Suspending device for mounting industrial gas pipeline

A pipeline installation and industrial gas technology, applied in the direction of pipeline brackets, pipe components, pipes/pipe joints/pipe fittings, etc., can solve the problems of poor vibration buffering effect, improve buffering effect, avoid stability and firmness, and increase adsorption The effect of the bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

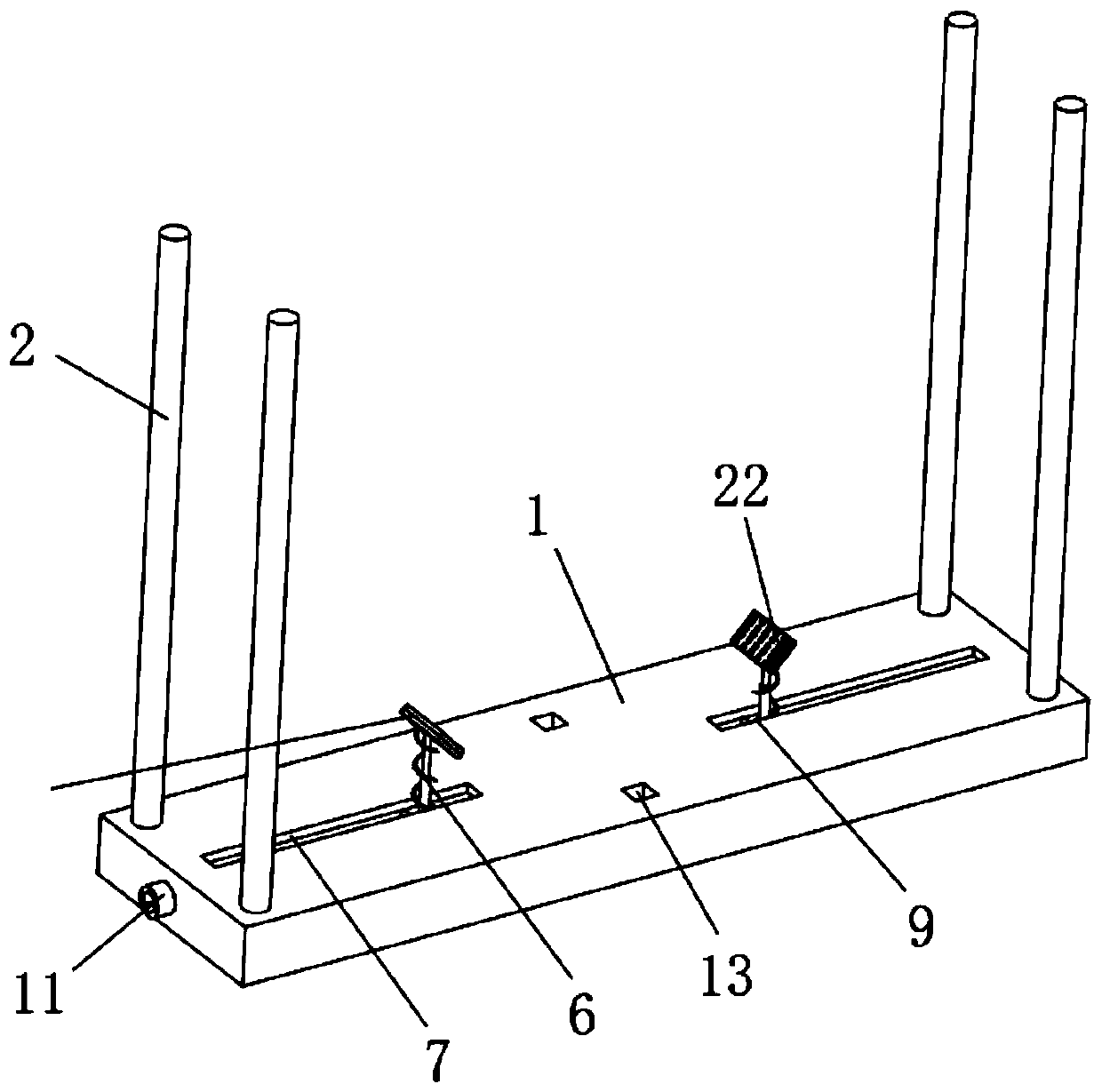

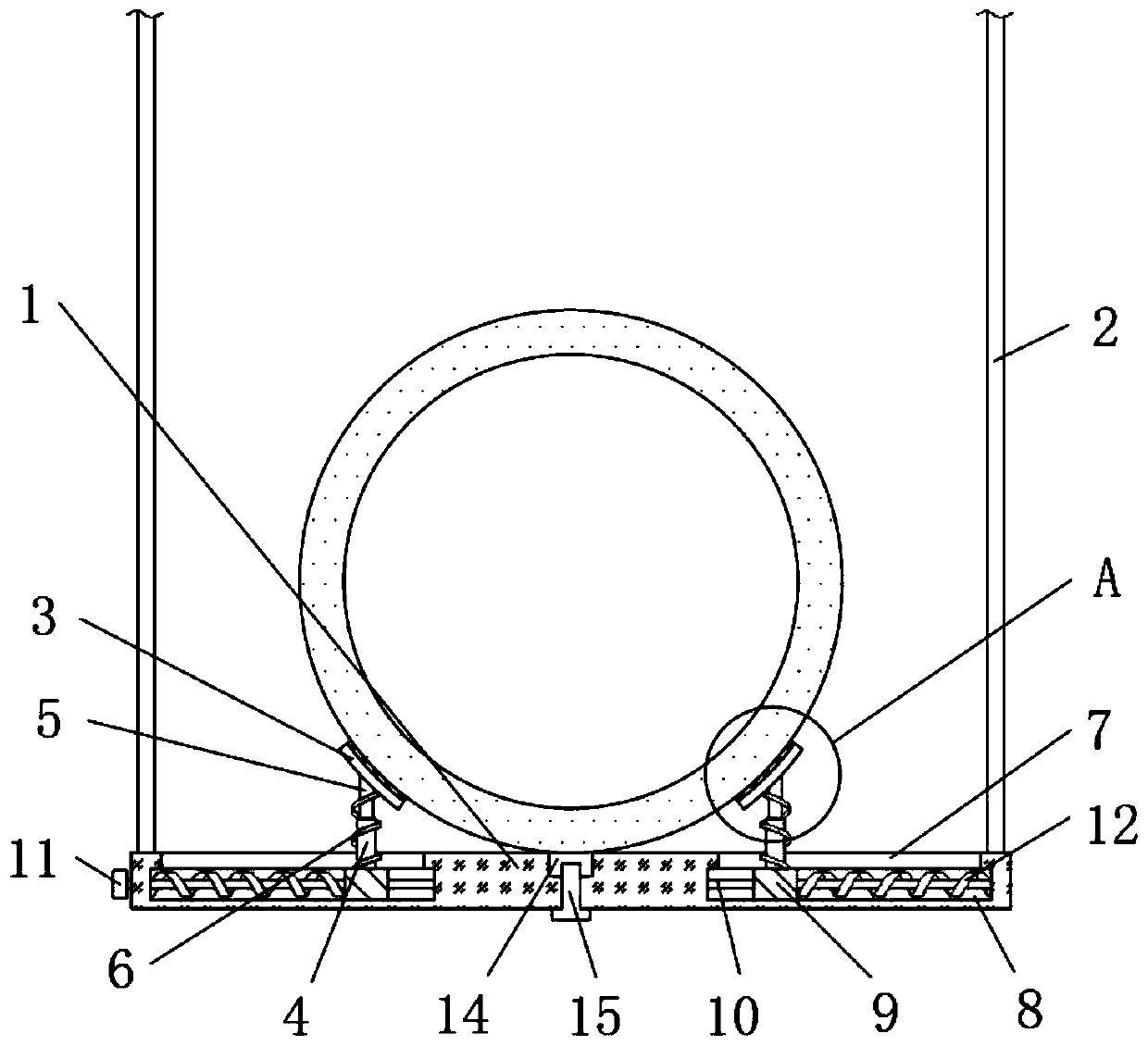

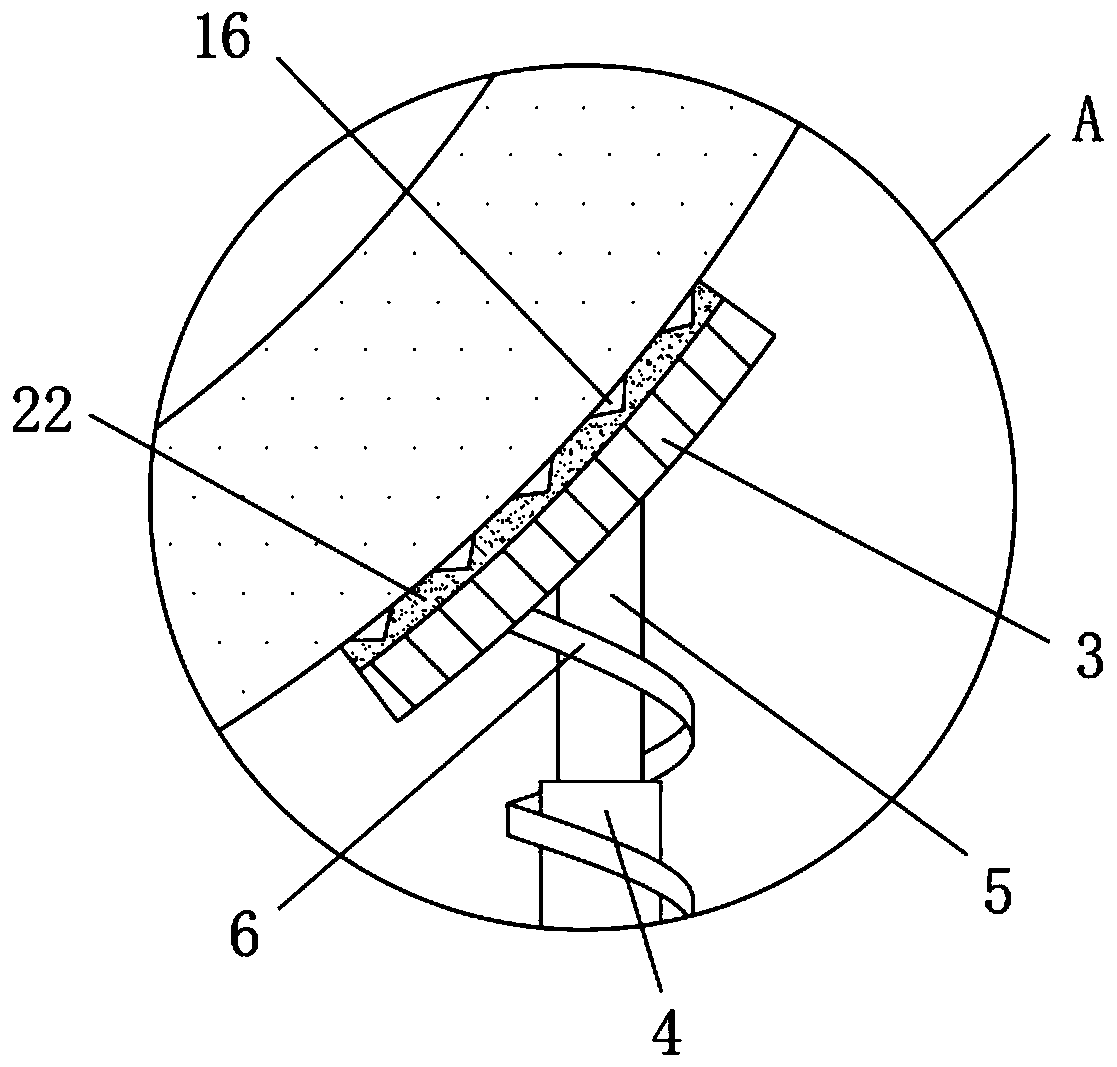

[0028] refer to Figure 1-3 , a suspension device for industrial gas pipeline installation, comprising a support frame 1 placed horizontally, fixing parts 2 are fixed on both sides of the top of the support frame 1, and a gas pipeline is arranged on the top of the support frame 1, and the top of the support frame 1 is located Both sides of the gas pipeline are provided with a clamping piece 3, and the side of the clamping piece 3 close to the gas pipeline is fixed with a rubber pad 22, the clamping piece 3 is inclined downward toward the side close to the gas pipeline, and the clamping piece 3 The side close to the gas pipeline is arranged in an arc-shaped structure. A sleeve 4 is fixed at the position corresponding to the top of the support frame 1 and the clamping piece 3, and the inner wall of the sleeve 4 is slidingly connected with a sleeve rod 5. The top end of the sleeve rod 5 is connected to the clamp. The bottoms of the holders 3 are fixedly connected, and a first spr...

Embodiment 2

[0036] refer to Figure 4-5 , a suspension device for industrial gas pipeline installation, the middle positions of both sides of the outer wall of the top of the support frame 1 are fixed with a fixed base 17, and the two ends of the top of the fixed base 17 and the fixed part 2 are fixedly connected with a second obliquely arranged Three springs 18, the top outer wall of the support frame 1 is located on both sides of the draw-in groove 13 and is provided with a storage groove 19, and the side of the bottom inner wall of the storage groove 19 close to the draw-in groove 13 is connected with an auxiliary support plate 20 by torsion spring rotation, and the auxiliary support plate A fourth spring 21 is fixedly connected between the bottom of 20 and the bottom inner wall of the receiving groove 19 .

[0037] During use, the bottoms of the two third springs 18 are connected to the fixing seat 17 on the top of the support frame 1, thereby increasing the fixed point between the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com