Current parameter calibration system and method based on standard electromagnetic valve and oscilloscope

A technology of current parameter and calibration system, applied in instruments, measuring electrical variables, measuring devices, etc., can solve problems such as damage to special measuring equipment, and achieve the effect of simple structure, simple circuit structure, and accurate calibration results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with the accompanying drawings and specific embodiments, the specific implementation of the present invention, such as the various components involved, the mutual position and connection relationship between each part, the function and working principle of each part, etc. will be further described in detail.

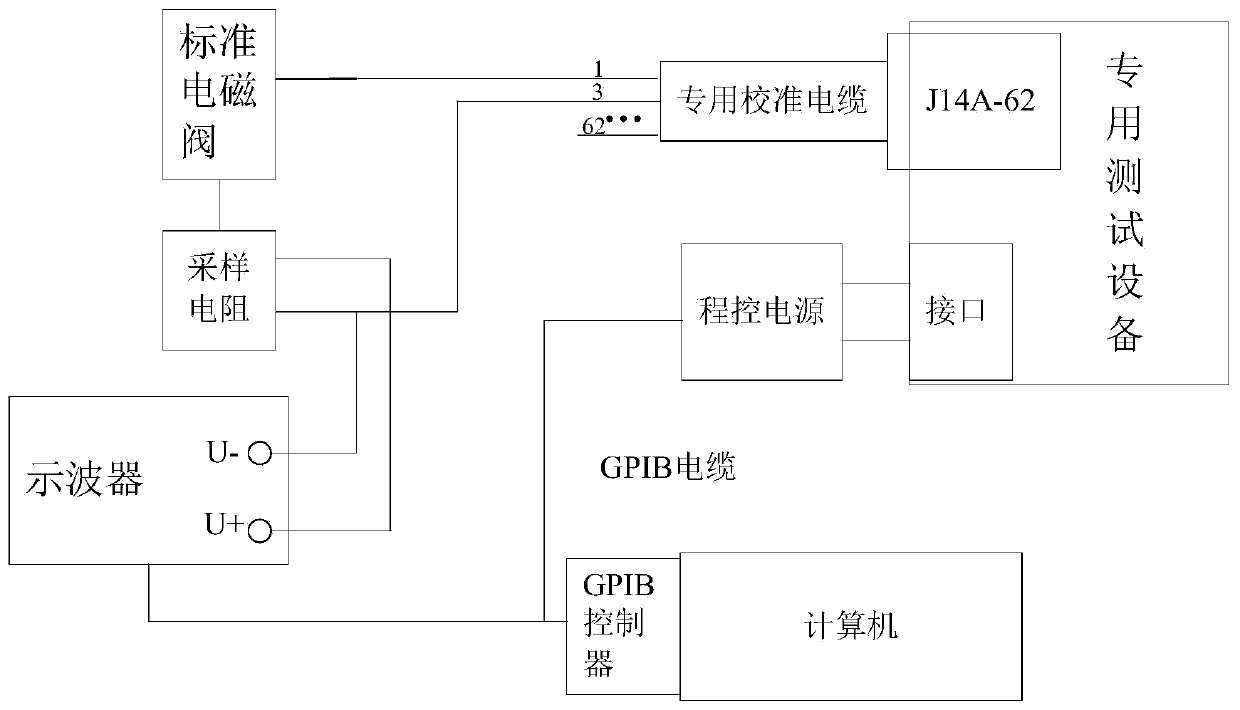

[0030] from figure 1 It can be seen that the current parameter calibration system based on standard solenoid valves and oscilloscopes in this embodiment mainly includes standard solenoid valves, sampling resistors, oscilloscopes, GPIB controllers, programmable power supplies, dedicated calibration cables, computers and host computer software. The special test equipment to be calibrated includes 50 sampling channels, and the dedicated calibration cable is a multi-core cable, the number of cable cores corresponds to the number of sampling channels, and one of the cable cores is a common cable core.

[0031] The program-controlled power supply, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com