A construction method for the face protection structure of polywave type breakwater cast by pouring moulds.

A technology for pouring molds and construction methods, applied in breakwaters, buildings, embankments, etc., can solve problems such as the decline of the dam's wave-proof ability, the threat to the life and property of coastal residents, and easy damage, and achieve improved safety, strong wave resistance, and good wave resistance. The effect of the wave elimination function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

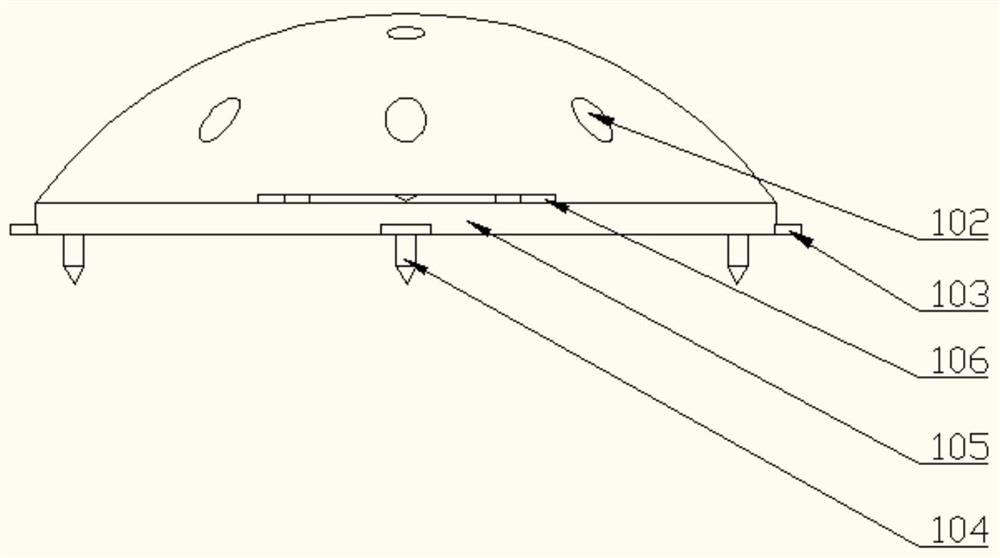

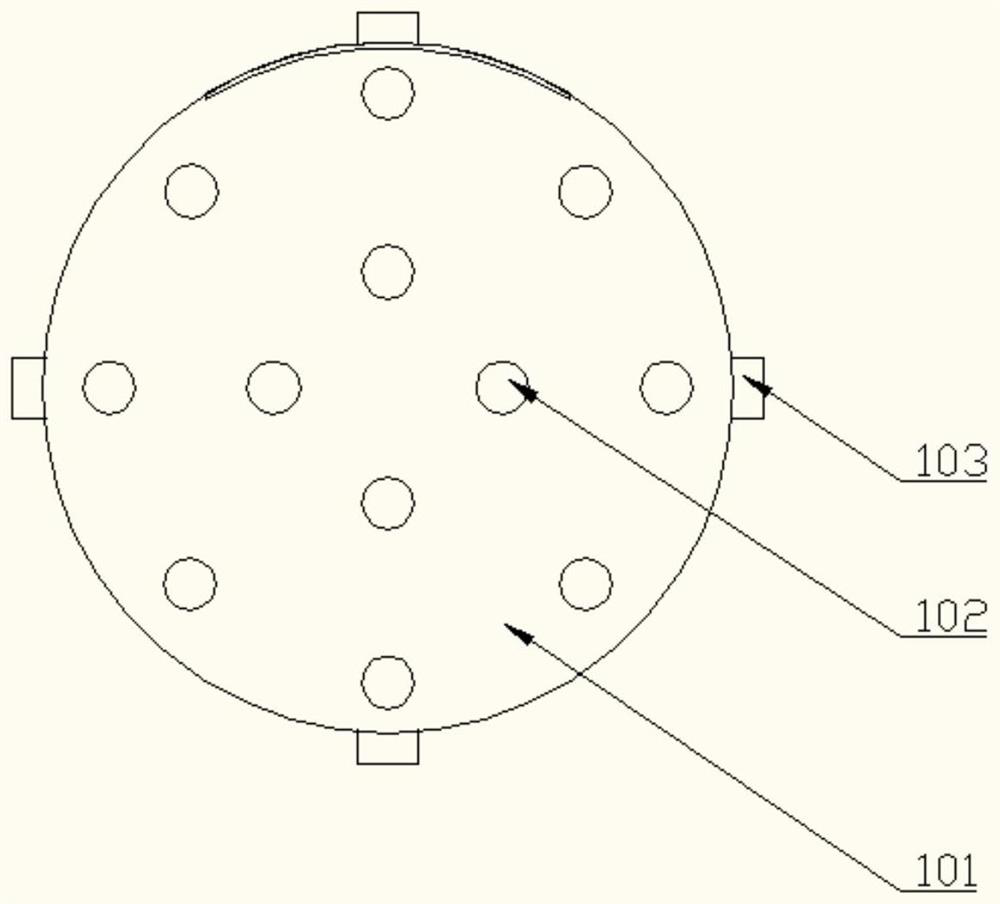

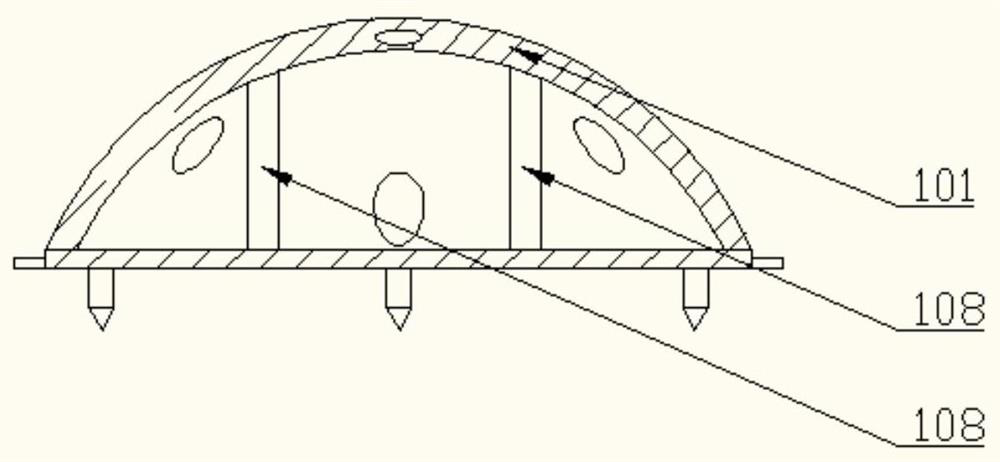

[0035] As shown in the figure, a wave-condensing breakwater protection structure includes a hollow arc-shaped body 101. The hollow arc-shaped body 101 is made by pouring concrete after binding the steel structure; The concentrating hole 102, after the sea wave washes to the outer arc surface of the central control arcuate body 101, the water flow enters the inner cavity of the hollow arcued body 101 from the converging hole 102, because the flow velocity near the flow concentrating hole 102 is greater than the water flow velocity on the water surface, so it will flow on the water surface A vortex is formed at the place to eliminate the kinetic energy of the wave;

[0036] The bottom side of the hollow arc-shaped body 101 is provided with a discharge groove 106 for draining the water flow entering the inner cavity; the bottom of the hollow arc-shaped body 101 is provided with a chassis 105 for sealing and sealing, and the chassis 105 is also a reinforced concrete structure; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com