Hull for water surface garbage collection

A water surface garbage and hull technology, which is applied to the cleaning of open water surfaces, special-purpose vessels, water conservancy projects, etc., can solve the problems of increased garbage recycling costs, increased equipment costs, and long time required to achieve high garbage collection efficiency and production The effect of low cost and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

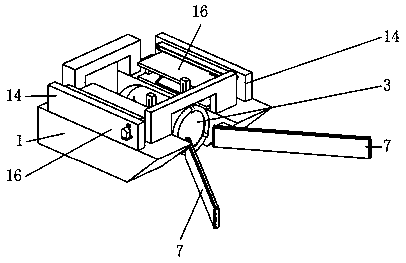

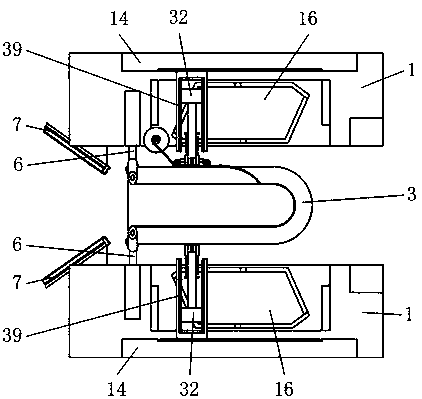

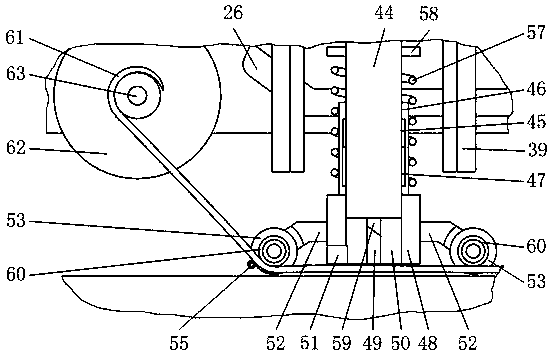

[0047] Such as figure 1 , 2 As shown, it comprises hull 1, support ring 2, mesh bag 3, support cover 4, draws back mechanism 7, heating closing mechanism 16, winding wheel 62, connecting rope 61, wherein as Figure 6 , 8 , 19, the hull 1 is a two-body type, and the space in the middle of the hull 1 is supported by three support sleeves 4 with a support ring 2, and the support sleeve 4 is nested on the support ring 2 and is rotatably matched with the support ring 2; Figure 6 , 18 As shown, there is a net bag 3 with one end sealing wound on the support ring 2; as figure 1 , 2 As shown, the front end of the hull 1 is symmetrically equipped with two retracting mechanisms 7 that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com