Solenoid

A technology of solenoids and coils, applied in the direction of transformers/inductor coils/windings/connections, transformers, electrical components, etc., can solve the problems of changing the space structure of the metal shell, unfavorable epoxy resin coating, and affecting the use of ignition coils, etc. , to achieve the effects of improving manufacturing quality, preventing movement, and stabilizing filling space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

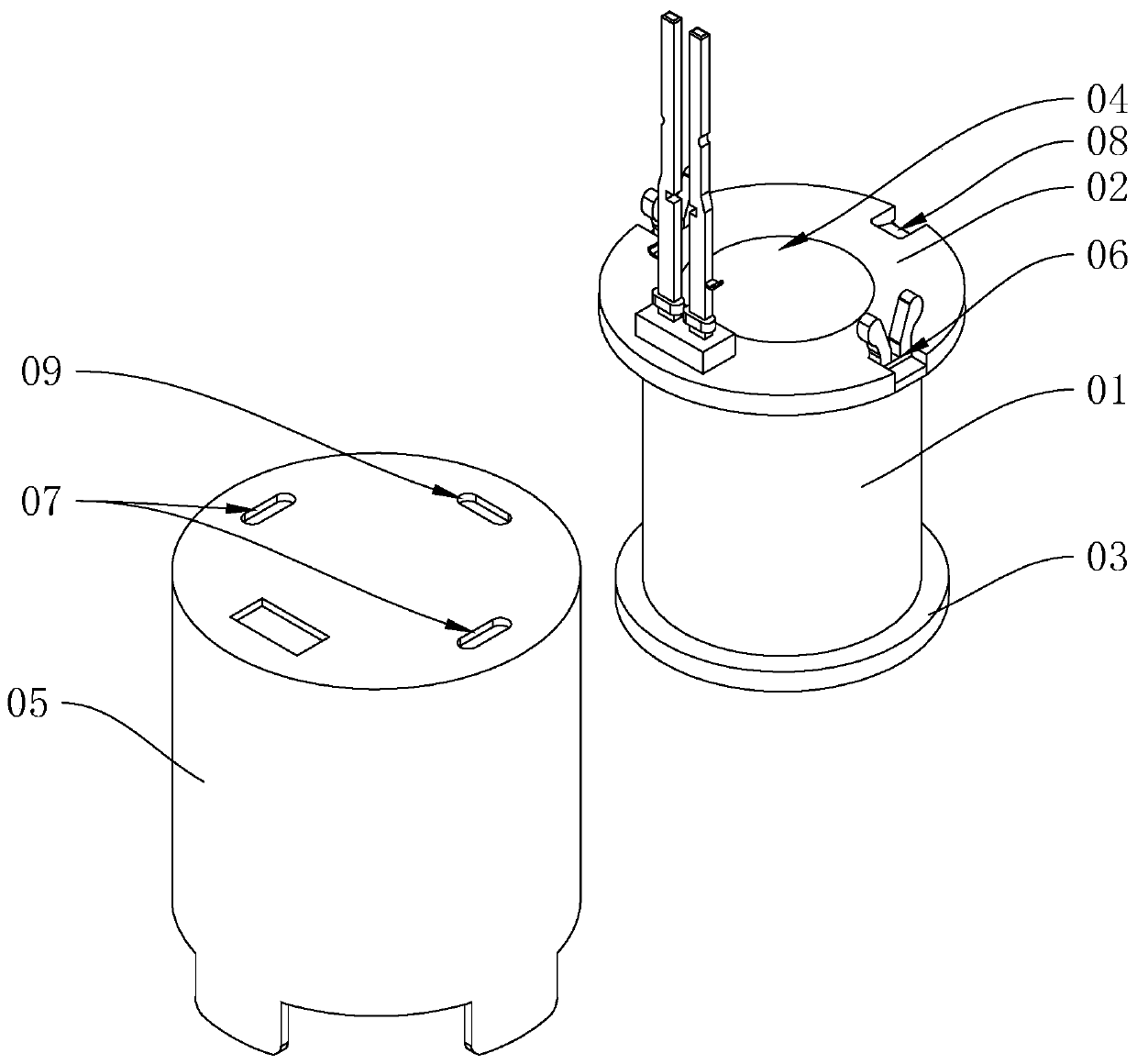

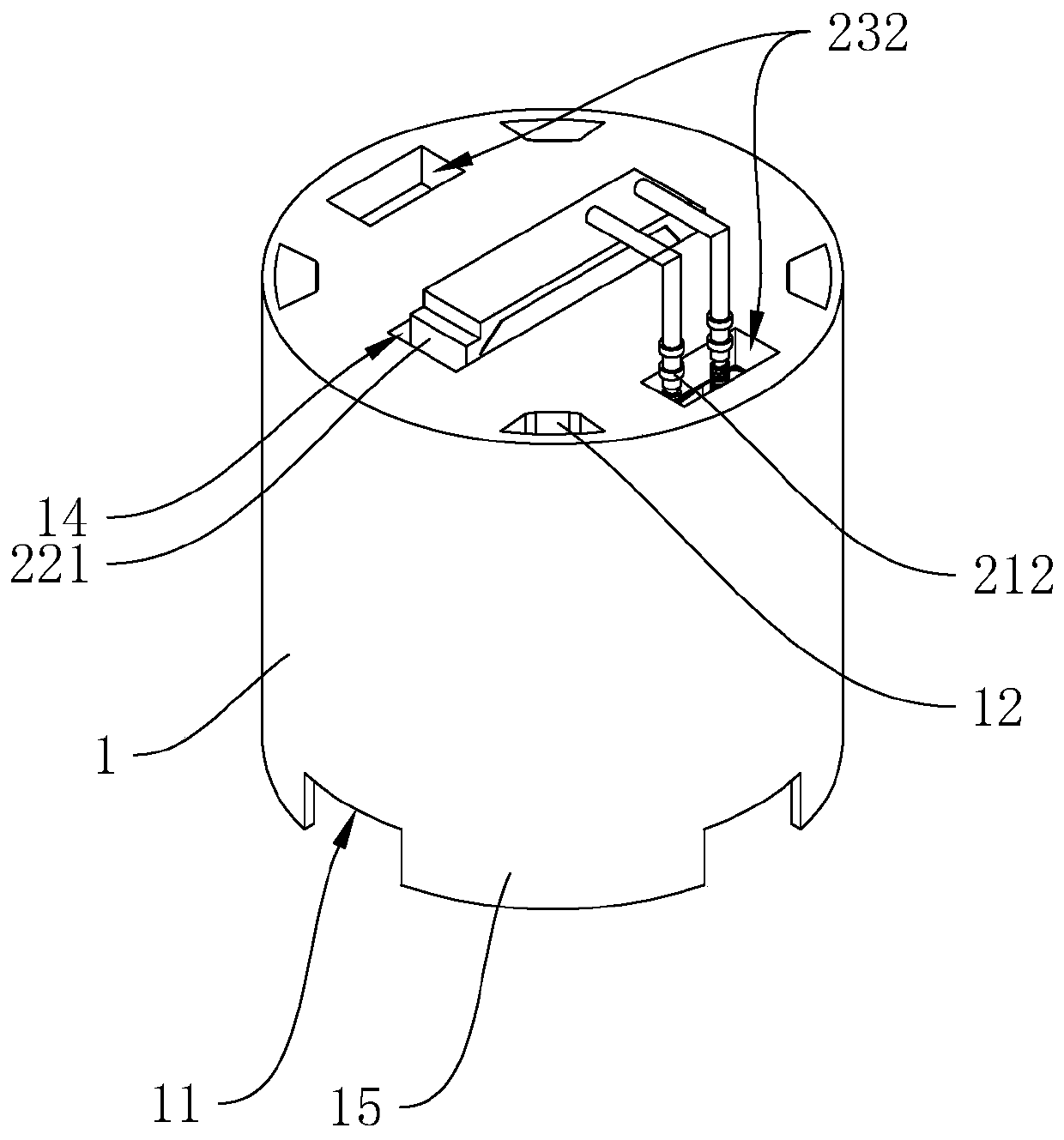

[0034] refer to figure 2 with image 3 , is a solenoid, including a cylindrical metal sleeve 1 and a cylinder frame 2, the metal sleeve 1 is a ferromagnetic sleeve body, and one end of the metal sleeve 1 is provided with an installation port 11 for installing the cylinder frame 2, and the installation port 11 Four bendable fixed pieces 15 are extended along the axial direction of the metal; the metal sleeve 1 is provided with two filling ports 13 and a plug hole 14 on the end surface of the metal sleeve 1 away from the installation port 11, and on the outer side of the metal sleeve 1 The four protrusions 12 obtained by internal stamping, the four protrusions 12 are located on the same circular contour coaxial with the metal sleeve 1 .

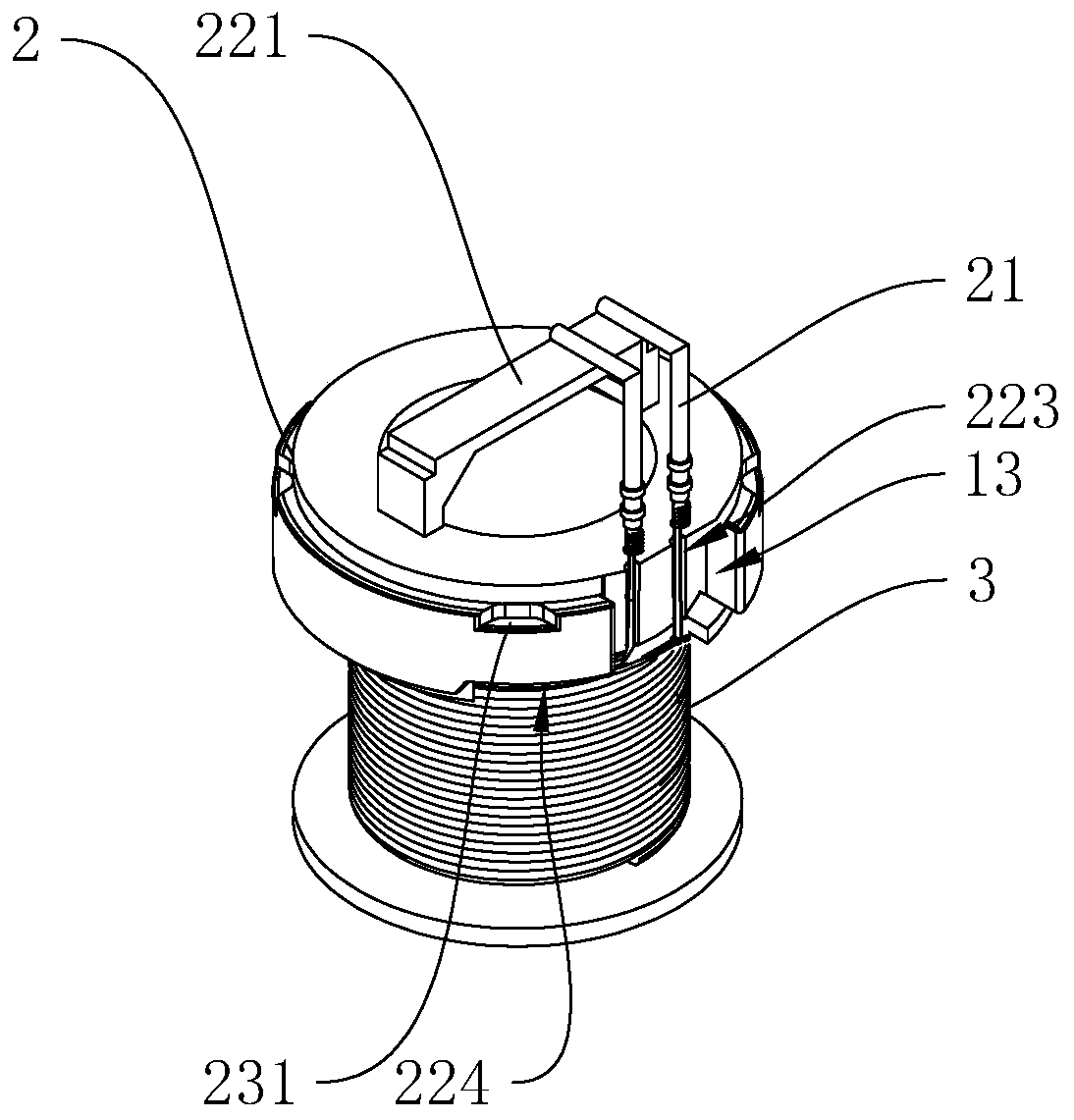

[0035] compare again image 3 with Figure 4 , the cylinder skeleton 2 includes a magnet ring 23, on the magnet ring 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com