Pile foundation structure and construction method thereof

A construction method and pile foundation technology, which can be applied to foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of low concrete strength of the pile body, long construction period of cast-in-place piles, and low bearing capacity of single piles, etc. Restricted by the site, the effect of simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

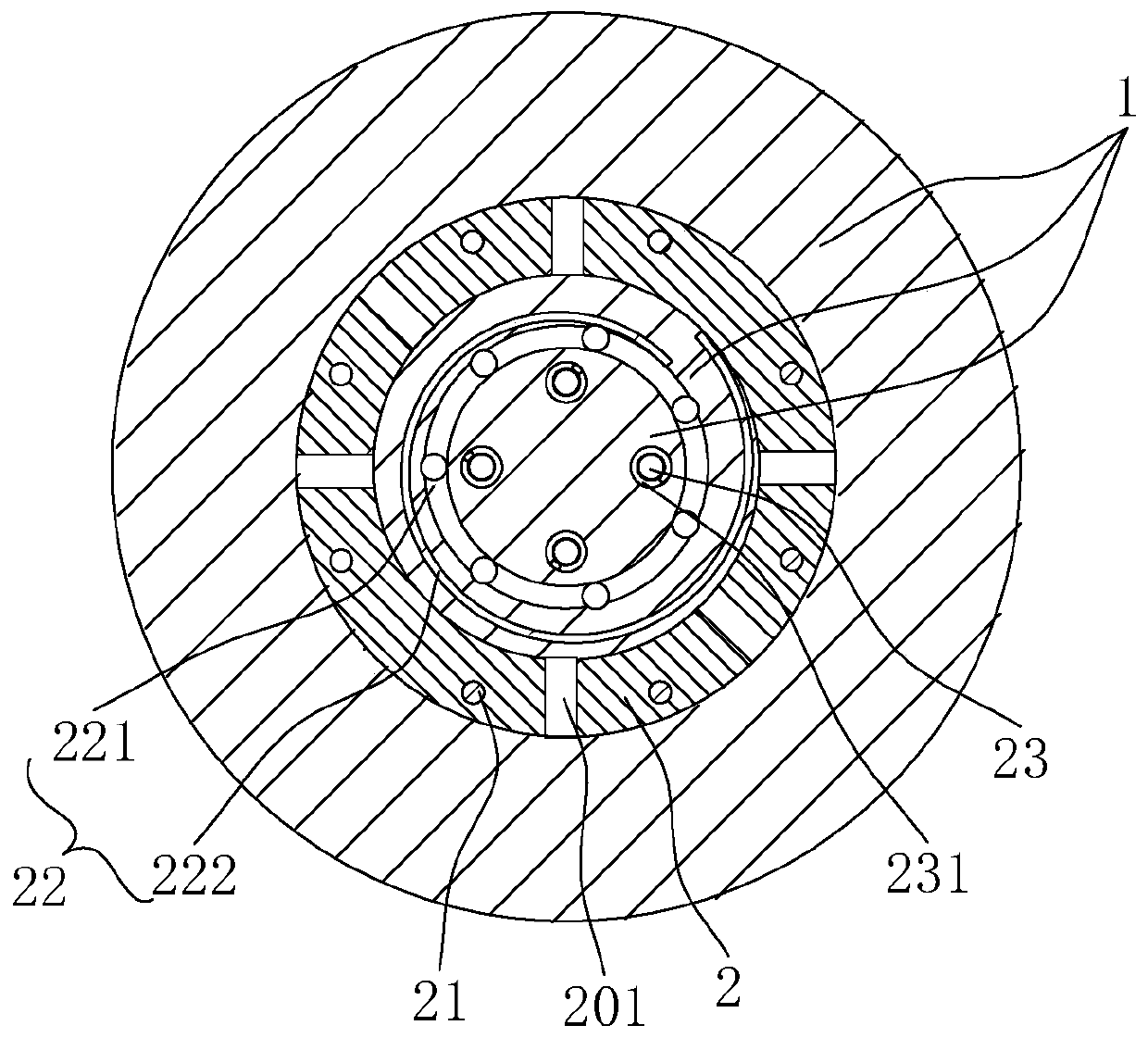

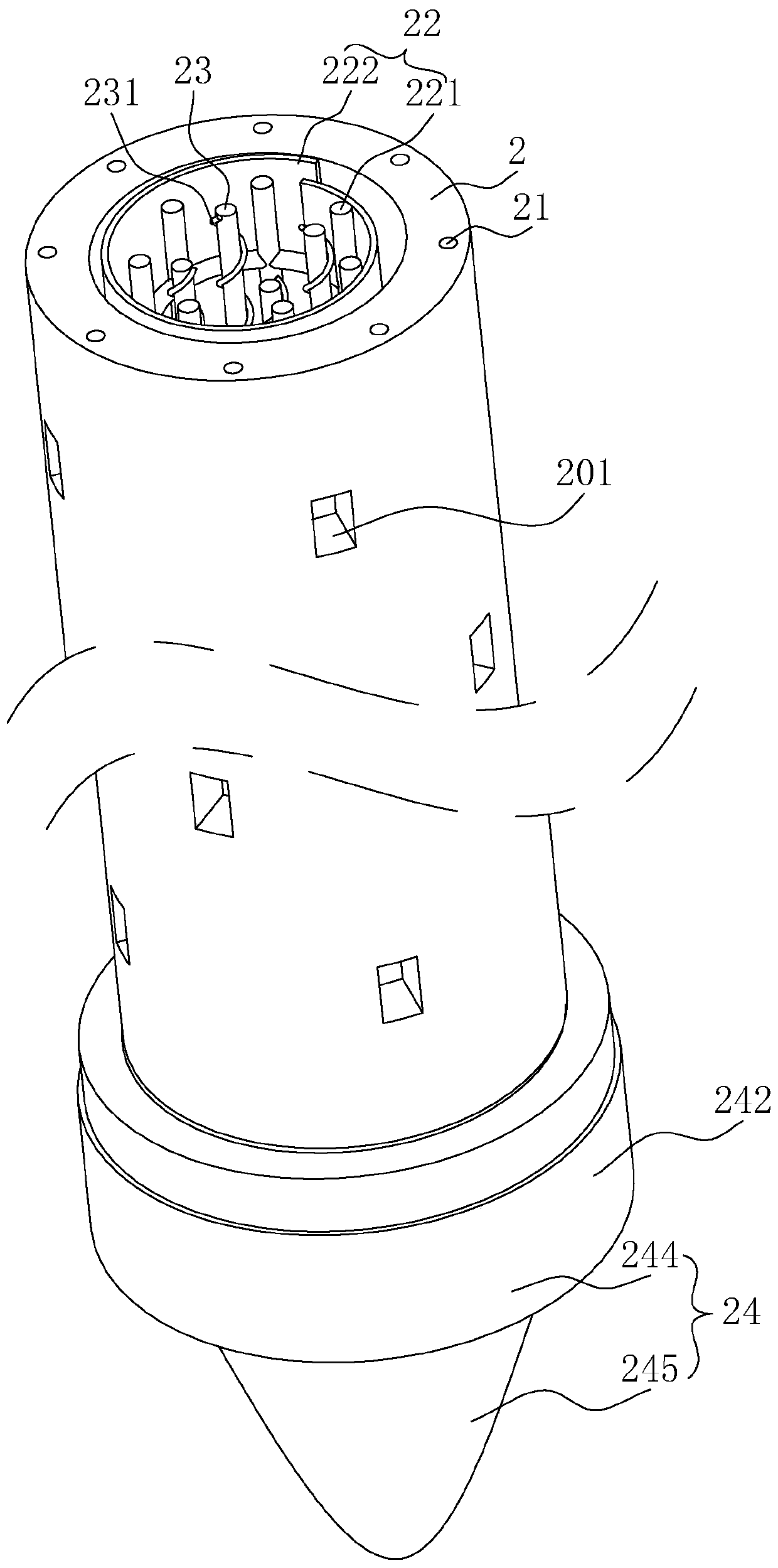

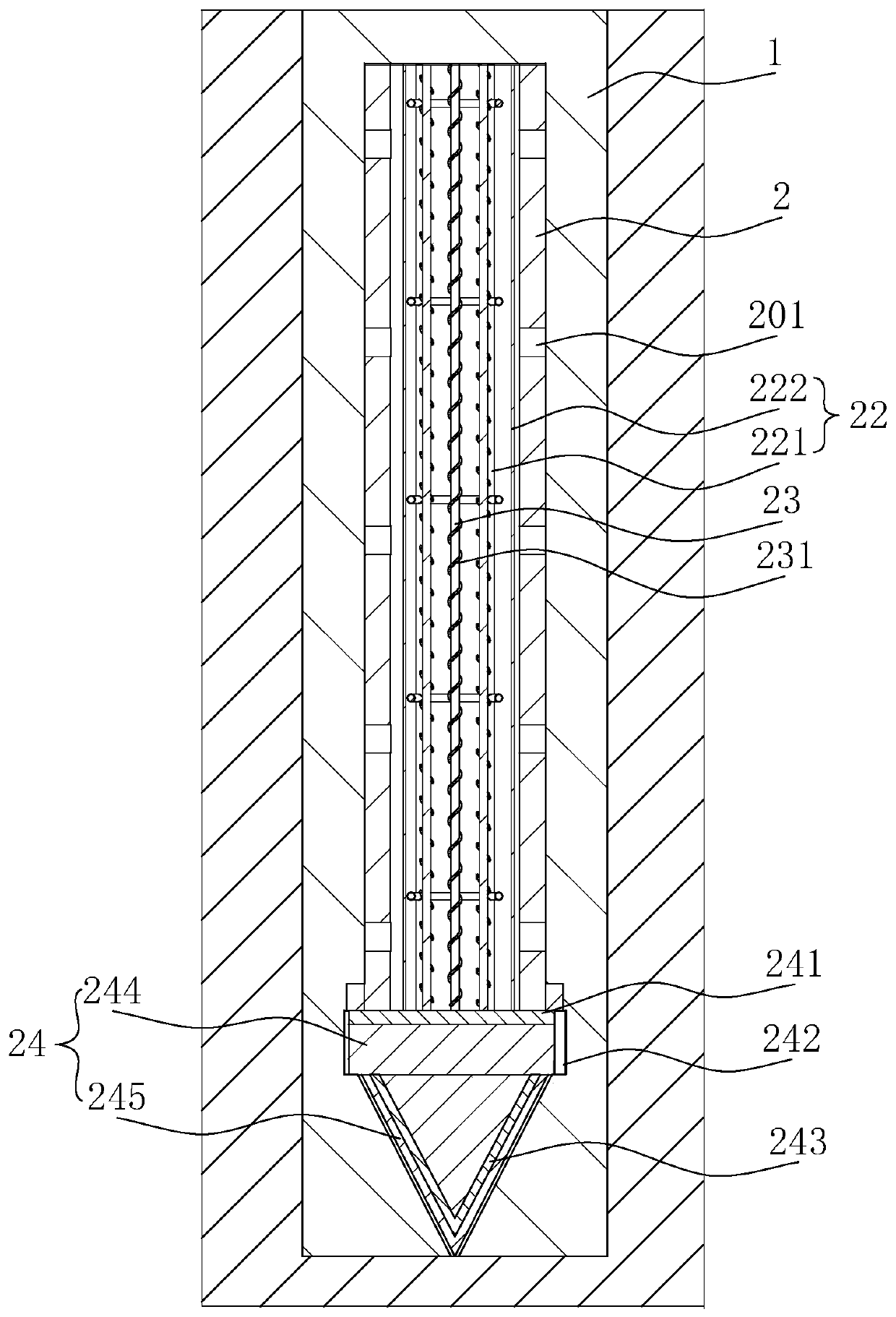

[0044] refer to figure 1 , figure 2 , a pile foundation structure, including cast-in-place pile 1, cast-in-place pile 1 is formed by pouring grout, and can be fixed with borehole pouring according to the shape of the borehole on the soil. The cast-in-situ pile 1 is embedded with a prefabricated pile core 2, and the prefabricated pile core 2 is set in the cast-in-place pile 1, which can increase the structural strength of the cast-in-place pile 1, and at the same time, the cast-in-situ pile 1 can shorten the curing time and shorten the construction period of the pile foundation; the prefabricated pile core 2 is provided with a cavity inside, and the prefabricated pile core 2 is provided with a steel frame 22 inside the cavity, and the steel frame 22 can play an internal support and reinforcement role for the pile foundation, making the structure of the pile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com