Steel concrete column pile and construction method thereof

A technology for column piles and steel concrete is applied in the field of steel concrete column piles, which can solve the problems of poor stability of supporting columns and poor water-stopping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0051] This embodiment is to carry out specific construction to the steel concrete column pile in embodiment 1, and construction method specifically comprises the following steps:

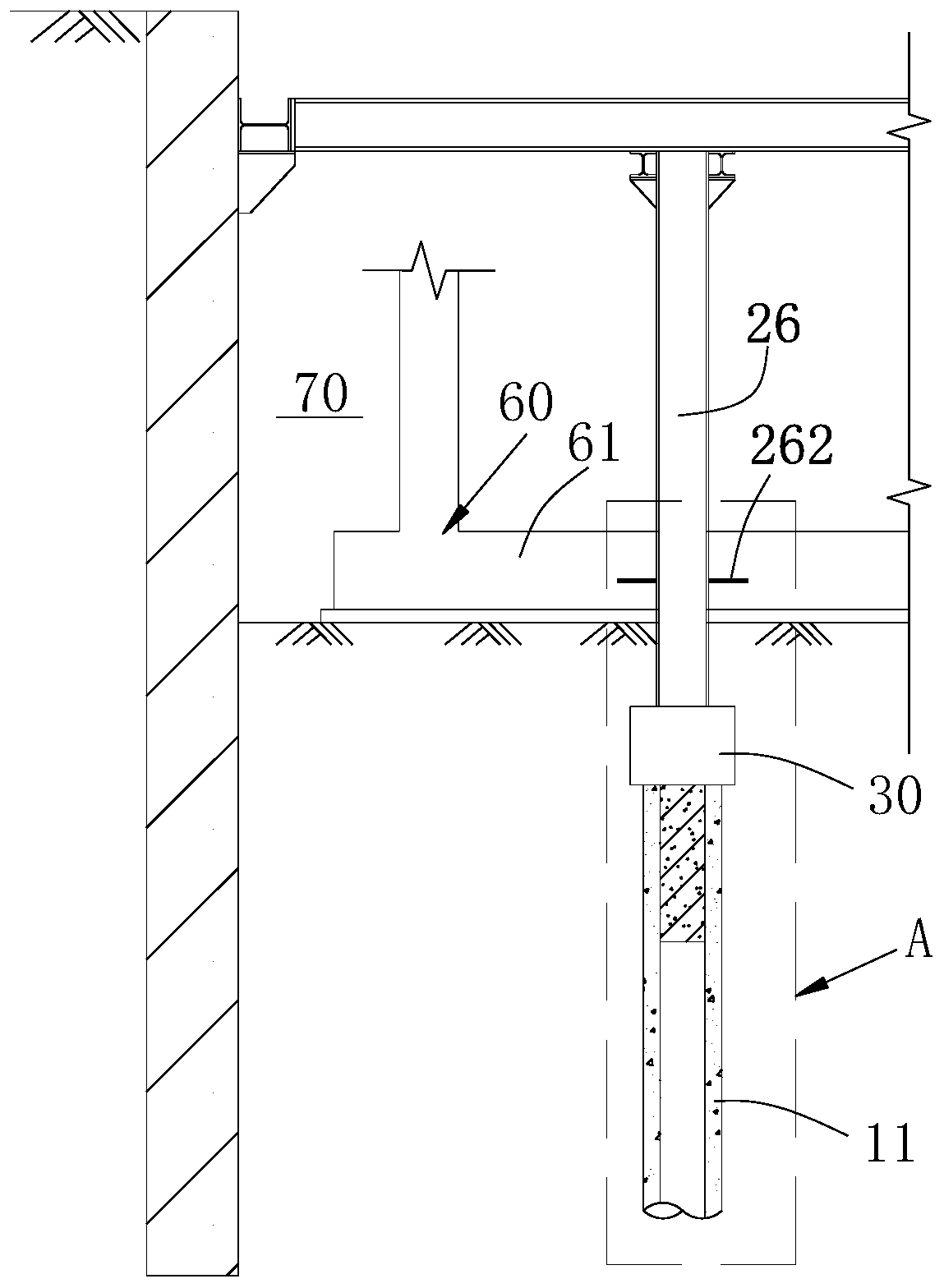

[0052] (1) Please refer to Figure 4 , before the construction steel concrete column pile, at first finish the construction of foundation pit enclosure wall 51, then construct steel concrete column pile.

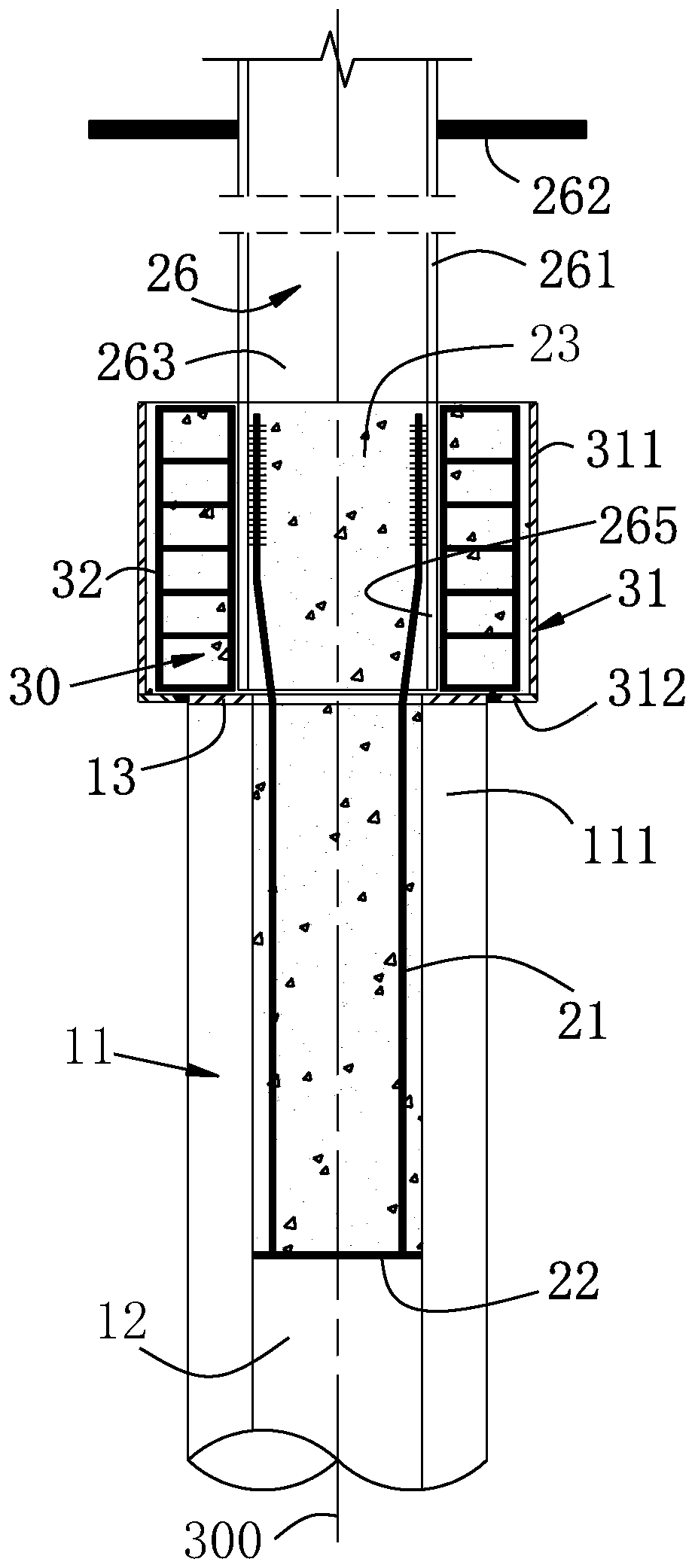

[0053] When constructing steel-concrete column piles, the prefabricated pipe piles 11 are first sunk at the setting position, so that the upper end of the prefabricated pipe piles is kept above the ground 100°, and the sinking of the prefabricated pipe piles is suspended. The upper end of the prefabricated pipe pile is the pipe pile connecting end 111 .

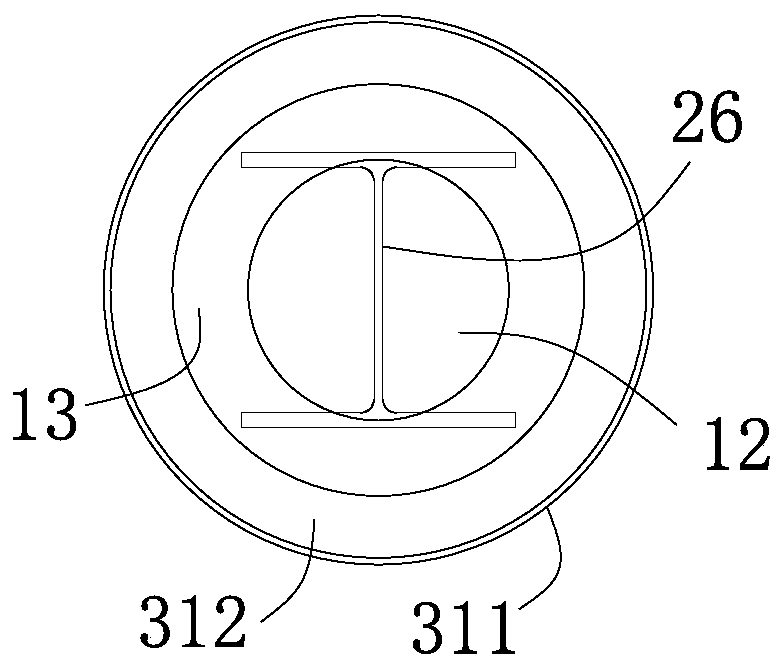

[0054] (2) See Figure 5 , welding the ring plate 312 of the steel cylinder 31 to the connecting end plate 13 of the prefabricated pipe pile 11 . Then the reinforcement cage 32 of the expansion part is placed in the steel cylinder 31, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com