Low-cost high-strength C45 fine aggregate concrete and preparation method thereof

A fine stone concrete, high-strength technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of concrete unable to meet market needs, reduced concrete strength, and reduced compressive capacity, etc. Filling effect, good self-compactness and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

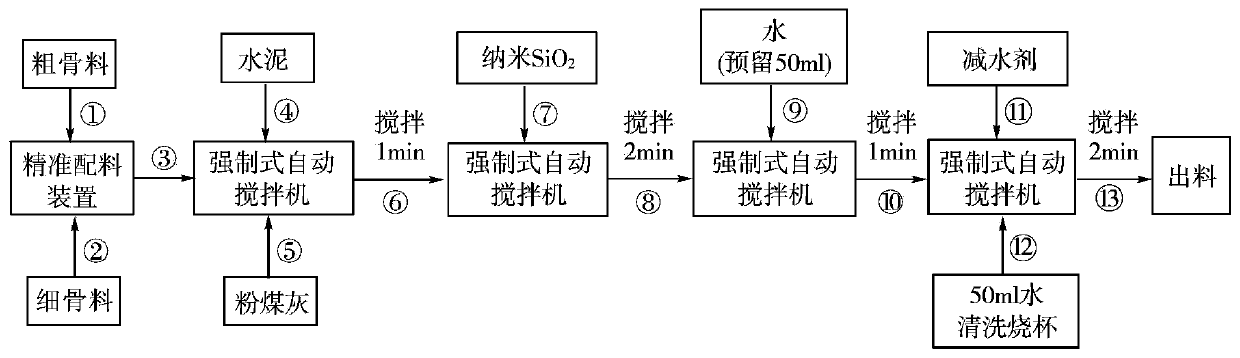

[0029] according to figure 1 A low-cost high-strength C45 fine stone concrete is shown, the basic materials used in the fine stone concrete are composed of coarse aggregate, fine aggregate, cementitious material, active material, admixture and water, and are calculated according to the unilateral amount , the consumption of each component of this fine stone concrete is as follows:

[0030] Water cement ratio: 0.35

[0031] Gravel: 1118kg / m 3

[0032] Sand: 602kg / m 3

[0033] Cement: 500kg / m 3

[0034] Admixture: 6.02kg / m 3

[0035] Water: 175kg / m 3

[0036] Wherein, the coarse aggregate is specifically grade 9.5 crushed stone with a maximum diameter of 9.5 mm;

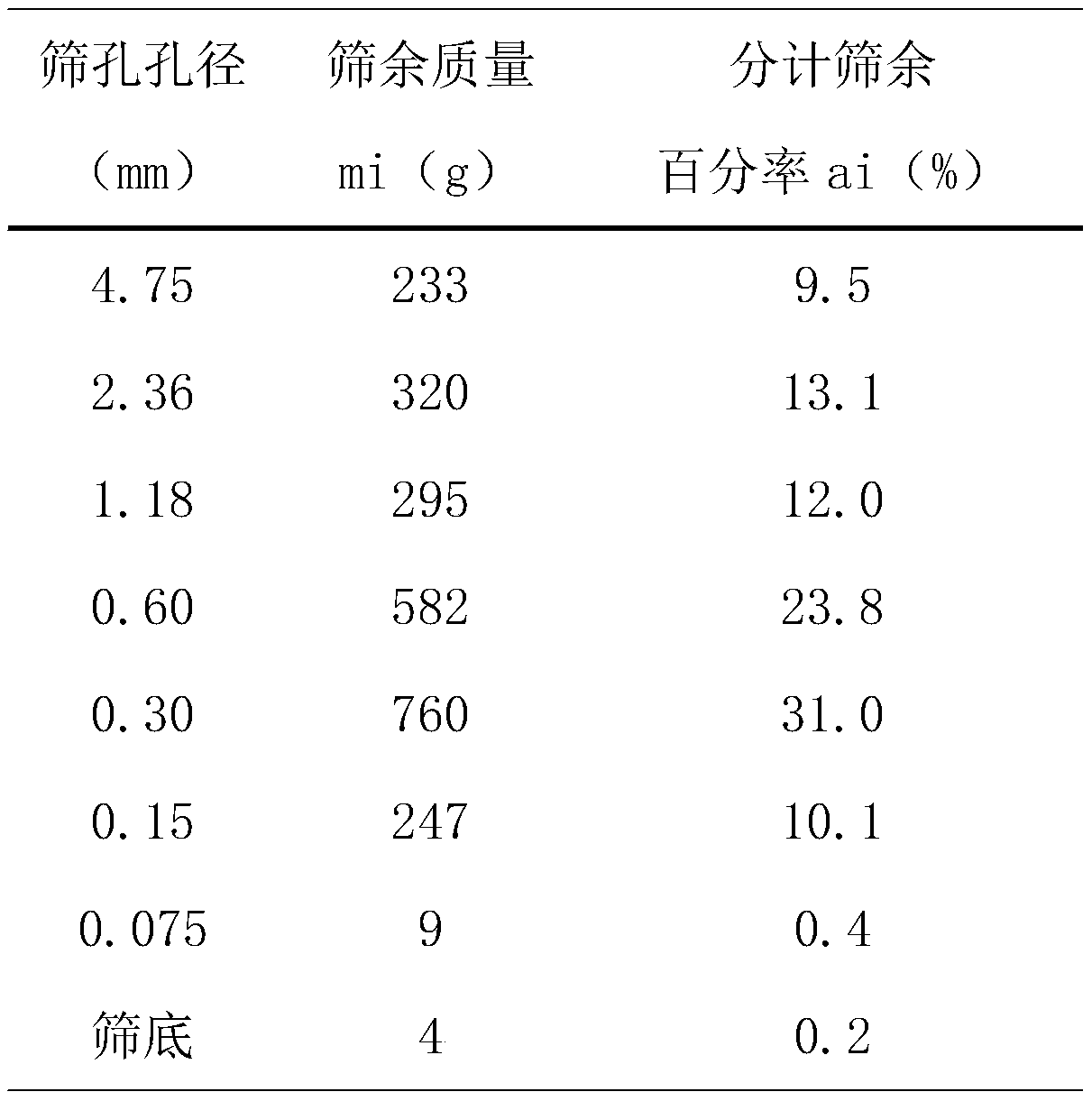

[0037] The fine aggregate is specifically medium-coarse sand of 0.15-0.5mm;

[0038] Described cement is specifically P.O42.5 ordinary portland cement;

[0039] The fly ash is Class II fly ash discharged from the power station;

[0040] The average particle size of the nano-silica is 7-40nm, and the param...

Embodiment 2

[0049] according to figure 1A low-cost high-strength C45 fine stone concrete is shown, the basic materials used in the fine stone concrete are composed of coarse aggregate, fine aggregate, cementitious material, admixture and water, and the fine stone concrete The dosage of each component of stone concrete is as follows:

[0050] Water cement ratio: 0.35

[0051] Gravel: 1118kg / m 3

[0052] Sand: 602kg / m 3

[0053] Cement: 450kg / m 3

[0054] Fly ash: 50kg / m 3

[0055] Admixture: 6.02kg / m 3

[0056] Water: 175kg / m 3

[0057] The amount of fly ash is 10% of the cementitious material, and the fly ash is mixed with nano silicon dioxide;

[0058] Wherein, the coarse aggregate is specifically grade 9.5 crushed stone with a maximum diameter of 9.5 mm;

[0059] The fine aggregate is specifically medium-coarse sand of 0.15-0.5mm;

[0060] Described cement is specifically P.O42.5 ordinary portland cement;

[0061] The fly ash is Class II fly ash discharged from the power...

Embodiment 3

[0071] according to figure 1 A low-cost high-strength C45 fine stone concrete is shown, the basic materials used in the fine stone concrete are composed of coarse aggregate, fine aggregate, cementitious material, admixture and water, and the fine stone concrete The dosage of each component of stone concrete is as follows:

[0072] Water cement ratio: 0.35

[0073] Gravel: 1118kg / m 3

[0074] Sand: 602kg / m 3

[0075] Cement: 400kg / m 3

[0076] Fly ash: 100kg / m 3

[0077] Admixture: 6.02kg / m 3

[0078] Water: 175kg / m 3

[0079] The amount of fly ash is 20% of the cementitious material, and the fly ash is mixed with nano silicon dioxide;

[0080] Wherein, the coarse aggregate is specifically grade 9.5 crushed stone with a maximum diameter of 9.5 mm;

[0081] The fine aggregate is specifically medium-coarse sand of 0.15-0.5mm;

[0082] Described cement is specifically P.O42.5 ordinary portland cement;

[0083] The fly ash is Class II fly ash discharged from the pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com