Sheet-type contact element jack structure

A contact and hole structure technology, applied in the direction of contact parts, fixed/insulated contact components, parts of connection devices, etc., can solve problems such as increasing retention force and number of contacts, low assembly and production efficiency, and complex processing technology , to achieve the effect of increasing the holding force, reliable connection and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

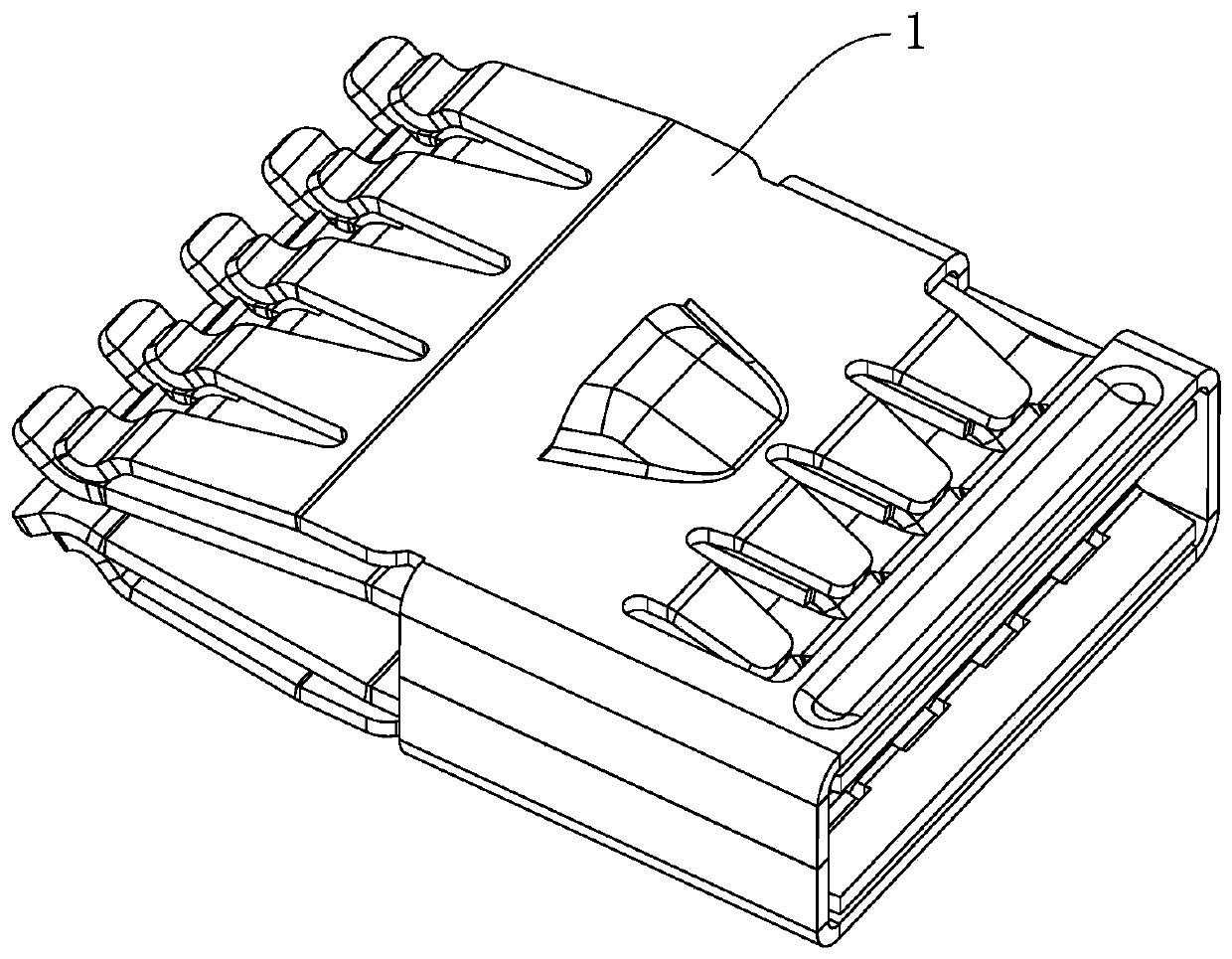

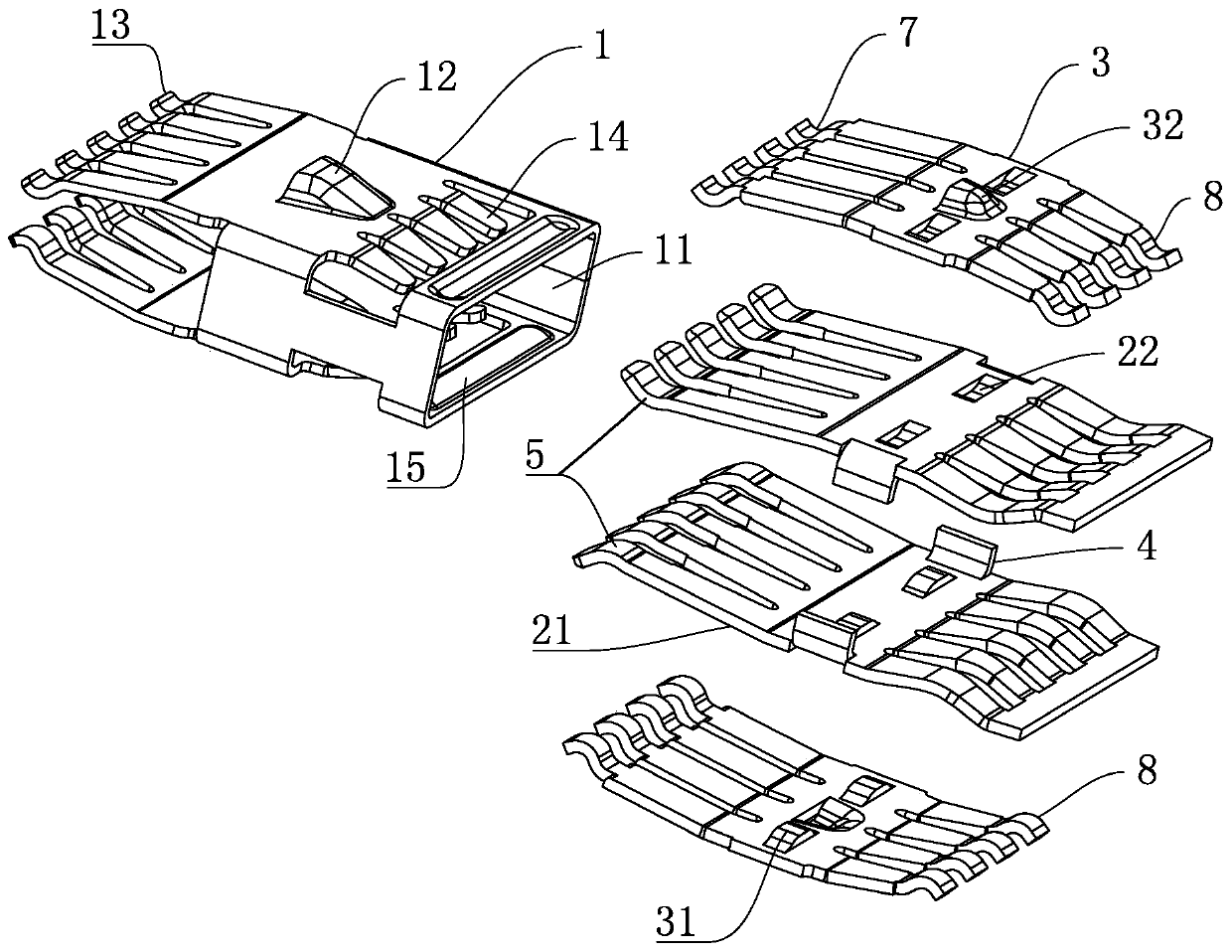

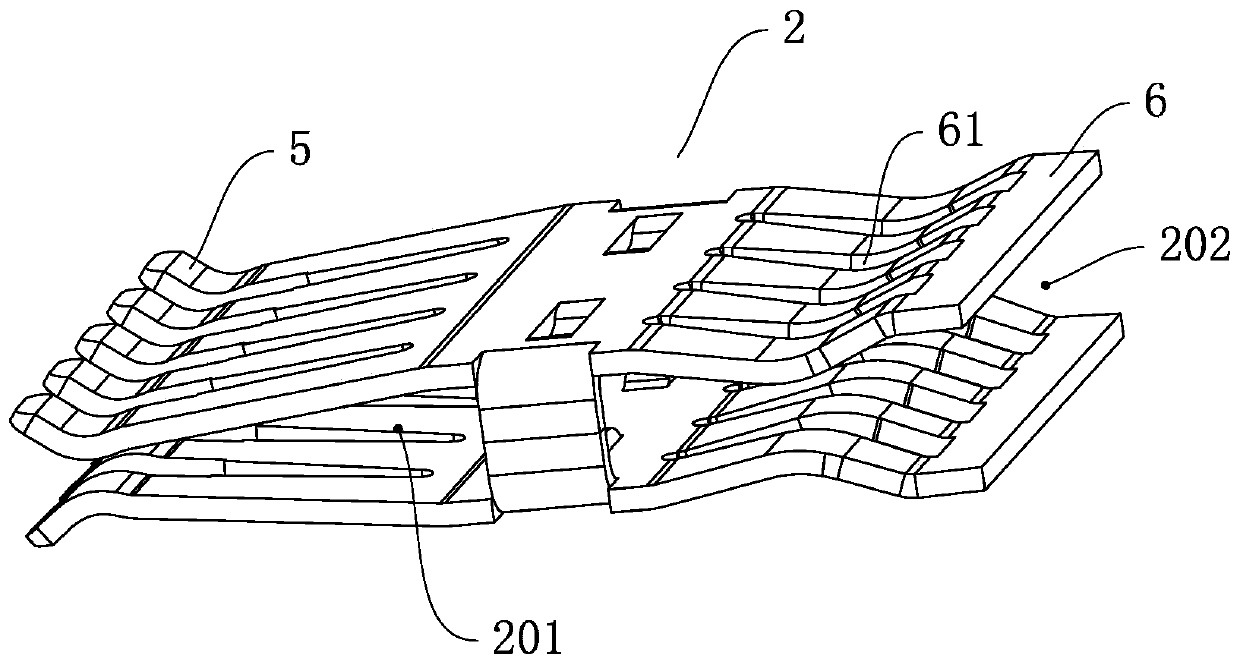

[0032] Such as Figure 1 to Figure 7 As shown, the socket structure of the chip contact piece of the present invention includes a circlip 1 and a chip contact assembly 2 installed in the circlip socket 11 and both ends of which can be mated with the adapter chip pins. And the reeds 3 located on the upper and lower surfaces of the leaf contact assembly, the reeds are provided with two and symmetrically distributed, used to increase the number of contact contacts with the adapter sheet pins; the leaf contact assembly 2 includes two symmetrically spliced In this embodiment, both sides of the middle part of the sheet contact are bent to form the contact portion 4, and the two contact portions abut against each other through the end planes of the contact portion. The front end of the chip contact assembly is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com