Fuel cell flow field structure, cathode plate, fuel cell bipolar plate, and fuel cell

A fuel cell and cathode plate technology, which is applied to fuel cells, circuits, electrical components, etc., can solve the problems of difficult manufacturing processes, related mechanisms are yet to be studied, and it is difficult to change the water adhesion to the wall of the flow channel, so as to improve the flow rate. Tao effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

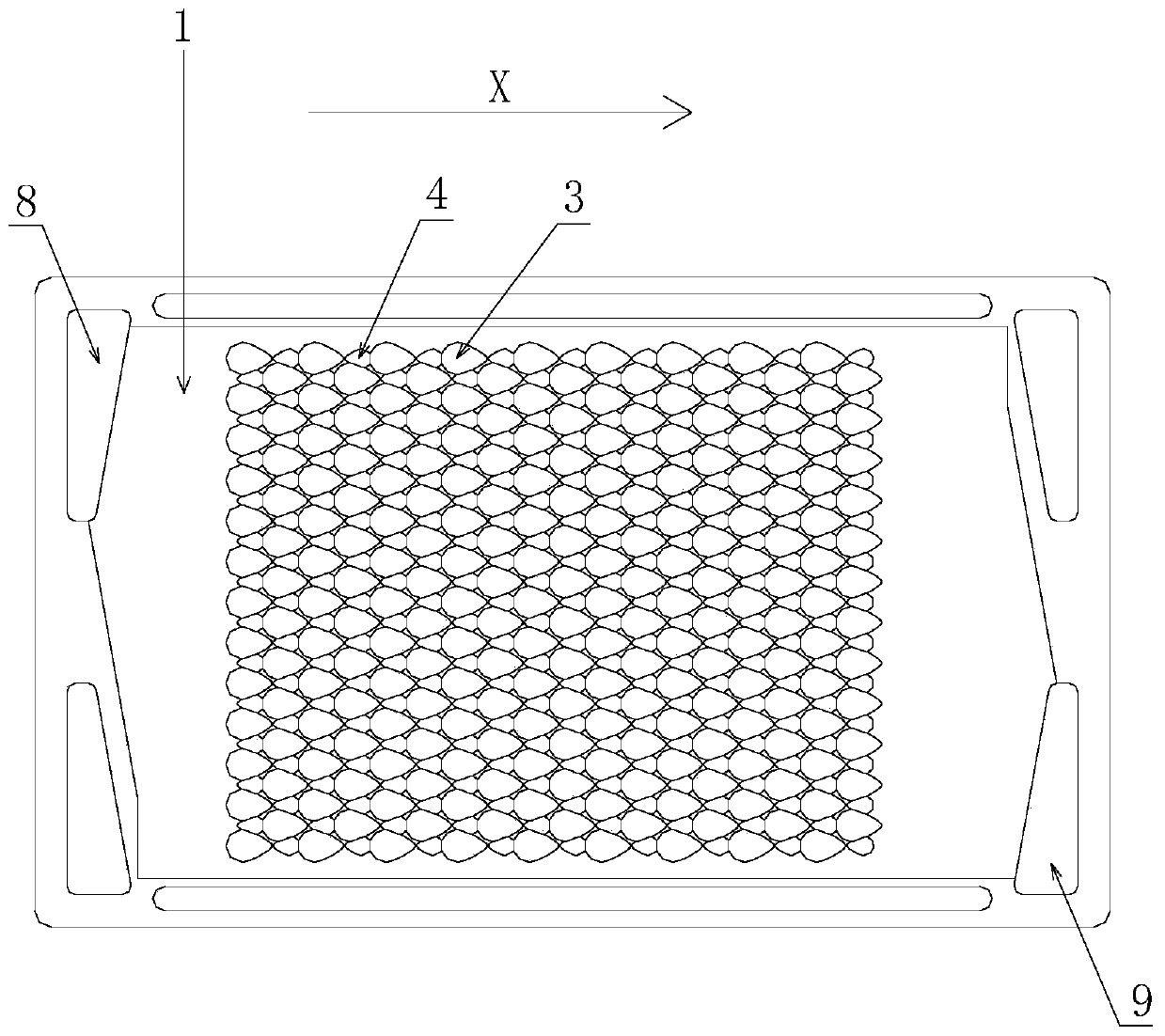

[0082] Embodiment 1, a fuel cell bipolar plate, which includes: a cathode plate 1, an anode plate;

[0083] Wherein, the cathode plate 1 (using a rectangular metal plate) is provided with an air inlet 8 and an air outlet 9, and the air inlet 8 and the air outlet 9 are arranged at the corners of the cathode plate 1, and the air inlet 8 and the air outlet 9 are opposite Corner line setting;

[0084] Wherein, the middle part of the cathode plate 1 is provided with a flow field structure;

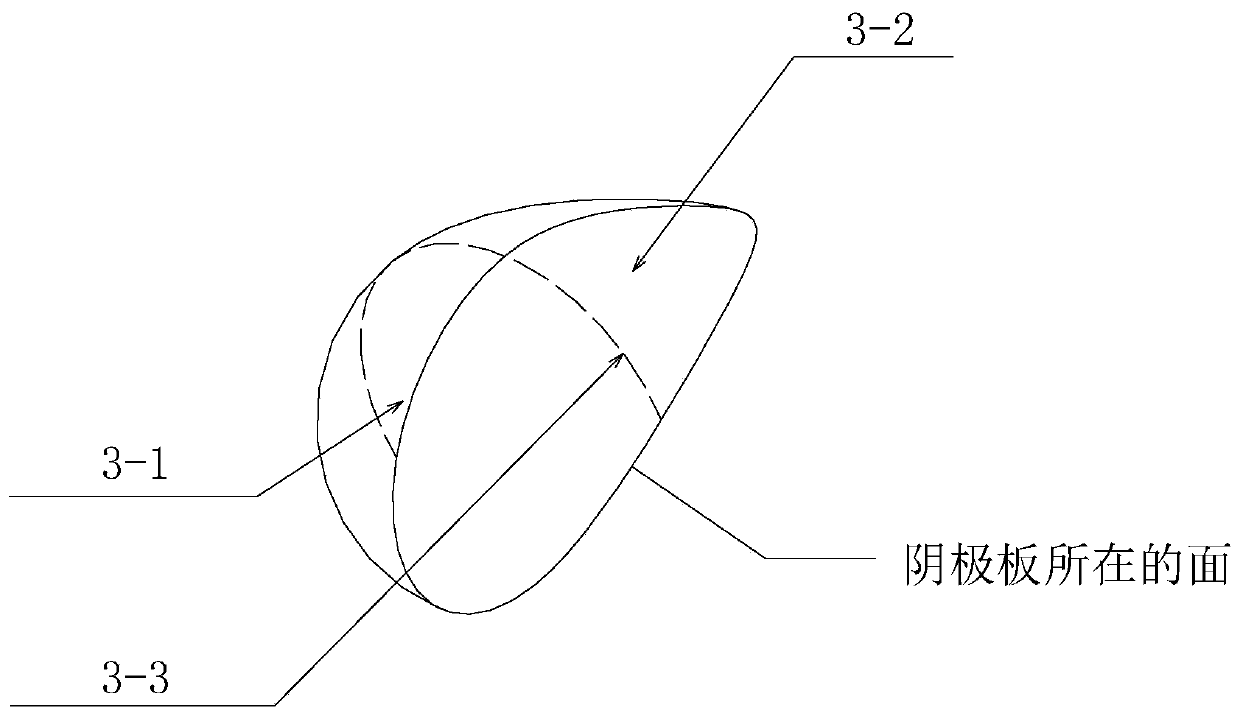

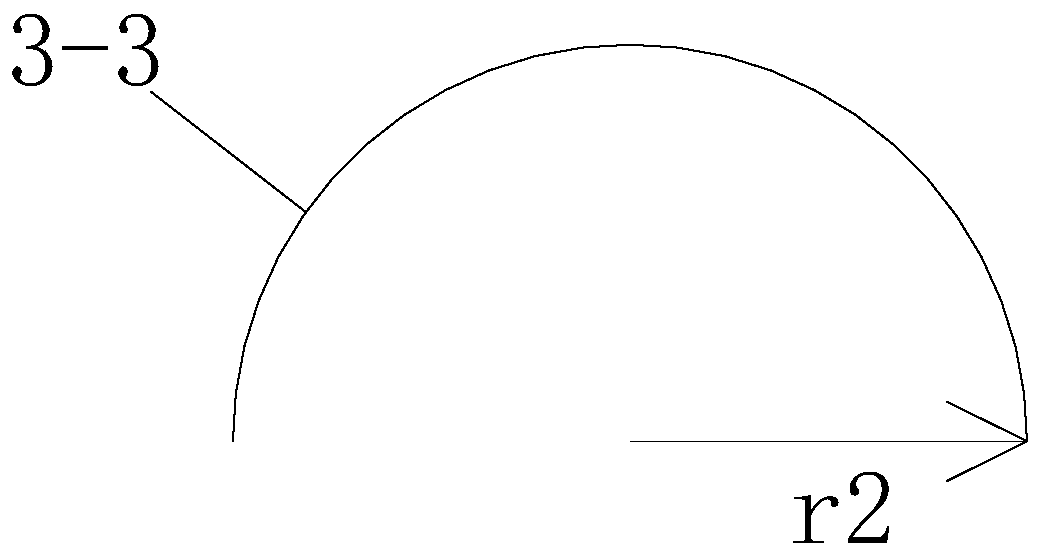

[0085] The flow field structure includes: an array of semi-droplet-shaped projections on the cathode plate, and an array of semi-droplet-shaped depressions on the cathode plate;

[0086] The cathode plate semi-drop-shaped projection array includes: several cathode plate semi-drop-shaped projections, and the cathode plate semi-drop-shaped projections are arranged in a quincunx shape;

[0087] The array of semi-drop-shaped depressions on the cathode plate includes: several semi-drop-shaped depr...

Embodiment 2

[0118] Embodiment two: if Figure 7-8 As shown, a plurality of first flow guide partitions 14 are arranged on the air inlet 8 side of the cathode plate, Figure 8 is in Figure 7 Improvements are made on the basis of the above, and a part of the first air guiding baffle 14 is arranged in an arc shape, so that the tail end of the first air guiding baffle 14 is parallel to the X direction, and furthermore, the air flow direction is also in the X direction.

[0119] Compared with the first embodiment, the second embodiment is more in line with the aerodynamic design.

[0120] A computer simulation test was carried out for the scheme of Example 2, as shown in Figure 9-11: when equilateral triangles are distributed, at different heights from the cathode plate, the air flows in the flow gap relatively uniformly, and no turbulent flow occurs. Phenomenon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com