Millet straw separator

A separator and separation mechanism technology, applied in the field of grain and straw separators, can solve problems such as low efficiency and low safety, and achieve the effects of improving product quality, productivity, and machine utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The implementation of the present invention will be described in detail below with examples, so as to fully understand and implement the implementation process of how the present invention uses technical means to solve technical problems and achieve technical effects.

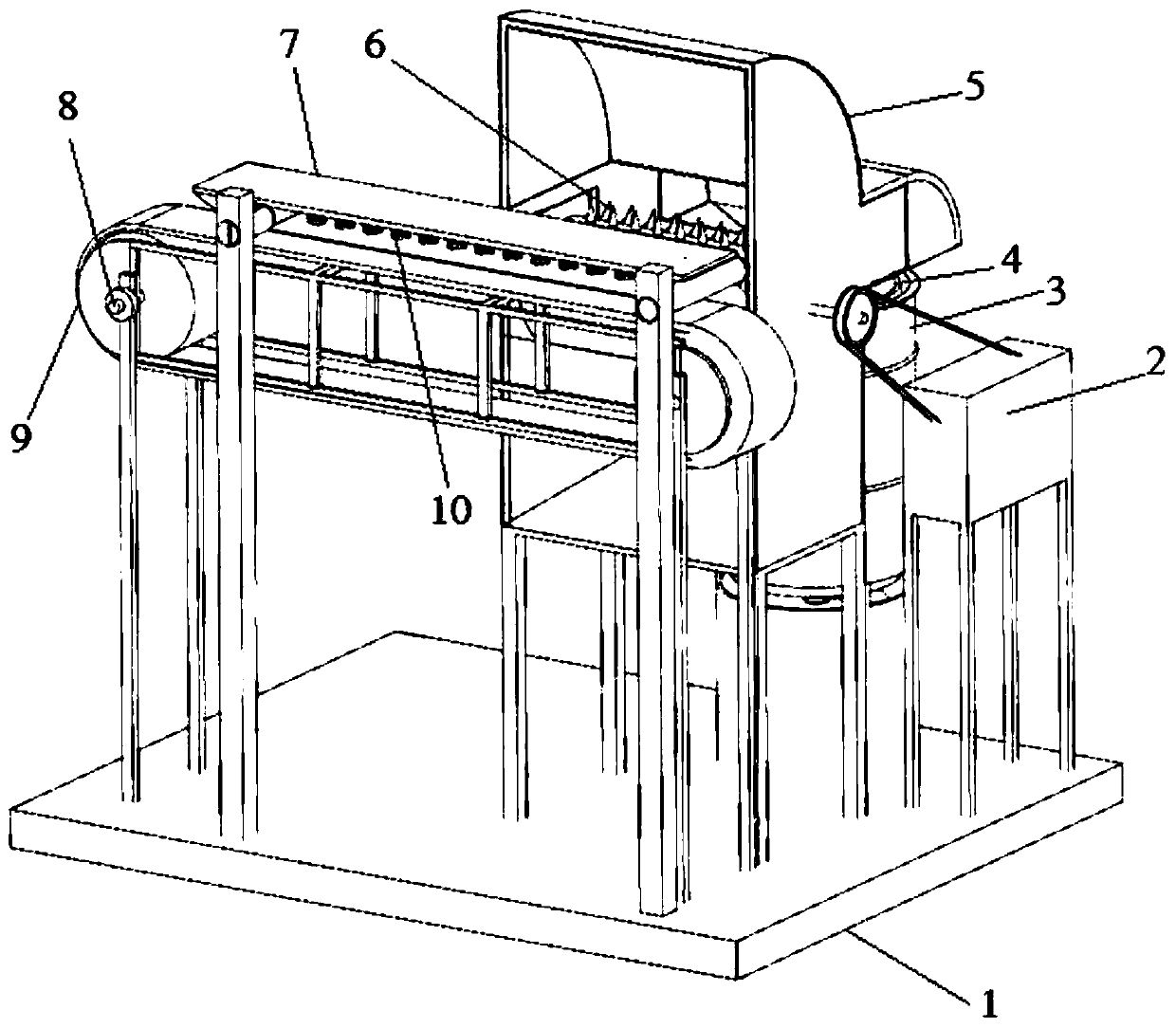

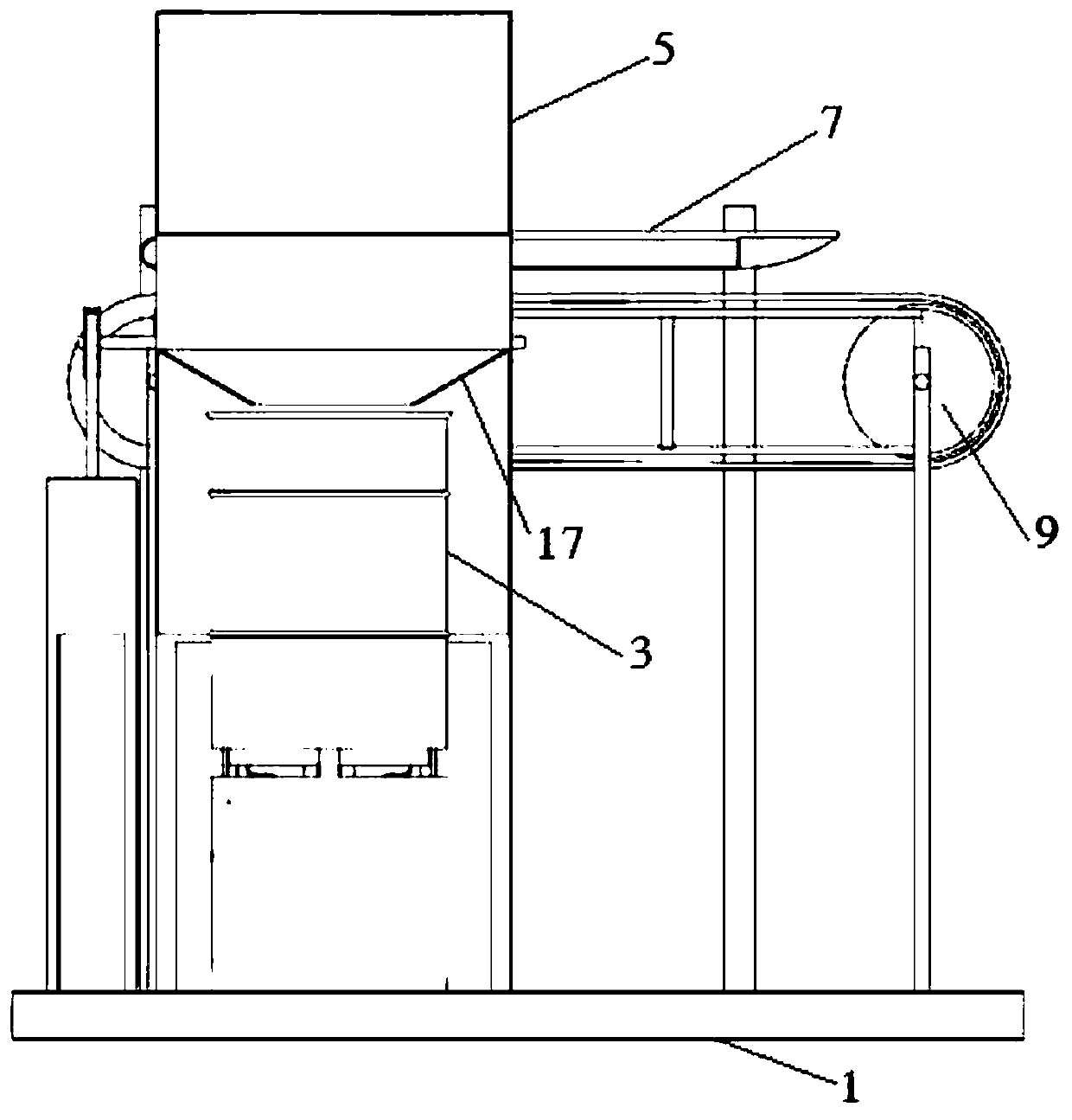

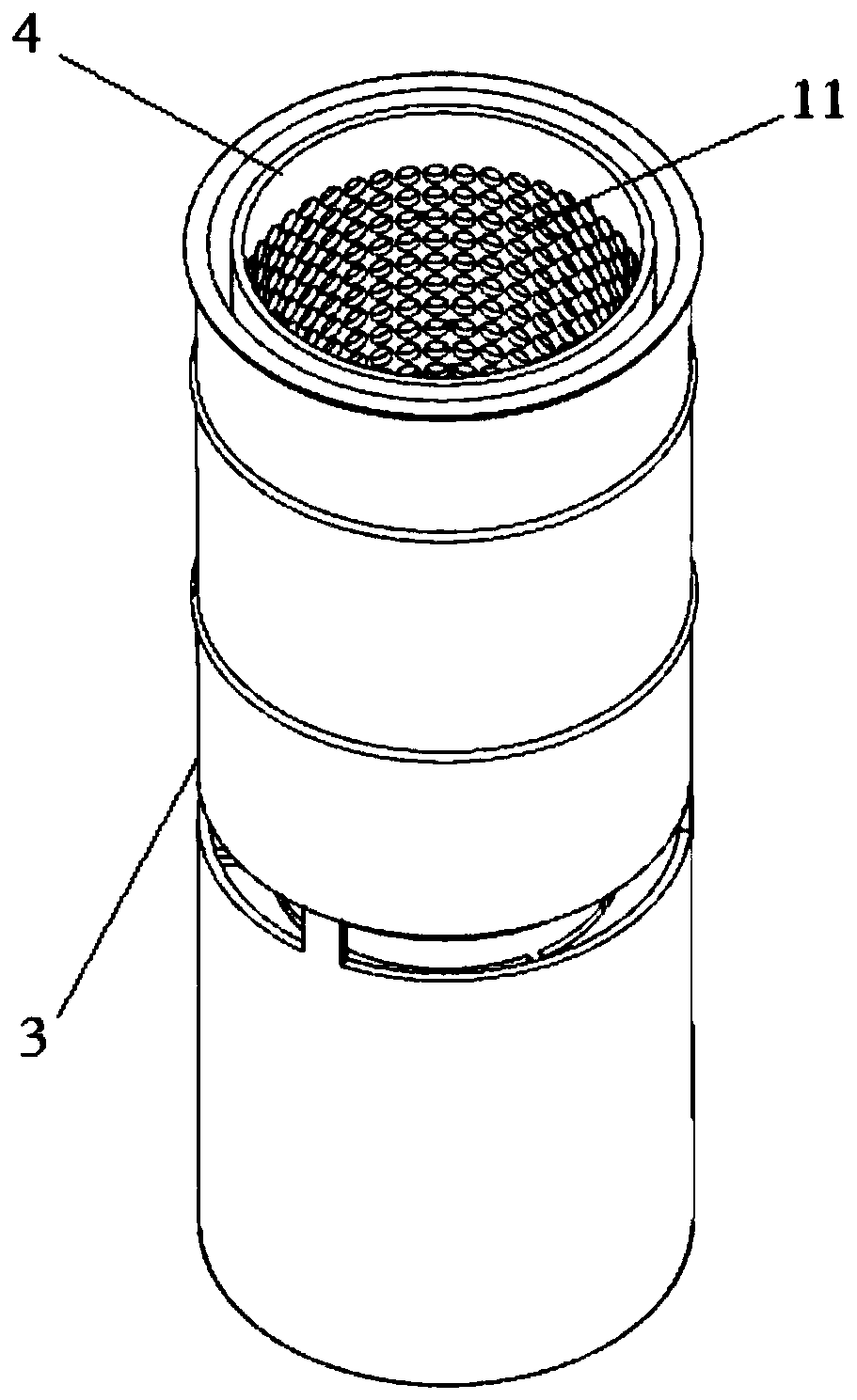

[0026] Such as figure 1 As shown, a kind of grain-grass separator of the present invention comprises frame 1, and frame 1 is provided with conveying mechanism and grain-stopping cover 5, and threshing roller 6 is rotatably arranged in the grain-stopping cover 5, and grain-stopping cover 5 The side of the drum separation mechanism is provided with a drum separation mechanism, the outside of the drum separation mechanism is provided with a grain collection cylinder 3, and the conveying mechanism is located at the side of the threshing roller 6.

[0027] When using the grain and grass separator of the present invention, the grain material is put into the conveying mechanism, and the grain material is transf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com