Preparation method and application of an aqueous room temperature phosphorescent carbon dot material

A room-temperature phosphorescence and carbon dot technology, which is applied to luminescent materials, material analysis and application through optical means, can solve the problems of ineffective dispersion and disappearance, and the particle size of carbon dot materials is prone to sedimentation, so as to achieve universal applicability , low cost and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045]Weigh 2g of potassium nitrate (melting temperature is 350°C), 0.2g of magnesium chloride, 0.1g of potassium dihydrogen phosphate and 0.05g of carbon source 1,2,4-triaminobenzene into a sample bottle, add 20ml of distilled water , fully stirred for 10 minutes to obtain a uniform solution, then vacuum freeze-dried, and obtained a uniform mixed powder after grinding. Put the powder in a crucible, raise the temperature to 400°C at a rate of 10°C in a muffle furnace, and keep it at 400°C for 4 hours, then cool it down to room temperature, and wash it with ultrapure water three times to remove the molten salt After drying in an oven, the carbon dot material with room temperature phosphorescence can be obtained.

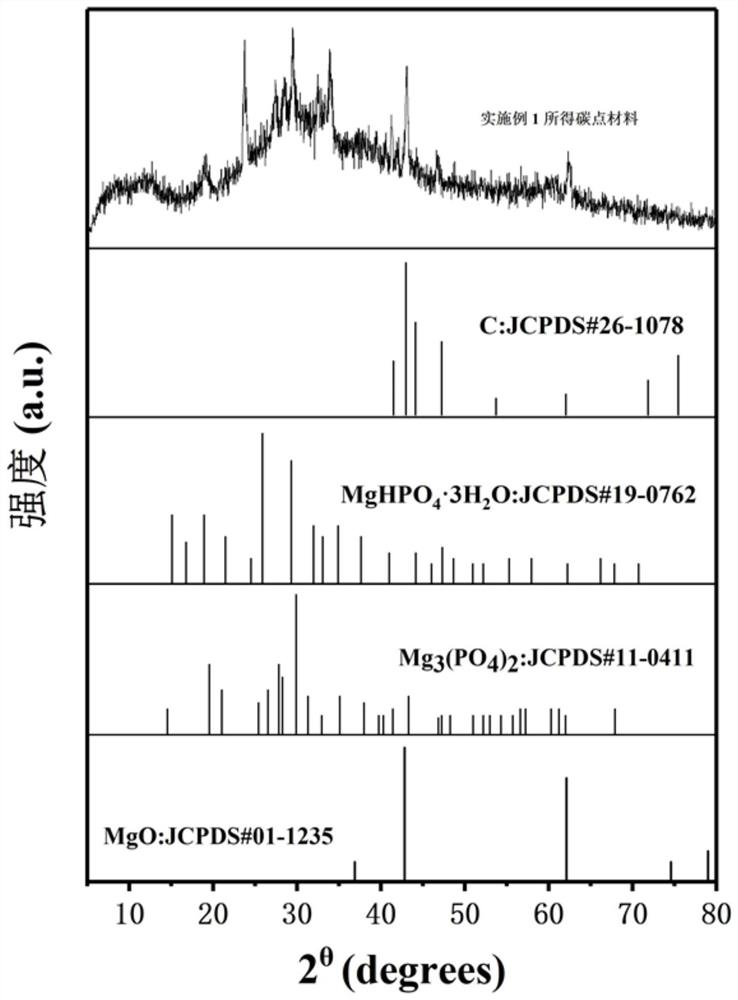

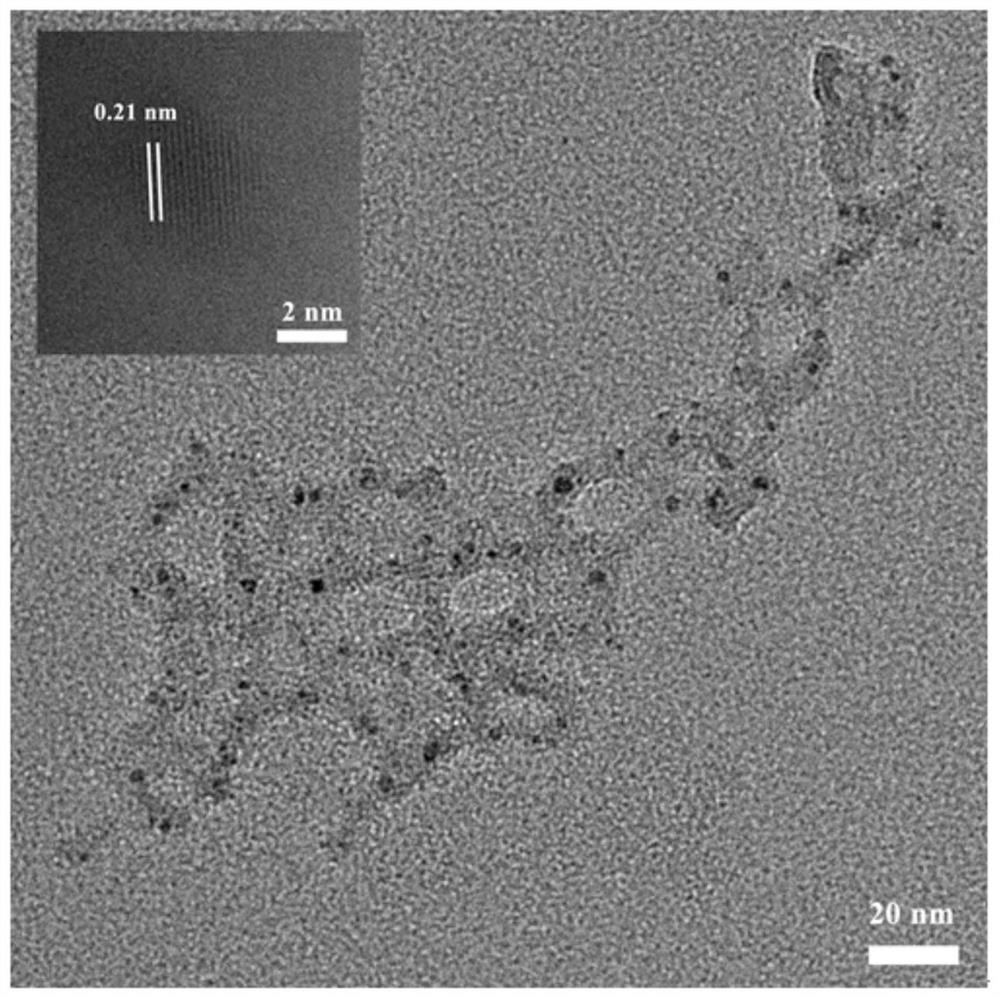

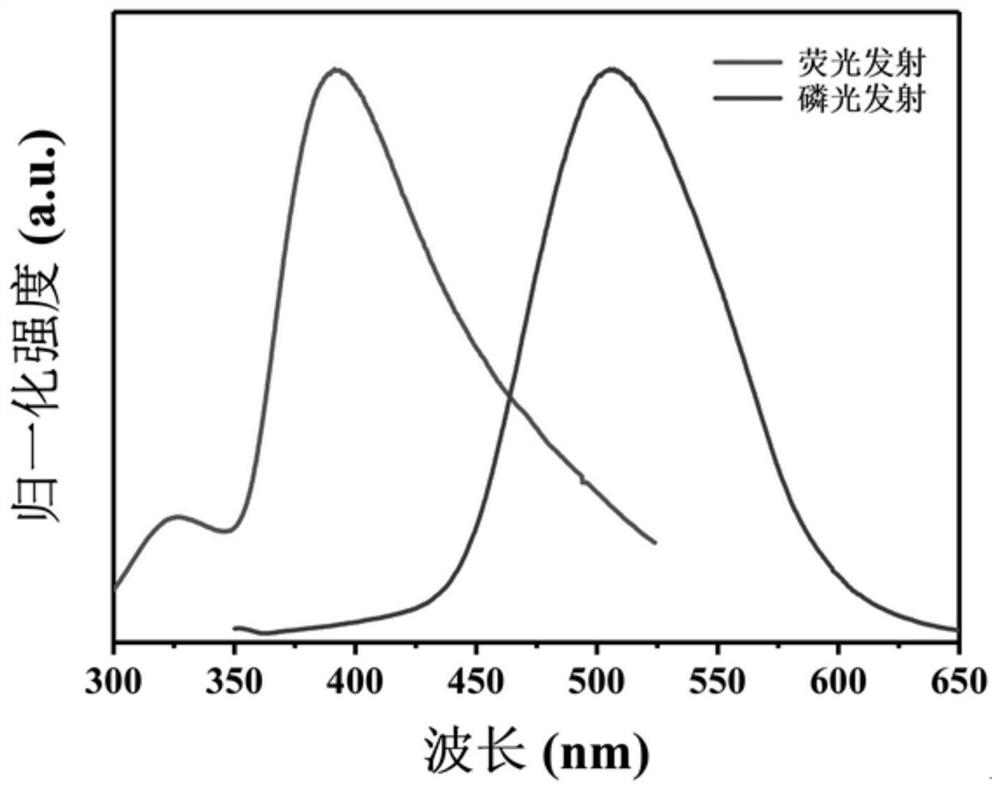

[0046] The morphology and structural composition of the carbon dot composites were analyzed by powder X-ray diffractometer and transmission electron microscope. The result is as figure 1 As shown, the XRD pattern of the carbon dot composite shows that there may be t...

Embodiment 2

[0050] Weigh 2g of sodium nitrate (melting temperature is 320°C), 0.2g of barium chloride, 0.1g of potassium dihydrogen phosphate and 0.05g of carbon source 1,2,4-triaminobenzene in a sample bottle, add 20ml of distilled water, fully stirred for 10 minutes to obtain a uniform solution, then vacuum freeze-dried, and obtained a uniform mixed powder after grinding. Put the powder in a crucible, raise the temperature to 350°C at a rate of 10°C in a muffle furnace, and keep it at 350°C for 5 hours, then cool it down to room temperature, and wash it three times with ultrapure water to remove the molten salt After drying in an oven, the carbon dot material with room temperature phosphorescence can be obtained. The result is as Figure 12 As shown, the best fluorescence emission of the prepared material in the aqueous phase is at 498nm, and the best phosphorescence emission is at 517nm (the optimum excitation wavelength is 400nm). The powder is white under the fluorescent lamp. Unde...

Embodiment 3

[0053] Weigh 2g of potassium nitrate (melting temperature is 350°C), 0.2g of strontium chloride and 0.05g of carbon source 1,2,4-triaminobenzene into a sample bottle, add 20ml of distilled water, stir well for 10min to obtain a uniform The solution is then vacuum freeze-dried, and a uniform mixed powder is obtained after grinding. Put the powder in a crucible, raise the temperature to 400°C at a rate of 10°C in a muffle furnace, and keep it at 400°C for 4 hours, then cool it down to room temperature, and wash it with ultrapure water three times to remove the molten salt After drying in an oven, the carbon dot material with room temperature phosphorescence can be obtained. The result is as Figure 13 As shown, the best emission of fluorescence of the prepared material is at 372nm, and the best emission of phosphorescence is at 509nm (the best excitation wavelength is 365nm). It is light yellow powder under fluorescent lamp, and the obtained powder exhibits blue fluorescence u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com