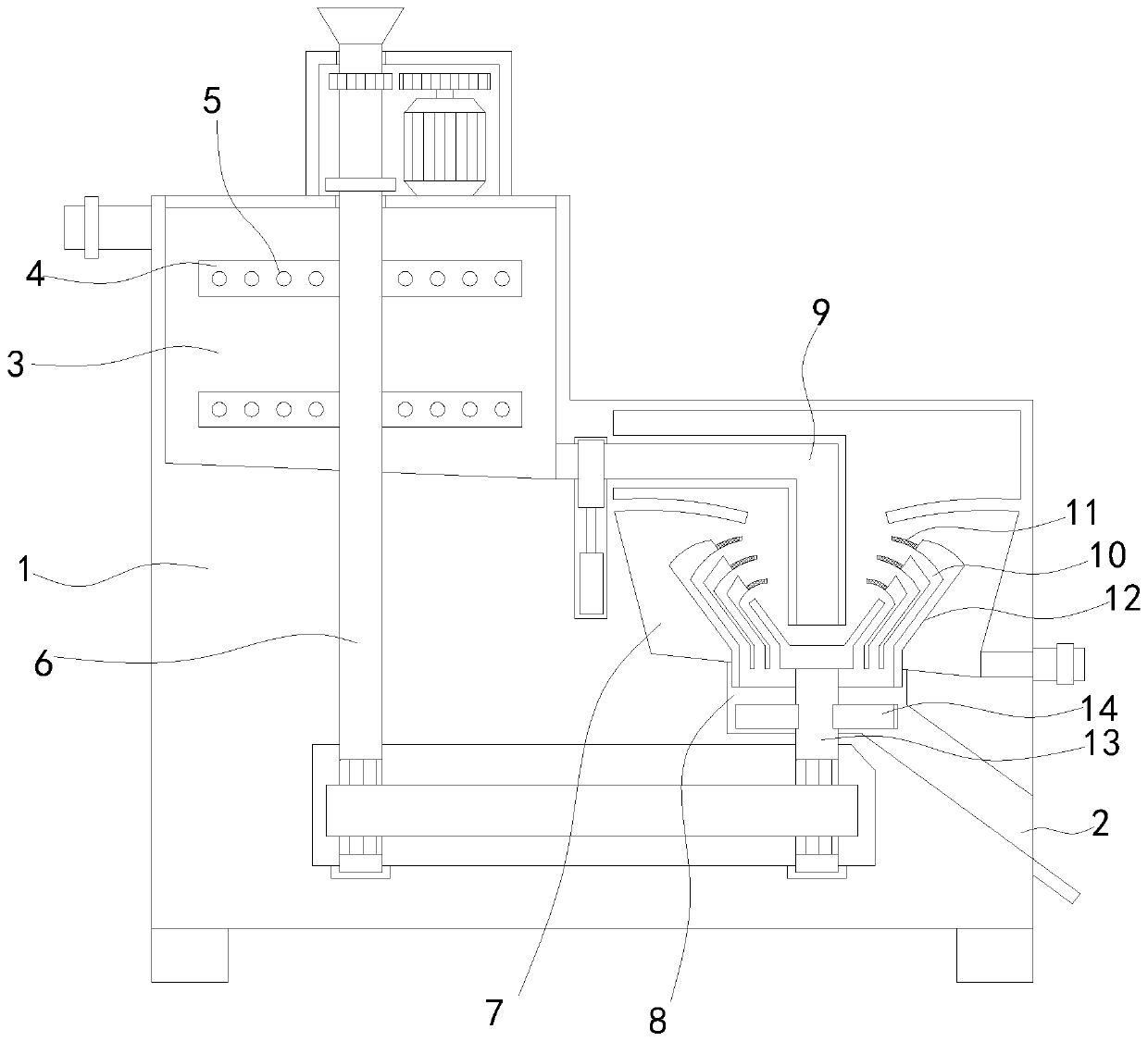

[0025] see Figures 1 to 7 , a schematic diagram of planar structure and schematic diagram of three-dimensional structure of an integrated device for dosing, separation and purification of rare earth processing wastewater.

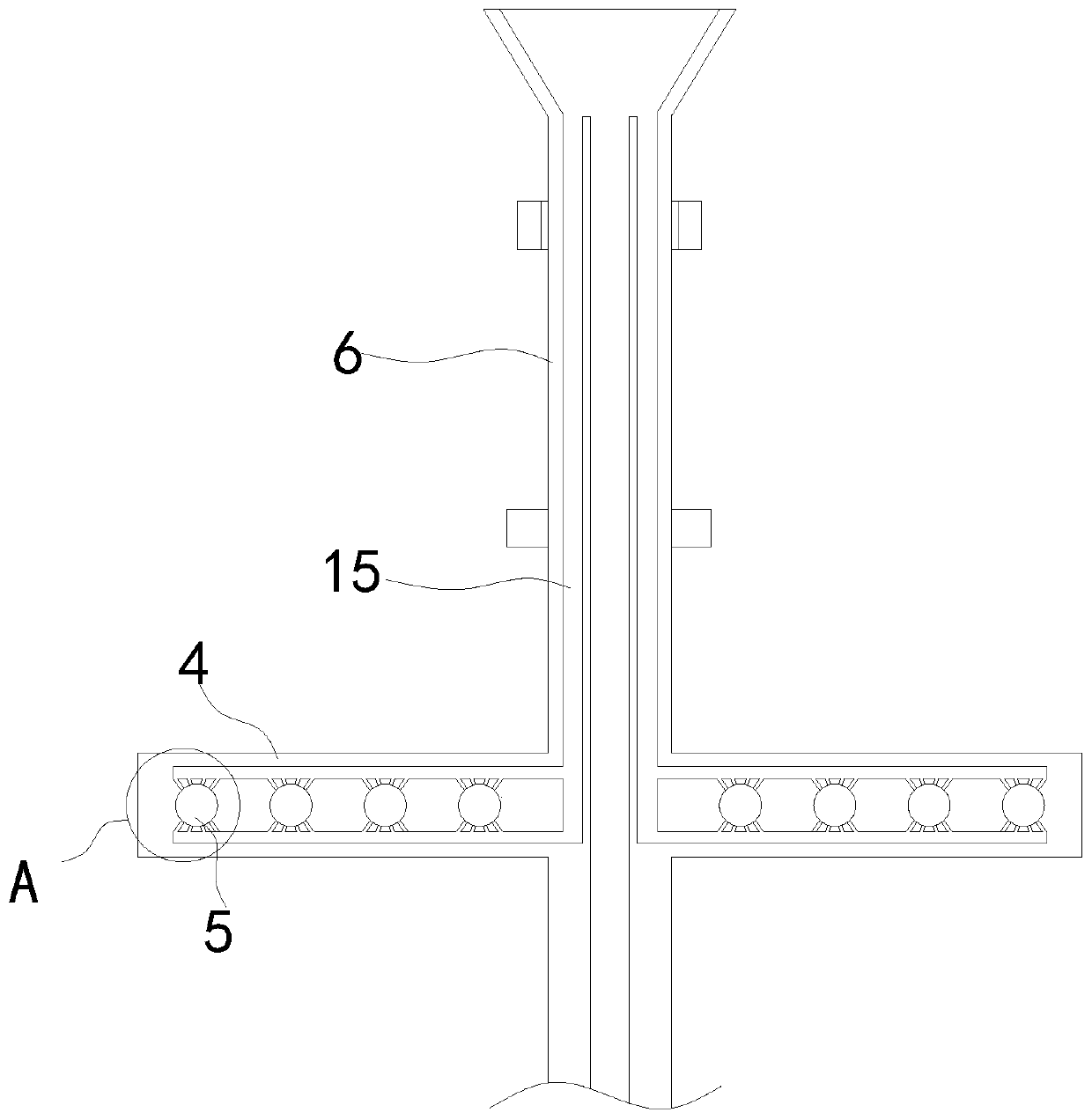

[0026] An integrated device for dosing, separation and purification of rare earth processing wastewater, comprising a device main body 1, a stirring rod 6 is fixedly installed on the left side inside the device main body 1, a stirring and dosing plate 4 is fixedly installed on the outer side of the upper end of the stirring rod 6, and a stirring and dosing plate 4 is fixedly installed on the outside of the upper end of the device main body 1, and the right side of the device main body 1 is An impurity separation device 12 is fixedly installed.

[0027] In a specific implementation, a dosing chamber 3 is provided at the upper left side of the main body 1 of the device, and the stirring and dosing plate 4 is arranged inside the dosing chamber 3, so that when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com