Vibration isolation support of marine precision measuring device

A precision measurement and vibration isolation support technology, which is applied to ship components, support machines, ship construction, etc., can solve the problems of reliability and accuracy, low accuracy of measurement results, and inability to set up and position, so as to maintain rigidity and stability performance, good vibration isolation effect, and the best vibration isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can more clearly understand how to practice the present invention. While the invention has been described in connection with preferred specific embodiments thereof, these embodiments are illustrative only and are not intended to limit the scope of the invention.

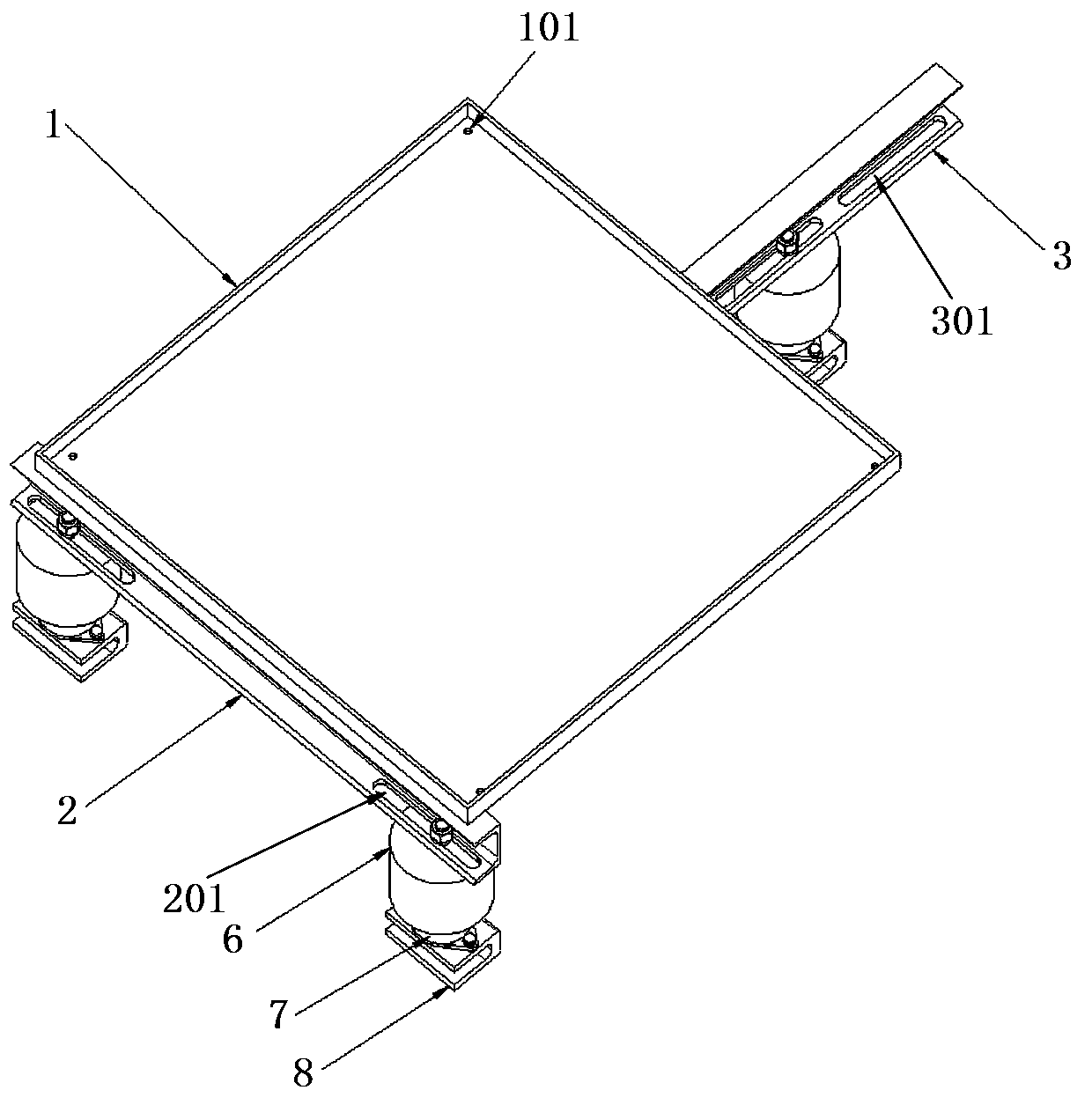

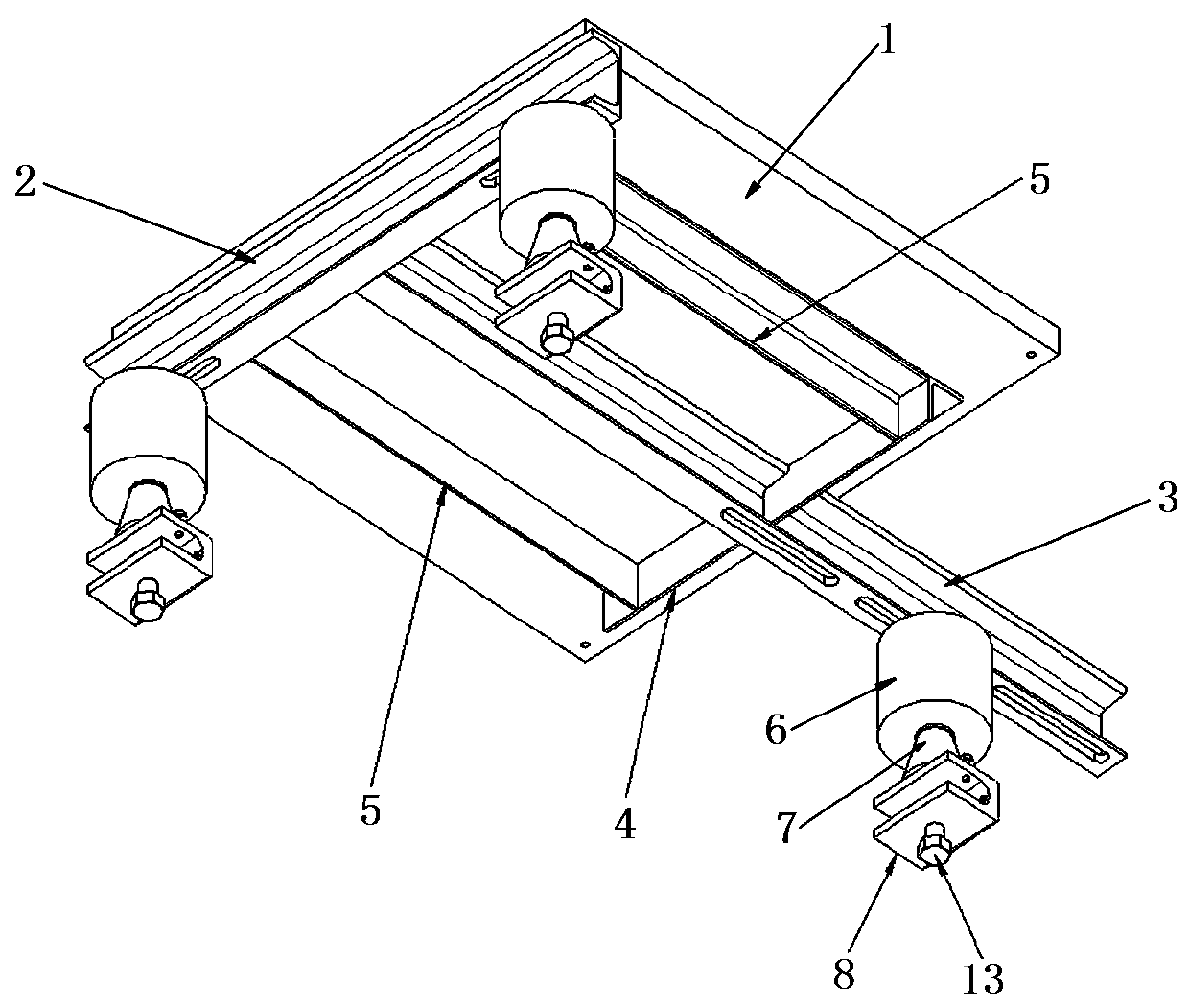

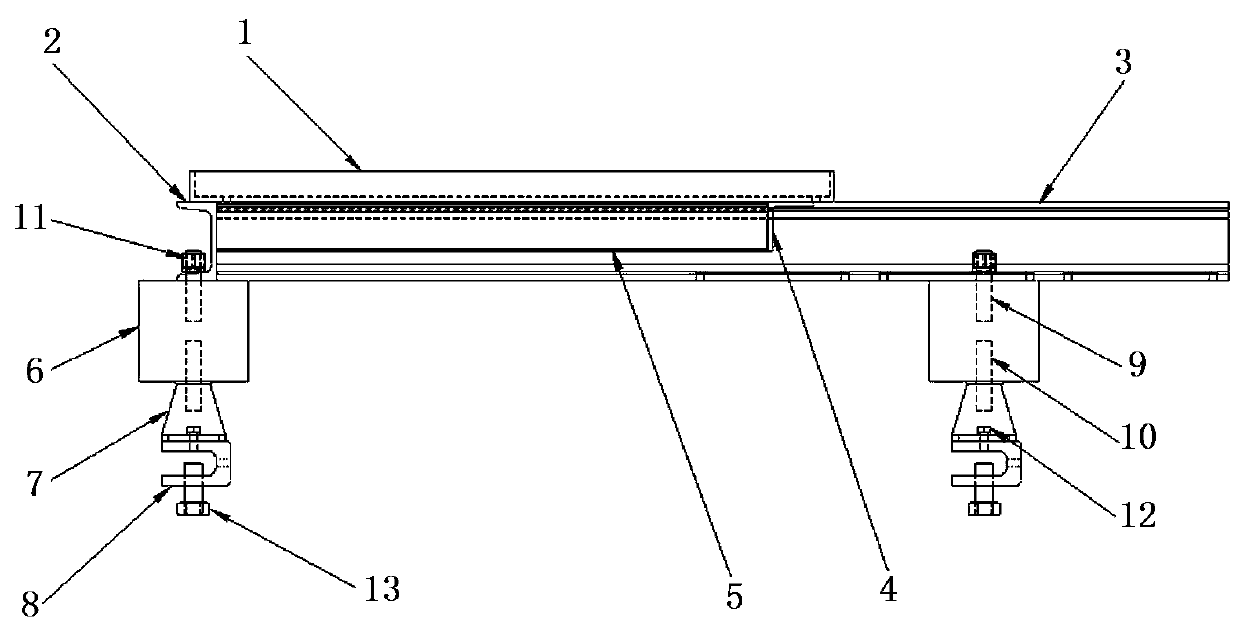

[0052] see Figure 1 to Figure 4 , a marine precision measuring device vibration isolation support, including a tray 1, a T-shaped bracket, an auxiliary bracket, three sets of legs.

[0053] The tray 1 is used to place the tripod of the precision measuring device. see figure 1 , the tray 1 includes a rectangular bottom plate and a surrounding edge. The edge of the rectangular bottom plate is provided with a surrounding edge for preventing the tripod from slipping. Four corners of the rectangular bottom plate are provided with a drain hole 101 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com