Polluted soil remediation equipment based on ex-situ chemical leaching

A technology for chemical leaching and polluted soil, applied in the field of soil remediation, can solve the problems of reduced soil remediation efficiency, troublesome soil cleaning, and reduced soil remediation efficiency, and achieve the effect of improving spraying effect, improving contact efficiency, and efficient turning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

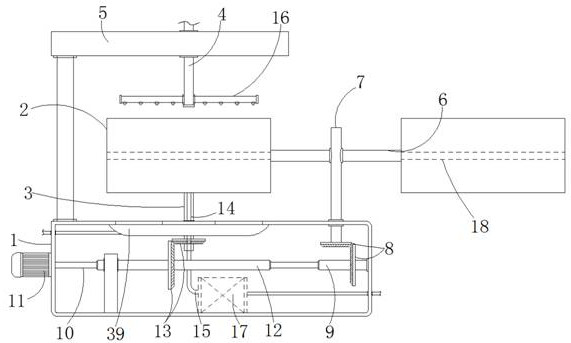

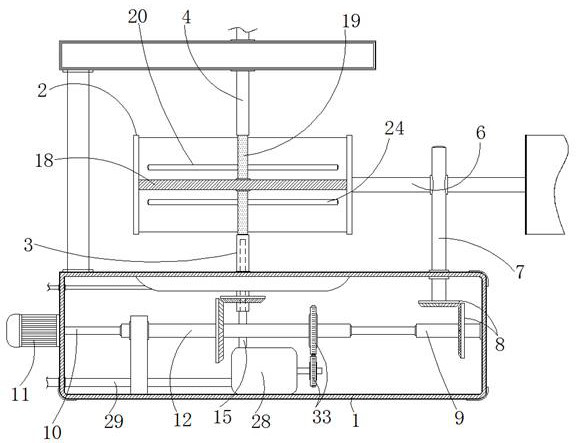

[0033] Such as figure 1 As shown, the restoration equipment includes a base 1 and a storage box 2, the storage box 2 is used to accommodate soil particles, the storage box 2 is located above the base 1, and the top of the storage box 2 is provided with a frame 5 installed on the upper end surface of the base 1, The bottom and top of the containing box 2 are respectively provided with a cleaning rod 3 and a spraying rod 4, and also includes a partition 18, which is horizontally fixed at the middle position inside the containing box 2, and the containing box 2 is evenly divided into upper and lower parts. The space for accommodating soil particles, and the accommodating box 2 is a structure with upper and lower openings, and the accommodating box 2 is installed on the upper half of the vertical axis 7 through the rotation of the horizontal axis 6, and the vertical axis 7 installed in the upper wall on the right side of the base 1 is rotated The bottom end is connected to the fir...

no. 2 example

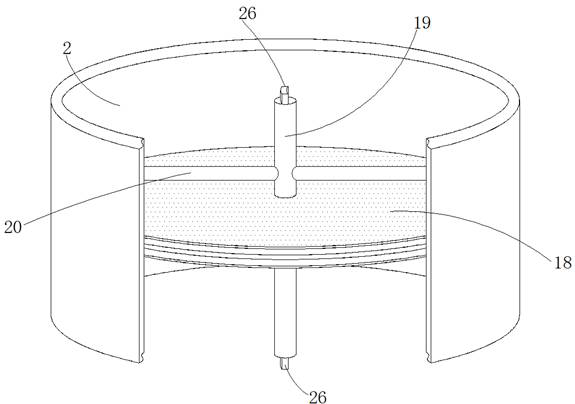

[0037] Different from the first embodiment, the sprinkler assembly in this embodiment includes a driving device and a sprinkler device, and the sprinkler device is composed of a core rod 19 and a first cross bar 20, and the core rod 19 is installed at the center of the dividing plate 18 , the vertically distributed core rod 19 and the horizontally distributed first cross bar 20 are respectively provided with a third cavity 23 and a second cavity 22 connected to each other, and the second cavity 22 and the lower end surface of the first cross bar 20 The spray hole 21 is connected, and the third cavity 23 is connected with the inner cavity of the spray rod 4, and the spray rod 4, which is rotatably installed on the frame 5, is connected with the water pipe at the output end of the water pump, and the water pump passes through the spray rod 4. The spray liquid is sprayed out through the third cavity 23, the second cavity 22 and the spray hole 21, and the wetting operation is perfo...

no. 3 example

[0041] As an additional technical solution in this application, in order to ensure that metal impurities that are not fully screened in the soil will not affect the subsequent backfilling of the soil, the separator 18 in this embodiment includes the outermost elastic layer 36, with Based on the reinforced filling layer 35 and the electromagnetic plate 34 located at the center, the electromagnetic plate 34 is energized to generate magnetism for absorbing unscreened metal particles mixed in the soil.

[0042] As a further step, in the filling layer 35 in this embodiment, there is also a slideway 37 that penetrates up and down. Be connected with magnetic block 38, and the surface corresponding to magnetic block 38 and the electromagnetic plate 34 after energization is mutually repulsive setting, when electromagnetic plate 34 carries out intermittent power on and off, as Figure 8 As shown, the magnetic block 38 will correspondingly slide in the slideway 37 at high frequency, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com