Material roller preparation arrangement

A material roll and component technology, which is applied in the removal of binding materials, thin material processing, and winding strips, etc., can solve problems such as high costs, and achieve high-quality functions, good operability, and reliable functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

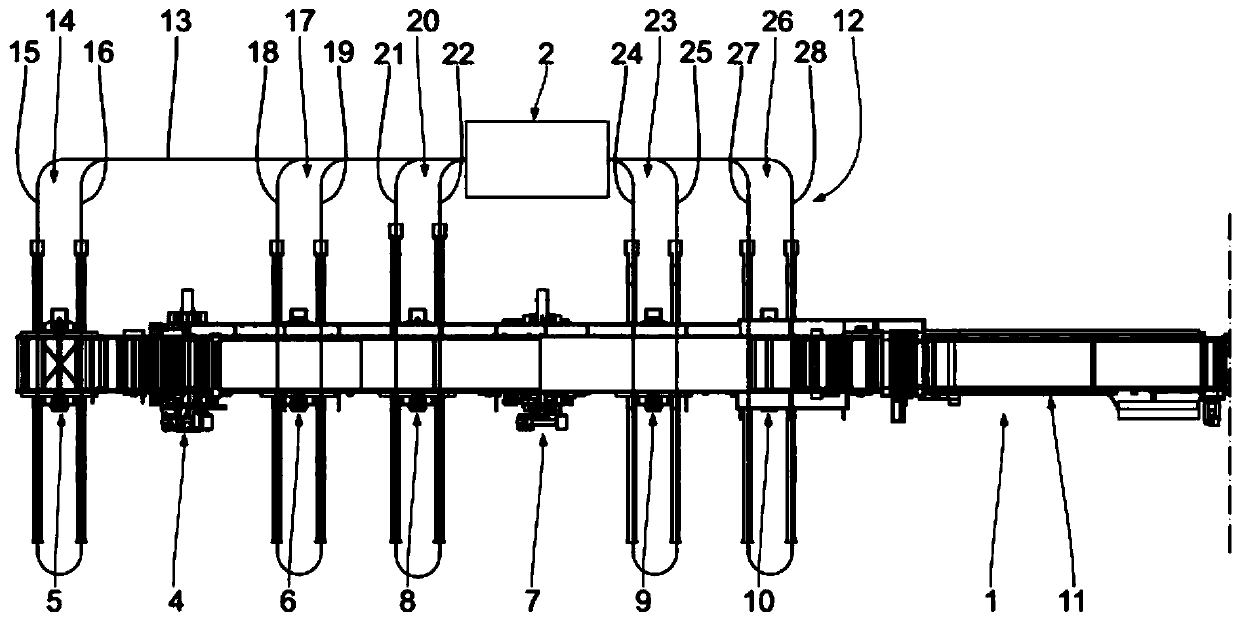

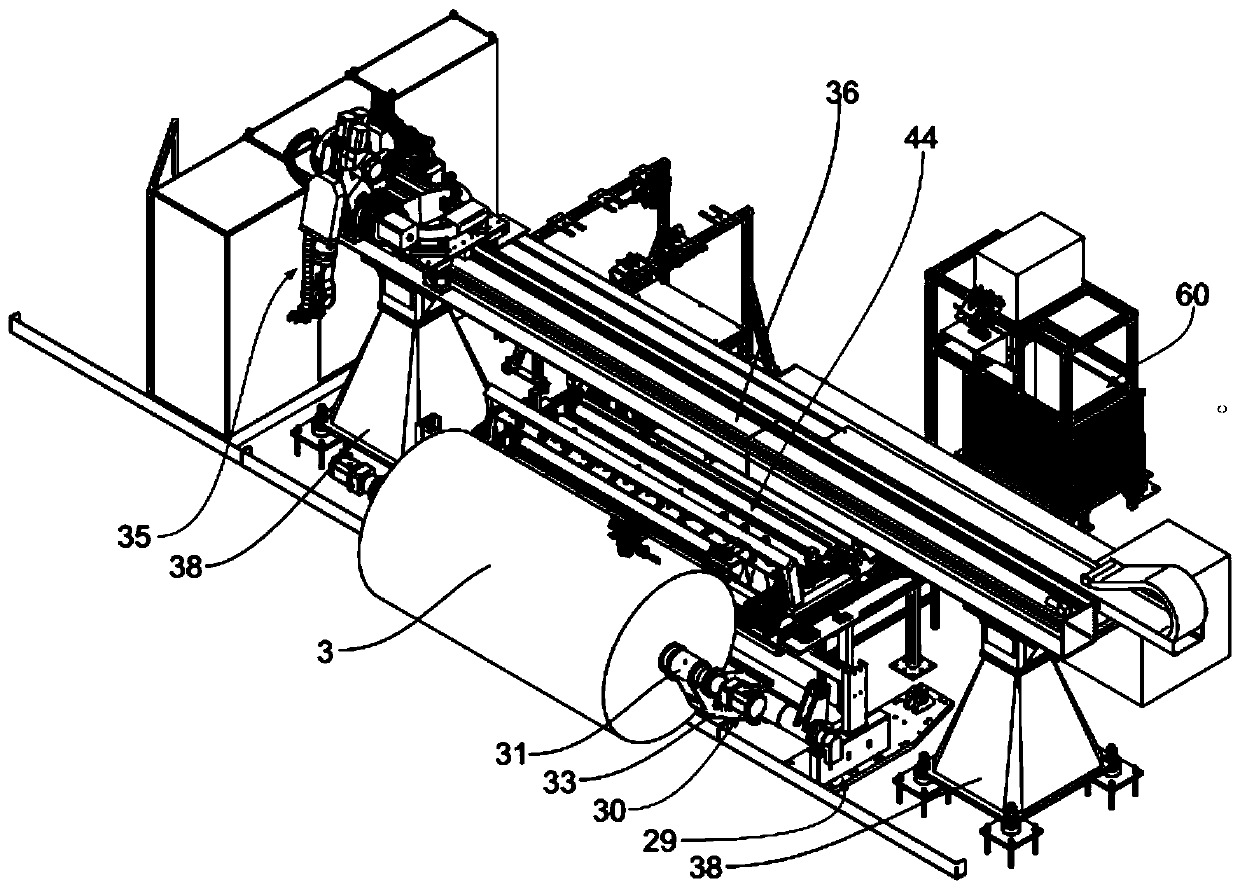

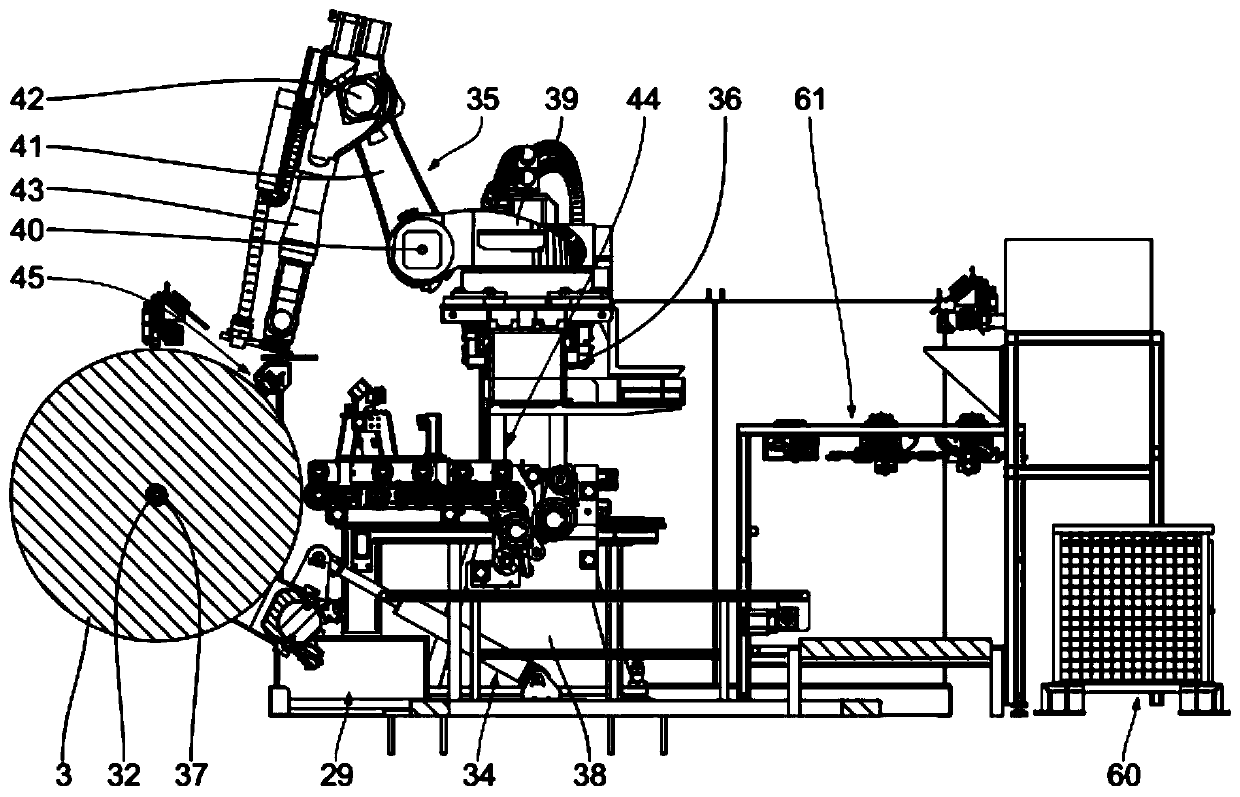

[0052] exist figure 1 The overall plant shown in its entirety in , comprises a corrugated cardboard plant 1 and exactly one roll preparation unit 2 arranged adjacent thereto for preparing a material roll 3 for use in the corrugated cardboard plant 1 .

[0053] The corrugated cardboard machine 1 extends linearly. The corrugated cardboard line has a first corrugated cardboard production device 4 for producing a first corrugated cardboard web laminated on one side. A first top web splicing device 5 and a first intermediate web splicing device 6 are arranged upstream of the first corrugated cardboard production device 4 . The first top web splicing device 5 comprises a first unwinding unit and a second unwinding unit, the first unwinding unit is used to unwind the discontinuous first top web from the first top web roll, and the second The unwinding unit is for unwinding the discontinuous second top web from the second top web roll. The discontinuous first and second top webs ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com