Rotary cylinder model test device

A model test device and cylinder technology, which is applied in the direction of measuring device, aerodynamic test, machine/structural component test, etc., can solve the problems such as difficult to meet the demand of speed, reduce test cost, increase stiffness, and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

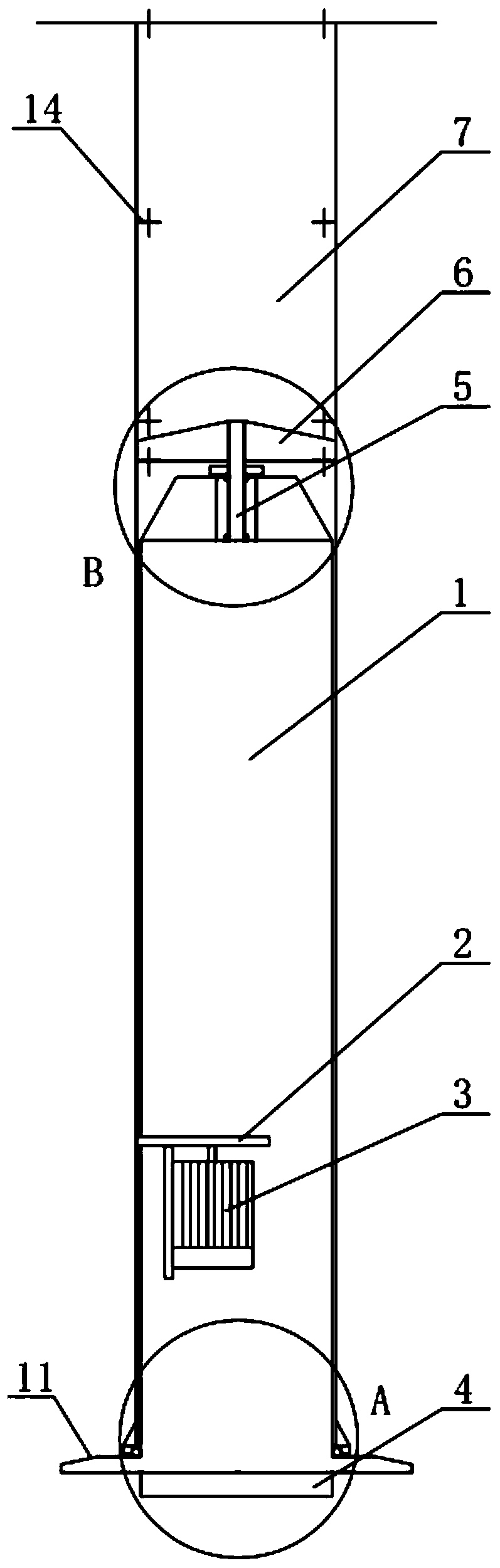

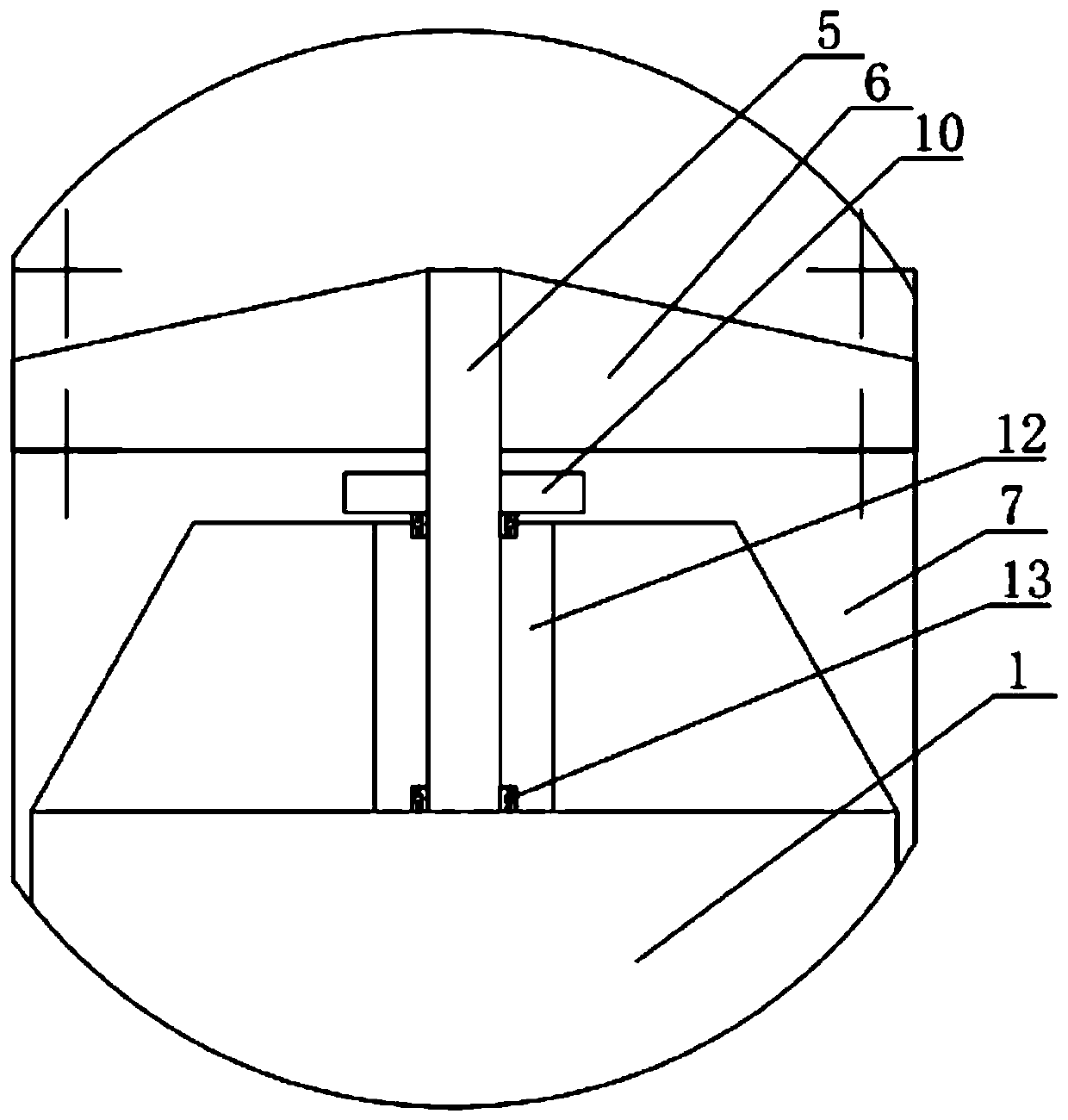

[0040] The support tower 1 is accommodated inside the cylinder 7, and there is a gap between the outer circumference of the support tower 1 and the inner wall of the cylinder 7; a large bearing is installed between the lower part of the circumference of the support tower 1 and the cylinder 7.

[0041] The large bearing is an angular contact ball bearing, which is installed between the inner wall of the cylinder 7 and the outer wall of the support tower 1; the outer ring of the angular contact ball bearing is fixed to the inner wall of the cylinder 7, and the angular contact ball bearing The inner ring is fixed to the outer wall of the support tower 1; the angular contact ball bearing provides the cylinder 7 with circumferential constraints and fulcrums relative to the support tower 1.

Embodiment 2

[0043] The support tower 1 is accommodated inside the cylinder 7, and there is a gap between the outer circumference of the support tower 1 and the inner wall of the cylinder 7; a large bearing is installed between the lower part of the circumference of the support tower 1 and the cylinder 7.

[0044] A base 11 extends from the bottom of the supporting tower 1 in the circumferential direction, and the diameter of the base 11 is larger than that of the supporting tower 1 and the cylinder 7 .

[0045] The large bearing is a thrust bearing, and the thrust bearing is installed between the bottom surface of the cylinder 7 and the base 11 of the support tower 1; Fixed installation; the thrust bearing provides the cylinder 7 with circumferential restraint and fulcrum relative to the support tower 1 .

Embodiment 3

[0047] The support tower 1 is accommodated inside the cylinder 7, and there is a gap between the outer peripheral surface of the support tower 1 and the inner wall of the cylinder 7; a ball mechanism is installed between the lower part of the peripheral surface of the support tower 1 and the cylinder 7.

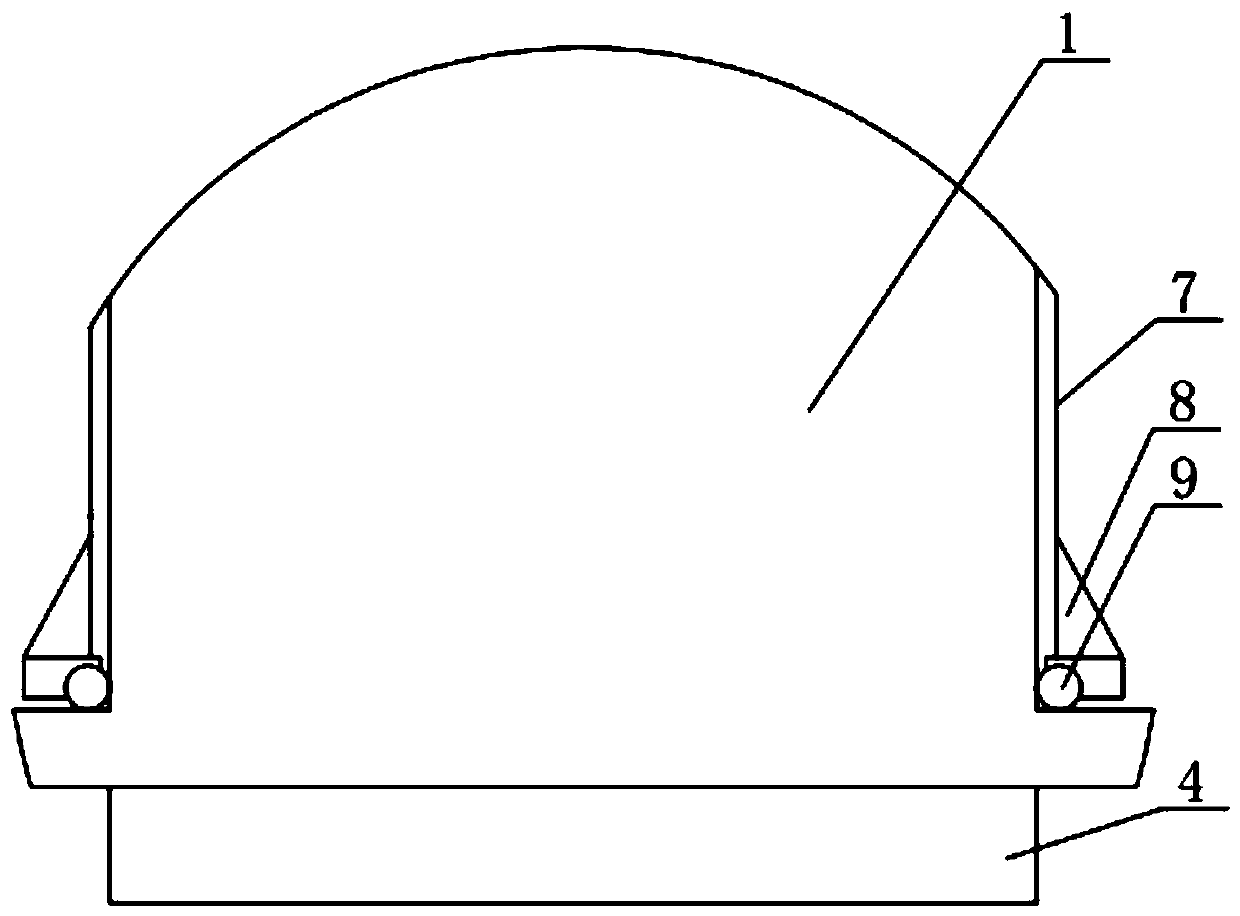

[0048] The bottom of the support tower 1 extends toward the circumferential direction with a base 11, and the diameter of the base 11 is greater than the diameter of the support tower 1 and the cylinder 7; as figure 2 As shown, the structure of the ball mechanism is as follows: it includes a bracket 8 installed circumferentially along the lower edge of the outer peripheral surface of the cylinder 7, and a plurality of balls 9 are installed circumferentially between the bracket 8 and the supporting tower 1; 9 is snapped into the corresponding hole on the bracket 8, and the single ball 9 rotates relative to the bracket 8; 1. The upper surface of the base 11 is in contact at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com