Basket conveying mechanism of cleaning machine

A technology of conveying mechanism and cleaning machine, which is applied in the direction of conveyor objects, transportation and packaging, cleaning methods and utensils, etc. It can solve the problems of affecting the production efficiency of processing enterprises, prolonging the time of cleaning operation, increasing the instability of the mechanism, etc., to achieve Speed up the cleaning process, save production resources, and improve the effect of mechanical relations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

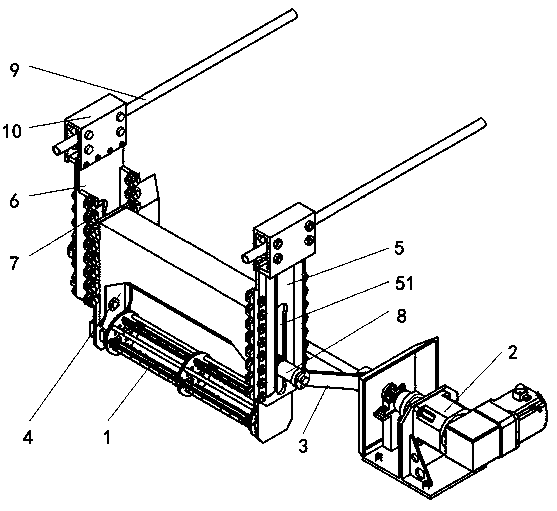

[0024] The invention discloses a washing machine flower basket conveying mechanism adapted to a two-tank semi-automatic washing machine, the details are as follows.

[0025] Such as figure 1 As shown, a washing machine flower basket transport mechanism is fixedly installed on an existing washing machine, and includes a flower basket 1 for carrying wafers to be cleaned and a driving assembly for driving the flower basket 1 to swing in a circumferential direction.

[0026] The washing machine flower basket delivery mechanism also includes a vertical limit assembly for limiting the vertical stroke of the flower basket 1 and a horizontal limit assembly for limiting the horizontal stroke of the flower basket 1. Both the vertical limiting components are movably connected, and the flower basket 1 is movably connected to the vertical limiting components. Under the cooperative action of both the horizontal limiting component and the vertical limiting component, the swing of the flower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com