A kind of sleeve grouting material for steel bar connection for prefabricated buildings

A sleeve grouting and assembly technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of hidden quality problems in the finished grouting material, achieve enhanced activation effect, reduce cost, and high activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

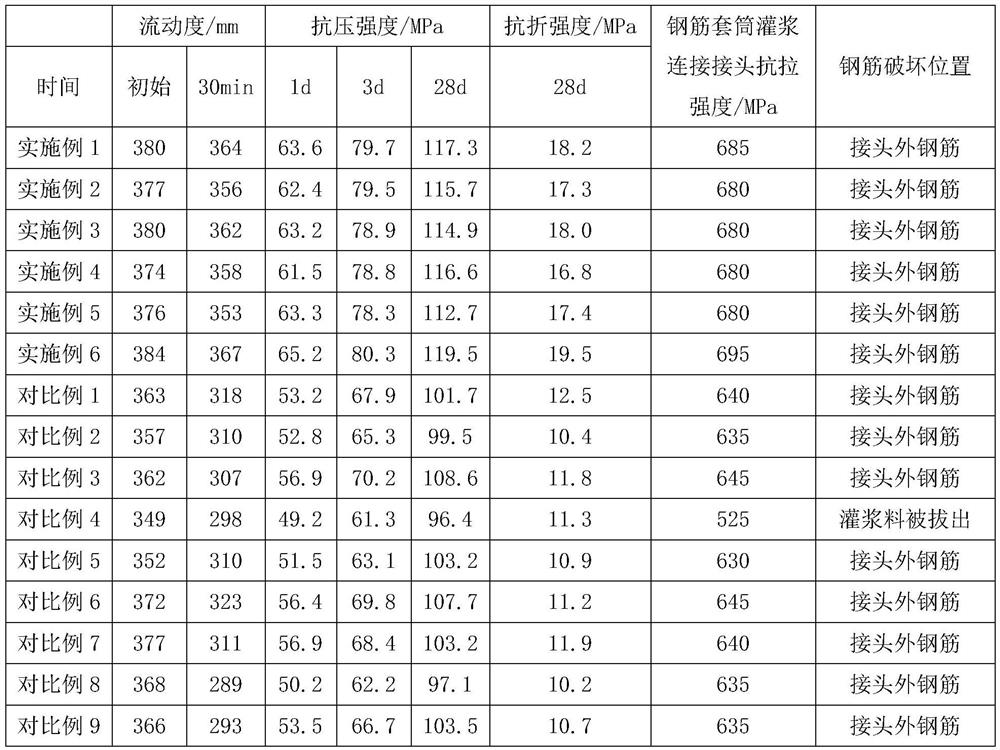

Examples

Embodiment 1

[0041] The sleeve grouting material provided in this embodiment includes the following components by weight: 820 parts of cement, 120 parts of waste concrete active micropowder, 950 parts of quartz sand, 60 parts of composite fiber, and 70 parts of admixture; wherein the waste concrete The active micro powder accounts for about 6% of the total amount of sleeve grout components.

Embodiment 2

[0043] The sleeve grouting material provided in this embodiment includes the following components by weight: 820 parts of cement, 100 parts of waste concrete active micropowder, 950 parts of quartz sand, 60 parts of composite fiber, and 70 parts of admixture; that is, the waste concrete The active micropowder accounts for 5% of the total amount of sleeve grout components.

Embodiment 3

[0045] The sleeve grout provided in this embodiment includes the following components by weight: 820 parts of cement, 143 parts of waste concrete active micropowder, 950 parts of quartz sand, 60 parts of composite fiber, and 70 parts of admixture; that is, the waste concrete The active micro powder accounts for about 7% of the total amount of sleeve grout components.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com