Centrifugal compressor and air blower driven by high-speed motor

A technology of centrifugal compressors and high-speed motors, applied in the direction of machines/engines, mechanical equipment, non-variable pumps, etc., can solve problems such as poor efficiency, achieve the effects of preventing heating, improving efficiency, and fully outputting pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

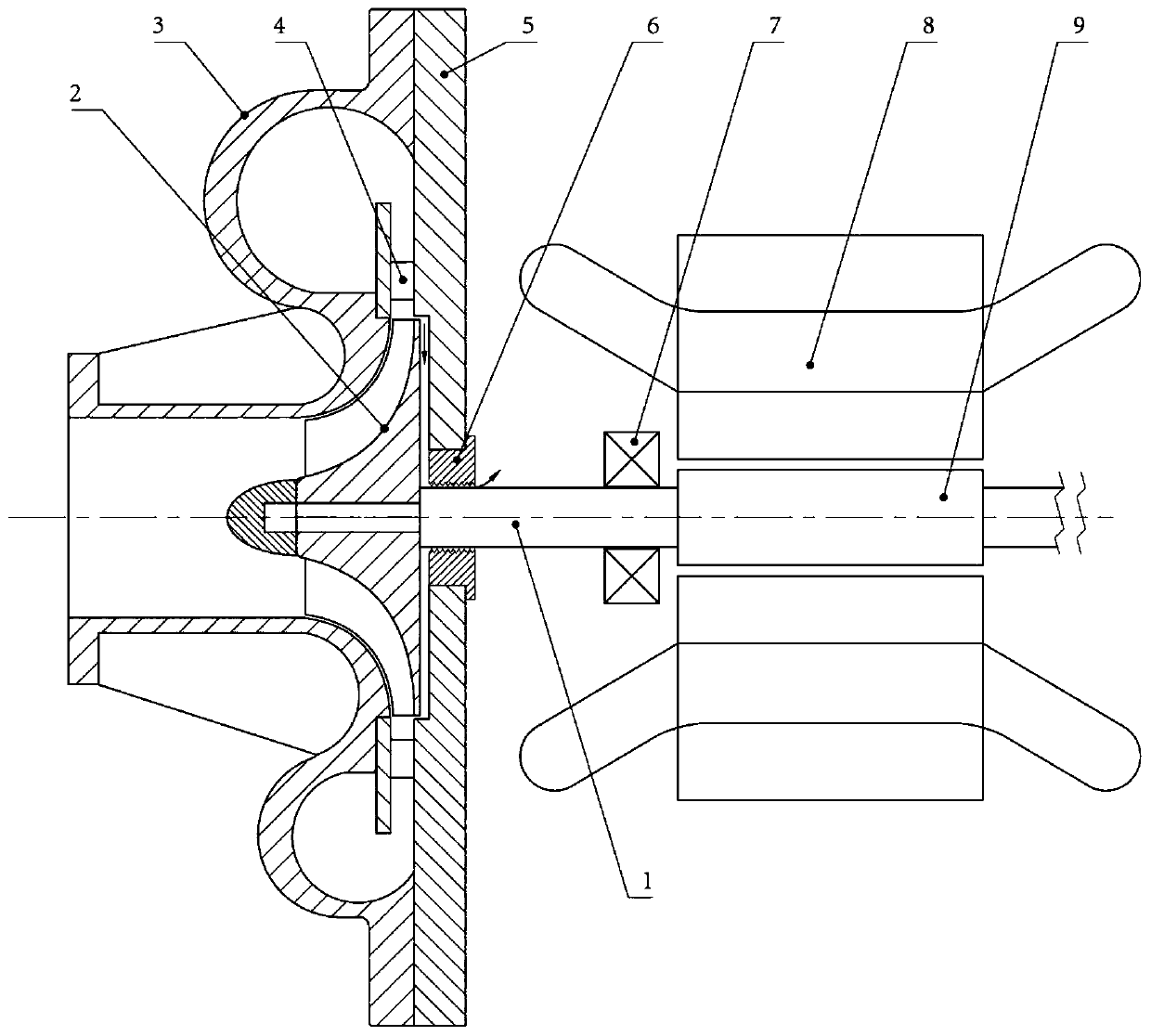

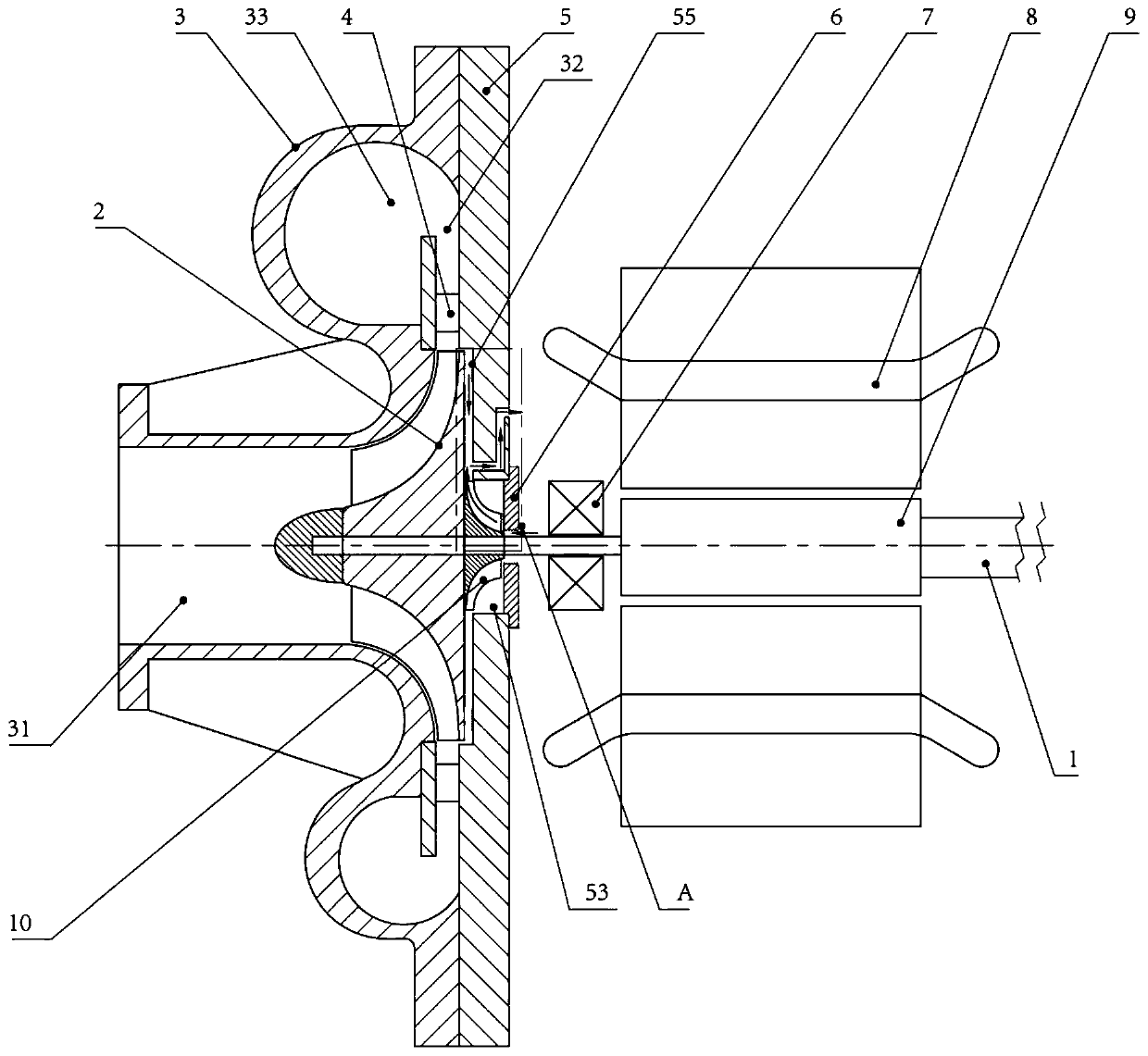

[0043] Combine below Figure 2-Figure 4 The first embodiment of the present invention will be described.

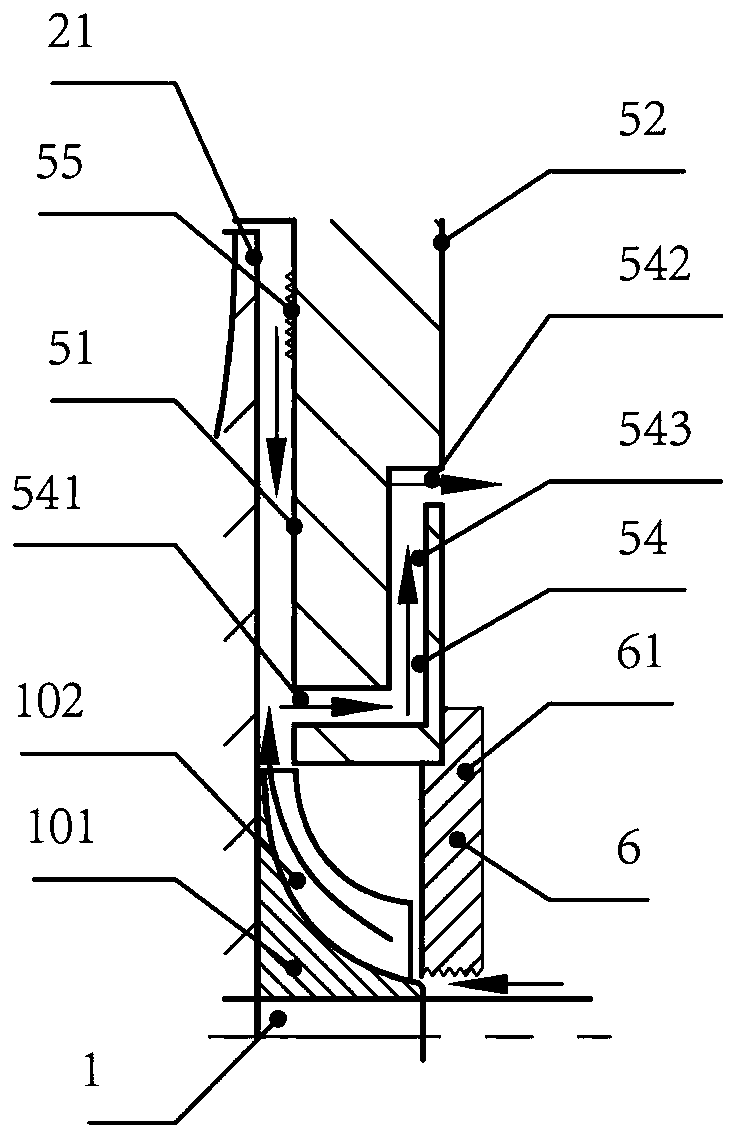

[0044] figure 2 A block diagram showing a centrifugal compressor according to a first embodiment of the present invention, image 3 show figure 2 The enlarged view of the structure in part A, Figure 4 A top view of the fin structure of the first embodiment is shown in .

[0045] Such as figure 2 and image 3 As shown, the present invention provides a centrifugal compressor, which includes a transmission shaft 1, an impeller 2, a volute 3, a diffuser 4, a back casing 5, a shaft seal 6, a bearing 7, a vane structure 10 and a high-speed motor.

[0046] The transmission shaft 1 passes through the through hole 53 opened in the center of the rear case 5 , and a shaft seal 6 such as a labyrinth seal is provided between the transmission shaft 1 and the rear case 5 . The other end of the shaft seal 6 has a flange portion 61 protruding radially outward over the entire c...

no. 2 approach

[0069] Combine below Figure 5-Figure 6 A second embodiment of the present invention will be described.

[0070] Figure 5 A block diagram of a centrifugal compressor according to a second embodiment of the present invention is shown in . Figure 6 A top view of the fin structure of the second embodiment is shown in .

[0071] In the second embodiment of the present invention, it is the same as the first embodiment except for the location where the fin structure 10' is installed and the shape and size are adjusted to suit the location. The same code|symbol is attached|subjected to the same part as 1st Embodiment.

[0072] In the second embodiment, the vane structure 10' is provided on the surface of the impeller 2 opposite to the first wall surface 51. The fin structure 10' includes a mounting plate 101' and a fin 102'. The center of the mounting plate 101' has a through hole 103' through which the transmission shaft 1 passes. The mounting plate 101' is installed on the ...

no. 3 approach

[0076] Combine below Figure 7-Figure 8 A third embodiment of the present invention will be described.

[0077] Figure 7 shows a configuration diagram of a centrifugal compressor according to a third embodiment of the present invention, Figure 8 A top view of an airfoil structure of a third embodiment is shown in .

[0078] The third embodiment of the present invention is the same as the first embodiment except for the location and shape of the fin structure 10 ″ and the shaft seal 6 ″. The same code|symbol is attached|subjected to the same part as 1st Embodiment.

[0079] In the third embodiment, the shaft seal 6" only needs to block most of the gap between the back casing 5 and the transmission shaft 1, and there is a seal between the shaft seal 6" and the transmission shaft 1 that is the same as that of the first embodiment. way and the larger gap compared to the second embodiment. The fin structure 10" is arranged on the part of the transmission shaft 1 opposite to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com