High-heat-resistance coil gun armature structure

A coil gun, high heat-resistant technology, applied in the field of coil guns, can solve the problems that the structure design of the coil gun armature is rarely mentioned, and achieve the effect of weakening the eddy current effect, increasing the outlet speed and reducing the quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In step (1), high-purity pure copper with high-density twins is prepared by pulse electrodeposition using copper sulfate (CuSO4) as the electrolyte. The average grain size is 400nm, the twin sheet length is between 100nm and 1000nm, and the average twin sheet thickness is 15nm.

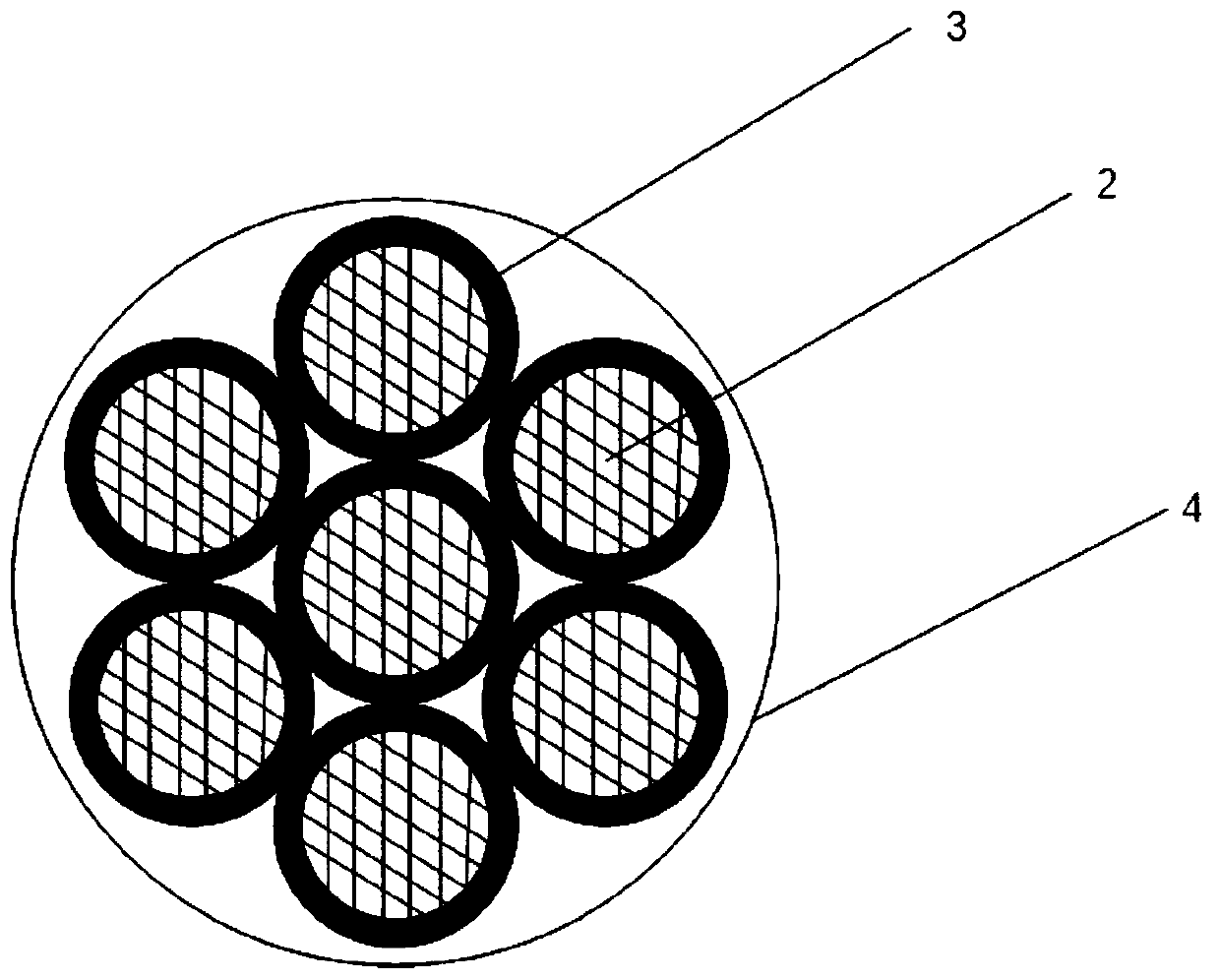

[0038] Step (2), adopt the nano-twinned copper in the step (1) to make copper wire, the cross-sectional diameter of copper wire should be slightly less than 2 times of current skin depth in the armature coil, guarantee that the whole cross-section of copper wire can play To achieve effective conduction, the diameter of the copper wire should be less than 2.1mm when the excitation current is 1000hz. Such as figure 1 As shown in 2, where 2 is the cross section of the copper wire, and also the actual distribution of the current in the copper wire.

[0039] In step (3), wrap a layer of polyimide (PEEK) or C / CSI composite material on the outside of the copper wire in step (2), so as to prevent cur...

Embodiment 2

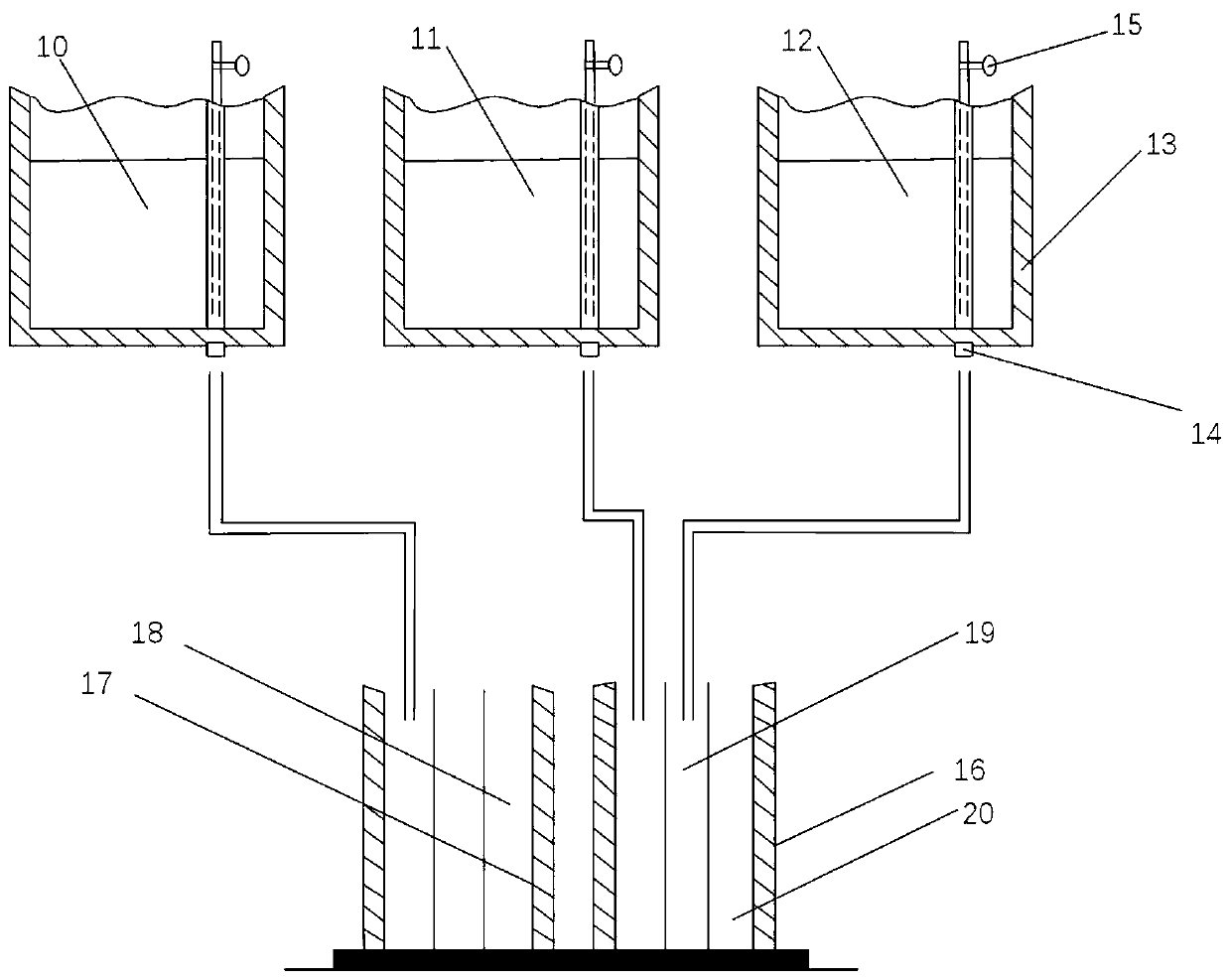

[0045] Step (1), in different ladles, hold alloy liquids with different composition ratios, such as image 3 As shown, 13 is a ladle, 10 is a copper alloy liquid with an aluminum content of 7%, 11 is a red copper alloy liquid, and 12 is a copper alloy liquid with an aluminum content of 2%.

[0046] In step (2), the alloy liquid with different components in step (1) is cast in a multi-nozzle method, and the mold is cast, such as image 3 As shown, 14 is the water outlet, 15 is the control valve, 16 is the outside of the mold, 17 is the inside of the mold, 18, 19, and 20 are respectively the inner casting area, the middle casting area and the outer casting area. Region 20 is cast using molten alloy 10 , region 18 is cast using molten alloy 11 , and region 19 is cast using molten alloy 12 . After the casting is completed, a layered annular alloy ingot is formed, the resistivity of the material inside the alloy ingot is low, and the resistivity of the material outside the alloy i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com