Negative plate, preparation method and lithium-ion battery comprising negative plate

A technology of negative electrode sheet and lithium ion, applied in the field of preparation method and lithium ion battery including the same, and negative electrode sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

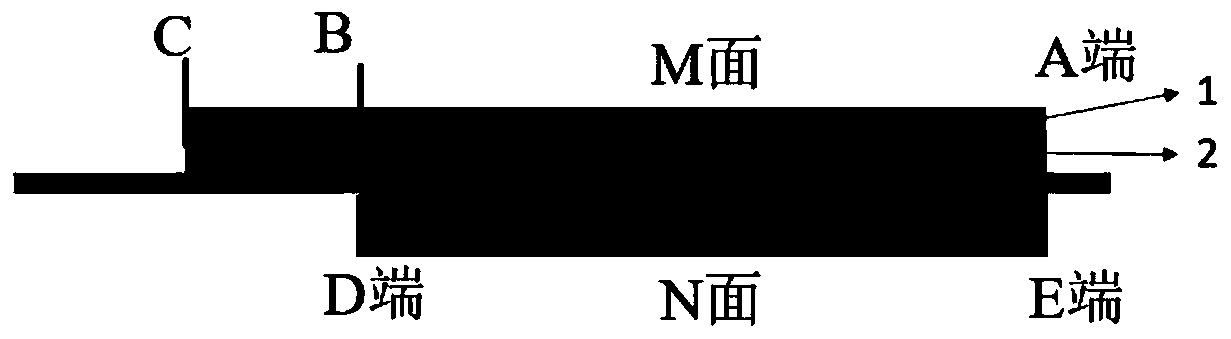

Image

Examples

Embodiment 1

[0067] The first step: prepare the slurry that forms the first negative electrode active material layer: the first negative electrode active material (artificial graphite), the first conductive agent (conductive carbon black) and the first binder (sodium carboxymethyl cellulose) According to the mass ratio of 97:1.5:1.5 into the stirring tank, adding deionized water to prepare the slurry forming the first negative electrode active material layer, the solid content of the negative electrode slurry is 40wt% ~ 45wt%; wherein, the first The particle size distribution of the negative electrode active material is: 3μm10 50 90 <13μm;

[0068] The second step: prepare the slurry forming the second negative electrode active material layer: the second negative electrode active material (artificial graphite), the second conductive agent (conductive carbon black) and the second binding agent (sodium carboxymethyl cellulose) According to the mass ratio of 97:1.5:1.5 into the stirring tank,...

Embodiment 2-3 and comparative example 1-2

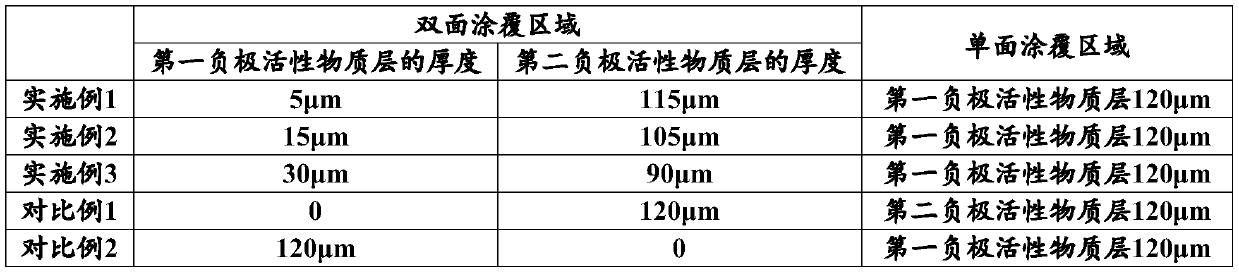

[0075] Other operating steps are the same as in Example 1, the difference is only in the thickness of the single-sided coating area, the thickness of the first negative electrode active material layer and the second negative electrode active material layer in the double-sided coating area are different, specifically as shown in Table 1 .

[0076] The structural parameter of the negative plate of table 1 embodiment 1-3 and comparative example 1-2

[0077]

[0078] The negative electrode sheets prepared in each example have the same compaction, and will be assembled into a soft-pack battery cell model 386283, and the energy density will be tested at 0.2C / 0.2C charge and discharge at 25°C. The core was charged at 2.5C / discharged at 0.7C at 25°C, and the battery was disassembled at different cycles to confirm the lithium deposition on the single-sided coating area of the battery negative electrode and the lithium deposition on the negative electrode surface. The disassembly r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com